① According to the nature of production, it can be divided into two types: intermittent song type and continuous type. Spray booths for intermittent production are mostly used for the coating of single pieces or small batches of workpieces. Multiple spraying equipment can also be concentrated next to the production line for large batches of small workpieces. According to the way the workpieces are placed, they are divided into desktop and hanging types , Table mobile three. Most of the spray booths for batch production are semi-open. Continuous production spray booths are mostly used for coating large quantities of workpieces, and generally use transport machinery such as through-type electric suspension conveyors, electric rail trolleys, and ground conveyors to transport workpieces. The spray booth for continuous production can form an automatic coating production line together with pre-painting pretreatment equipment, coating film curing equipment, and transportation machinery.

②According to the airflow direction and ventilation mode in the painting room, it can be divided into four types: horizontal ventilation, vertical ventilation, bottom ventilation, and upward and downward ventilation. The indoor airflow direction is in the horizontal plane and passes through the side direction perpendicular to the moving direction of the workpiece, which is called horizontal ventilation, which is mostly used for small spray booths with separate ventilation; the airflow direction in the horizontal plane and parallel to the moving direction of the workpiece is called longitudinal ventilation; indoor airflow If the direction is perpendicular to the moving direction of the workpiece in the vertical plane , it can be divided into two types: bottom draft and up-supply and down-supply. Since it can form a stable air flow, it is a commonly used structure for spray booths.

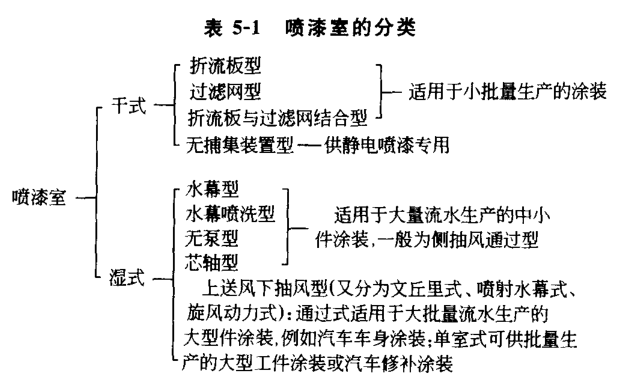

③According to the treatment method of paint mist, it can be divided into two categories: dry type and wet type. The dry spray booth is to directly capture the paint mist with the airflow and then collect and process the paint mist through the filter material or equipment; the wet spray booth is to capture the paint mist with water and other liquids, and then treat the waste liquid containing the paint mist . Since the dry spray chamber does not use water to collect paint mist, there is no waste water and no secondary pollution. Ventilation equipment requires low air pressure, small air volume, and low operating costs, but it has paint mist collection efficiency, easy accumulation of paint particles on the inner wall and baffles of the spray booth, and serious pollution of the equipment itself that requires frequent cleaning. Moreover, the filter material used needs to be replaced frequently, which increases the cost, and there is also the risk of fire, so it can only be used in a production environment with a small amount of paint . Wet spray booths have high efficiency in collecting paint mist, and are safe and clean, but the operating costs are high, and the water containing paint mist is treated , which requires high air pressure of the fan, high energy consumption of the fan, and paint Consumption is also a big disadvantage . At present, large-scale spraying uses wet spray booths.