The principle of sampling is to sample as little as possible and to be representative.

definition

(1) A collection of paper or cardboard of the same kind and character. The packing unit of the batch is specified according to the product standard.

(2) Sample a rectangular piece of paper or cardboard according to the specified dimensions. The rectangle is drawn from the entire pattern or product, and the entire pattern is drawn from the selected packaging unit.

(3) All samples in the average sample set are average samples.

(4) Sample A is used as a certain number of paper or cardboard samples measured according to the prescribed inspection method. A sample is taken from a sample, sometimes the sample itself, or multiple samples.

(5) Random sampling. The sampling method used should allow each part of the population to have an equal chance of being selected.

principle

Select a number of product packaging units from a batch of paper and cardboard. And draw ten whole paper samples from it. The selected paper samples are then subdivided and blended to provide specimens that meet various test requirements.

1.3 Sampling steps

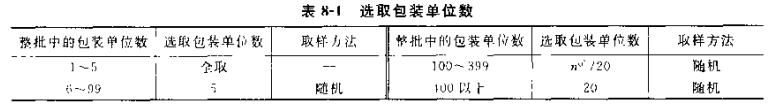

Select the packaging unit for sampling according to Table 8-1. The packaging unit should be undamaged and fully packaged.

1. When calculating the number of packaging units to be sampled. Remainders less than 20 are ignored.

3.1 Selection of the whole sample

Take the whole sample from the selected packing unit. The method is as follows.

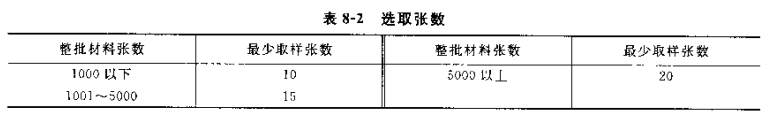

(1) Sampling of flat paper. Samples are drawn according to the total number of sheets of the selected packaging unit. The numbers are shown in Table 8-2.

(2) Sampling of roll paper: Remove all damaged paper layers from the outside of the roll, and then remove three layers (quantity not exceeding 225 g/m2) or one layer (quantity exceeding 225 g/m2) in the undamaged part ). Cut along the full width of the reel with a knife, the depth of which should be able to meet the number of sheets required for sampling, so that the cut paper samples are separated from the paper roll. From each stack of cut paper samples, randomly take the same number of paper samples, The sampling method is shown in Table 8-2. The number of sheets of the whole batch of materials is equivalent to the total number of sheets of the corresponding size that can be cut out from all rolls.

(3 ) Sampling of coil paper: remove the paper web with damage, wrinkles or other appearance paper defects on the outside of the coil, cut paper strips with a length of 5-10 m, and select from the total paper strips as shown in Table 8-2 Randomly take the required samples.

3.2 Sampling selection and cutting

(1 ) Flat paper or cardboard, one sample is cut from each whole sample, and the sampling positions are different.

(2 ) Roll paper or cardboard Cut a sample from each entire sample, the sample is the full width of the roll, and the width is 400 mm. The entire sample taken according to Table 8-2 is the average sample, and the number of average samples should be sufficient to meet the needs of taking samples.

additional requirements

Samples need to be kept flat, unwrinkled, out of direct sunlight, humidity fluctuations, and other detrimental influences. Be careful when touching the sample by hand, as it will affect the chemical, physical, optical, paper surface and other properties of the paper sample.

Each sample should be marked clearly. The vertical, horizontal and front and back sides of the paper should be accurately marked.

When sampling or testing, if there is an accident, it is necessary to re-sample. New samples should be taken as described above. Unless otherwise specified, the samples can be taken in the same packaging unit.

Sampling report

The sampling report should state the following points: the name of the sampling person, the sampling period I, and the sampling location ; the product name, paper number, quantification and production date of the sample taken ; the name and address of the production unit ; the name and address of the user unit ; the status of the batch , the number of units in the batch, the number and number of selected packaging units ; the number of sheets sampled from each packaging unit; any deviation from sampling.