1. The error introduced by different coating materials

Copper, aluminum, chromium, etc. are usually tested coating materials, and their relative permeability are 0.99992, 1.000008 and 1.000045 respectively. Obviously, taking both as 1 is quite accurate. Therefore, the difference between them will not introduce measurement error. In addition, as long as the excitation frequency f is selected reasonably (selected during instrument design), the influence of conductivity can be controlled.

2. Effect of roughness

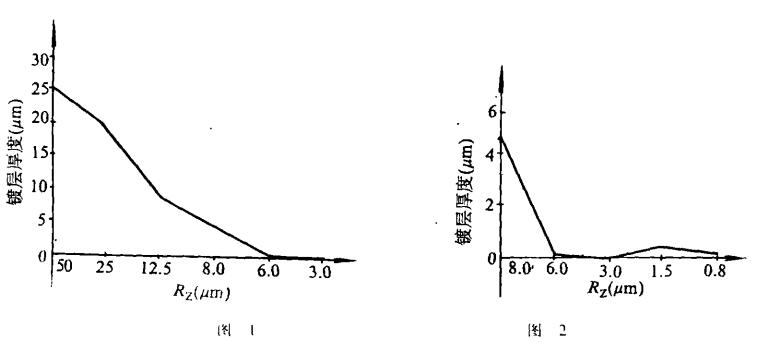

Due to the change of the substrate of the measured piece and the roughness of the measured surface, the measurement results are very different, so the real coating thickness value cannot be obtained. We made several sets of experiments, which are shown in Figure 1 and Figure 2 respectively.

The test results show that when the measured substrate and surface roughness Rz value is below 6.3 m (including 6.3 m), the influence on the measured results is negligible; when the roughness R. When the value is above 6.3 m, it will have a significant impact on the measured results. For the measured surface with wide tool marks, the measurement results are greatly affected by the position of the measurement point. For such a tested piece, take the average value of 4-5 measuring points as the measurement result, which can relatively reduce its influence. Different surface roughness directly changes the size of the magnetic circuit gap. The larger the roughness value, the larger the air gap, which increases the distance from the coil to the substrate, so the measured value increases. On the contrary, the measured value decreases and is closer to the real thickness of the coating

3. The influence of the measured substrate thickness

The thickness of the substrate used in calibrating the instrument is usually relatively large, and the thickness of the substrate under test generally varies greatly. When the base thickness of the measured piece is 10 mm, the influence of the thickness variation on the measurement results can be ignored. When the base thickness is less than 10mm, its influence cannot be ignored, especially when it is less than 3mm, its influence can already exceed 5% of the measured value. Therefore, when measuring thin workpieces, it is necessary to use a substrate calibration instrument with a thickness equivalent to the substrate to be measured. This is because, when the workpiece is thinner, the eddy current effect is greatly reduced, and the value of the measurement result is significantly increased. In order to solve the above problem, the thin DUT can be measured on a thicker substrate. Practice has shown that the influence of the eddy current effect can be avoided by doing so

4. Influence of radius of curvature

The calibration templates and calibration substrates used in eddy current Thickness Gauges are mostly planar, and the surface of the measured piece is often not a plane, but an outer circular surface or an inner hole surface. Such curved surfaces have a great influence on the measurement results. This is mainly due to the change of the probe (coil) and the measured surface air gap. For this reason, the measuring head can be measured along the axial generatrix, and satisfactory measurement results can be obtained. However, when the radius of curvature is small, in order to improve the accuracy of the measurement results, necessary tests should be done according to the specific conditions of the probe used. This is especially the case for quorum detection. For example, when we checked and accepted the hydraulic supports imported from Germany for the Ministry of Coal, we made proofreading parts in advance according to the radius of curvature of the tested parts, so that the acceptance work received satisfactory results.

5. The influence of the measured part

The test shows that the measurement results are different with different measurement locations, for example, near the edge and corners, the measurement results increase due to the reduction of the magnetic circuit cross-section and the decrease of the eddy current effect. Therefore, measurements near edges and corners should be avoided.

6 Influence of other factors

When the magnetic field strength is high enough and there are large electrical equipment on the testing site, it will have a certain impact on the instrument. Since the sensor itself has shielding measures, generally speaking, this effect is small. However, in order to ensure sufficient measurement accuracy, care should also be taken in actual use. The measured base material is different, and the relative magnetic permeability has a large change. Since the same base material is used for calibration, its influence on the measurement result is very small. It is necessary to press the probe and the surface of the measured object tightly to prevent the measured value from being unstable. Moreover, after the probe is pressed on the surface to be tested, slide it a little to eliminate the influence of dust and other dirt on the measurement results