After the paint film coated on the substrate is bent under the action of external force, its comprehensive properties such as toughness (elasticity, plastic performance) and adhesion are called flexibility, also known as flexibility. The ability of a coating to regain its shape after stress has been removed is sometimes referred to as elasticity or toughness. The flexibility of the coating film is closely related to factors such as the adhesion, tensile strength, and time impact properties of the coating film, is determined by the composition of the coating film, and is related to the time and speed of the coating film to detect deformation. The surface of an object is covered by a thin film, which is often affected by external forces that deform it. For example, drastic changes in external temperature will cause thermal expansion and contraction of objects. If the coating film is not tough enough, the coating film will crack. If the adhesion is not strong enough, the coating film will detach from the surface of the object.

The determination of the flexibility is mainly to detect the elongation at break through the joint force bending of the coating film and the substrate, which also includes the interface effect between the coating film and the substrate. There are three main types of instruments currently used to measure the flexibility of paint films: shaft Tester GB/T1731-79 paint film flexibility test method, cylindrical bending test device GB/T6742-86 film bending test device (cylindrical bending ), cone bending test device GB/T118-89 paint film bending test device (cone bending). Arbor rods are commonly used.

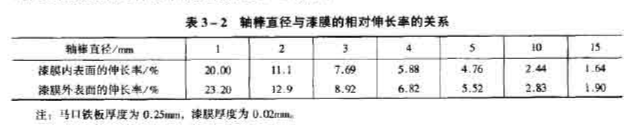

The national standard GB/T1731-79 "Determination of Flexibility of Paint Film" stipulates the use of the shaft Tester. It consists of 6 steel shafts of different thicknesses, each shaft is 35mm long, and the radius of curvature is 0.5, 1, 1.5.2, 2.5, 5, 7.5 mm, and each shaft rod. The test method is to bend the painted tinplate sheet on a shaft with a certain diameter. The bending action needs to be completed within 2 to 3 seconds, and then use a 4 times magnifying glass to observe the coating film. If there is no crack, it will pass. The diameter in mm means that the coating film will not be damaged after the shaft rod is bent. When the paint film is bent on shafts with different diameters, the relationship between the shaft diameter and the relative elongation of the paint film is shown in Table 3-2.