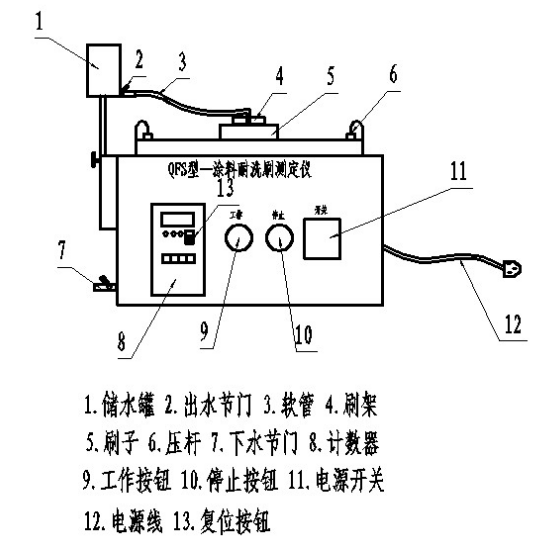

Working principle and main structure

1. The motor makes the brush reciprocate and linearly move through the mechanical transmission mechanism to complete the cleaning process of the test plate. The functions of setting, displaying and test termination of washing times are realized by the control circuit.

2. The instrument is mainly composed of motor, transmission structure, brush parts, water supply system, test plate pressing device and circuit control system.

Preparation before use (refer to the structure diagram)

1. At the specified room temperature of 23±2°C, place the instrument stably on the workbench, insert the rubber hose on the drain valve (7), and pass it into the container or the drain device.

2. Dissolve washing powder in distilled water to make a 0.5% (by mass) solution, with a pH value of 9.5-10, as the washing test medium, and other media specified in product standards can also be used. Pour the prepared medium into the water storage tank (1) for later use.

3. Immerse the bristles of the brush in water at about 20 ℃, 12mm deep, shake off the water vigorously after 30 minutes, then immerse the bristles in the prepared washing medium, 12mm deep, 20 minutes, the brush can be used after this treatment .

4. The preparation of the test sample shall be carried out according to the provisions of Article 4 of GB/T9266-88. It is recommended to use the wet Film Applicator produced by our company to form the film.

5. The power supply needs to be single-phase AC 220v, 50HZ, with a protective grounding power supply, and a leakage protector should be installed at the same time.

Test operation steps (refer to the structure diagram)

1. Turn up the brush holder (4), put the painted surface of the sample to be tested upwards, put it on the test bench, pull up the pressing rod (6), and put it down after twisting it at an appropriate angle, then press the test plate, and Put the treated brush (5) into the brush holder (4).

2. Insert the power supply (12) into a 220v single-phase power socket with protective grounding, press the power switch (11), the counter will display "0" or "1", connect the preset counting key to make it reach the required number of repetitions . Then press the reset key (13).

(Note: Do not reverse the above order, so that the instrument is in standby mode)

3. Adjust the outlet valve (2) to drip 0.04g of washing medium per second to keep the surface of the test panel moist.

4. Press the working button (9) to start the test, and stop working automatically after the specified number of times. Close the outlet door and pull up the brush holder. Take off the test plate to complete a test process.

Test plate inspection and result evaluation

1. The number of times of washing can be set in advance, or the number of times used to wash until the primer color is exposed in the 100mm area in the middle of the test panel (in this case, the preset number should be selected larger).

2. Inspect the coating film in the 100mm area of the middle length of the test panel that has been washed under the scattered sunlight, and observe whether it is damaged and the color of the primer is exposed. One sample is subjected to equal tests three times, and the coating film of at least two test panels is not damaged and the background color is not exposed within the specified number of times of washing, it is considered that the washing resistance is qualified.

Precautions in use

1. It is strictly forbidden to touch various buttons on the counter during the test, so as not to damage the counter.

2. To stop the test, press the stop button (10) and the brush will stop working.

3. There is no primer on the bottom plate, but the counter has reached the predetermined value, and it will stop automatically. If you need to continue to work, just press the reset button, and then press the work button, the test will start again, if you change the set times, you need to press the reset button after pressing the number keys.

4. During the test, especially when loading and unloading the test plate and filling the medium, the medium should be prevented from flowing into the instrument (especially pay attention to the opening in the middle of the upper cover). If it flows in accidentally, you can wait for it to dry itself if it is a small amount. If it is a large amount, you should open the upper cover to dry the inflowing medium. Before use, it should be tested with a test pen or other means, and the appearance of the instrument should not be used with electricity.

5. After the test, all parts of the instrument should be cleaned for the next use.

Instrument Maintenance

1. After using the instrument for half a year, check the lubrication condition of the gearbox. Loosen the two M5 screws in the middle of the brush holder (4), remove the brush holder, loosen the four corner screws of the upper cover, and open it to the left to replace the oil in the gearbox.

2. Inject high-viscosity engine oil into the conduit hole of the instrument sliding frame.