1. Scope and description

Adhesion is the fastness of the paint film to the substrate. This method is to fix the template on a front and rear movable platform. When the platform moves, the stylus moving in a circle can scratch the paint film, and can draw overlapping circular rolling lines. The integrity rating of the paint film, expressed in grades.

2. Instruments and Materials

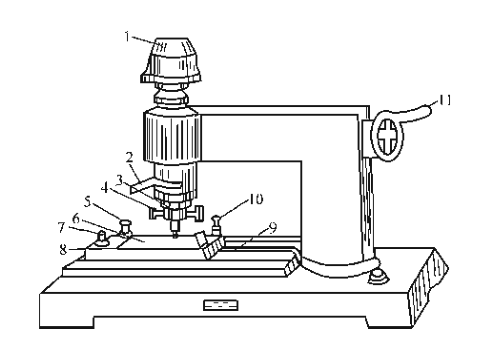

(1) The adhesion Tester is shown in Figure 1-4-26. The end distance of the lead screw of the instrument test bench is 1.5mm, and its rotation is synchronized with the rotating needle; the rotating needle adopts Sanwu brand stylus, and the no-load pressure is 200g; weights can be placed on the load plate, and its mass is 100g, 25mm。 200g, 500g, 1000g3 rotary needle radius of rotation is adjustable, the standard radius of rotation is 5. 25mm.

(2) Quadruple magnifying glass.

(3) The width of the paint brush is 25~35 mm.

3. Measurement method

(1) Check the needle of the adhesion Tester before testing, if it is not sharp, it should be replaced. Lift half of the nut, pull out the test bench, and the needle can be replaced.

(2) Check again whether the scratches match the standard radius of gyration, if not, adjust the radius of gyration. The adjustment method is to loosen the bolts behind the needle plate and the adjustment bolts for the radius of gyration. After moving the needle plate appropriately, tighten the above bolts one by one, compare the scratches with the standard circular rolling line diagram, and adjust until the standard radius of gyration is 5. The 25mm round rolling line is the same. See Figure 1-4-27 for the relevant parts .

(3) When measuring, put the painted surface of the sample on the test bench, tighten the adjusting bolts to fix the sample, move the lifting rod backward , so that the tip of the rotating needle touches the paint film, and shake the sowing handle evenly in a clockwise direction, The rotation speed is preferably 80~100r/min, and the standard length of the circular rolling line scratches is (7.5±0.5)cm.

(4) After scratching, move the elevating bar forward to lift up the clamp plate, loosen the relevant bolts that fix the sample plate, take out the sample plate, remove the paint chips on the scratches with a paint brush, check the scratches with a four-fold magnifying glass and grade them .

Note: If the scratches do not expose the bottom plate, weights should be added as appropriate.

4. Result presentation

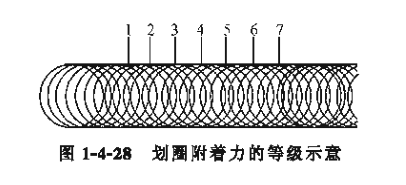

Take the upper side of the upper scratch on the model as the inspection target, and mark seven parts 1, 2, 3, 4, 5, 6, and 7 in sequence. Correspondingly divided into seven levels, as shown in Figure 1-4-28. Check the completeness of the paint film of each part in order. If more than 70% of the grids of a certain part are intact, the part is considered to be intact, otherwise, it should be considered damaged. The adhesion of the paint film is indicated by the lowest level of the intact paint film. The result is based on the same level of at least two samples, the first level is suitable, and the seventh level is the worst.

5. Reference standard

National Standard GB/T 1720 "Determination of Paint Film Adhesion".