Basis weight is an important indicator of paper and board. Quantitative size is directly related to many properties of paperboard. However, in order to save raw materials and increase the unit area, the paper weight should be reduced as much as possible under the premise of ensuring performance.

definition

The mass per square meter of paper or cardboard, expressed in g/m2.

principle

Measure the area of the sample and its mass, and calculate its mass per square meter.

instrument

(1) For sample cutting equipment, experimental paper cutter or special sample cutter, it is required that the error range of at least 95 times out of every 100 times should be within ±1% when comparing the area of the cut sample with the specified area. Equipment should be calibrated frequently [see 8.5.4]. If the precision has been achieved, use the average area obtained in the calibration test to calculate the quantification. If it is found that the cutting accuracy of the sample does not meet the requirements. The area of each sample should be measured separately to calculate the quantification.

(2) Balance: use a balance with an accuracy of 0.001 g if the sample weighs less than 5 g; use a 0.01 g balance if the sample weighs more than 5 g; use a 0.1 g balance if the sample weighs more than 50 g. When weighing, prevent airflow from affecting the weighing device.

Instrument Calibration

(1) Check the cutting area of the sample cutting equipment should be checked frequently, cut 20 samples, and calculate their area should reach the accuracy specified in (8.5.3). When the standard deviation of each area is less than 0.5% of the average area, this average area can be used for quantitative calculation in subsequent experiments. If the standard deviation exceeds this range, the area of each specimen shall be determined individually.

(2 ) Calibration of the balance, the balance should be weighed frequently with accurate standard weights for calibration, and a calibration table should be listed. Those that have been calibrated by the Metrology Bureau can be used within the valid verification period.

Experimental procedure

Sampling according to standard methods. The number of samples should not be less than 5. Their total area points are sufficient for at least 20 specimens. Temperature and humidity treatment was carried out according to standard methods. If measured under other conditions of temperature and humidity, the reported results shall state the condition of the sample at the time of weighing.

Fold along the longitudinal direction of the paper web into 1 layer, 5 layers or 10 layers. Then cut at least 4 stacks of samples of 0.01mm (disc with a radius of 56.4mm or 100mm×100mm) evenly along the transverse direction, with an accuracy of 0.1mm. If necessary, samples of 0.05 m² can be cut with an accuracy of 0.5 mm. If the sample cutting equipment cannot meet the accuracy requirements, the size of each sample should be measured to calculate the measurement area. Weigh the mass of each stack of samples separately, and cut out a total of 20 stacks of samples from at least 5 paper samples according to the above steps.

For coils with a width of less than 100 mm, five paper strips with a length of 300 mm should be cut according to the full width of the reel and weighed together. Measure the long and short sides of the weighed paper strips to an accuracy of 0.5 mm on the long side. The short side is 0.1mm, then calculate the area.

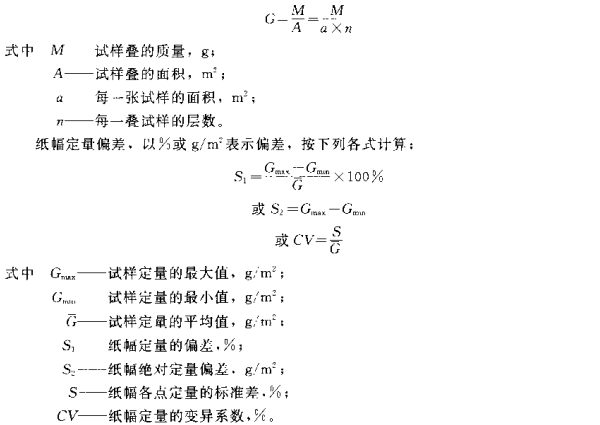

result calculation

The quantification of the sample is expressed by the mass (g) per square meter, as shown in the following formula