This article is a selection case of a user choosing a laboratory coater. The user wants to scrape PCB ink on the PET carrier film. The thickness of the PET carrier film is about 10um, but it is relatively soft and difficult to keep flat. membrane. In addition, the thickness of the coating film is 18um-20um after drying, and the solid content is about 70%.

According to the user's substrate situation, just choose a laboratory coater with vacuum adsorption function to meet the customer's needs. In addition, according to the user's coating film thickness and solid content parameters, it is estimated that the required wet film thickness ranges from 22.9 to 32 microns. According to the overall situation, the technical engineer of NBCHAO suggested the following set of experimental coating equipment selection list.

| Film making and proofing equipment- Film making | |

| RDS 14# 3/8" Coating stick 3/8" |

| Specification parameters: production process wire winding type, wet film thickness 32.0μm, diameter 9.52mm, total length 400mm, coating width 300mm, hand grip width 50+50mm, material stainless steel, steel wire diameter 0.36mm | |

| RDS 13# 3/8" coating stick 3/8" |

| Specification parameters: production process wire winding type, wet film thickness 29.7μm, diameter 9.52mm, total length 400mm, coating width 300mm, hand grip width 50+50mm, material stainless steel, steel wire diameter 0.33mm | |

| RDS 12# 3/8" coating stick 3/8" |

| Specification parameters: production process wire winding type, wet film thickness 27.4μm, diameter 9.52mm, total length 400mm, coating width 300mm, hand grip width 50+50mm, material stainless steel, steel wire diameter 0.30mm | |

| RDS 10# 3/8" Coating stick 3/8" |

| Specification parameters: production process wire winding type, wet film thickness 22.9μm, diameter 9.52mm, total length 400mm, coating width 300mm, hand grip width 50+50mm, material stainless steel, steel wire diameter 0.25mm | |

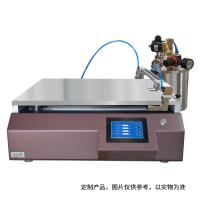

| Zhongyi Instrument TBJ-A3 Wire Rod Vacuum Adsorption Coating Testing Machine |

| Specification parameters: Coating method wire rod coating, coating base size 300*400mm, coating width 300mm, coating speed 1~140mm/s infinitely variable speed, coating thickness range according to different wire rod specifications, temperature display accuracy ± 2 ℃, the configuration of the Vacuum Pump is external, the vacuum adsorption size is 300*400mm (customizable), the vacuum aperture is Φ1.2mm, the key control method is touch screen control, the regulator display accuracy is ±0.001mm, the display is digital display, the total power consumption is 2060W, Host power supply 220V 50Hz, external dimensions 690*410*520mm, overall weight 65Kg, bottom plate made of aluminum alloy | |