The 20° angle measurement method is mainly suitable for high-gloss paper and paperboard such as cast-coated paper and glossy paper, and also suitable for high-gloss paper and paperboard printing samples, but not suitable for coating or paperboard with low gloss. Uncoated paper and board.

1 definition

(1) The nature of directional selective reflection on the surface of glossy objects, which determines the degree of strong reflected light or object mirroring that can be seen on the surface of the object.

(2) Specular gloss is the ratio of the luminous flux reflected into the specified aperture by the surface of the sample in the direction of specular reflection (regular reflection) and the reflected luminous flux of the standard mirror under interfering conditions, expressed as a percentage.

2 instruments

2.1 Composition of the instrument

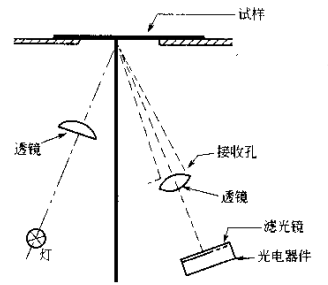

The optical system of the instrument is composed of light source, lens, sample pressure plate and photoelectric devices. The position, size and main characteristics of the main components are as follows.

(1) The size and relative position of the main optical parts, the distance from the light source filament to the lighting lens is 92 mm, the light diameter of the lighting lens is 37 mm, the focal length is 63 mm, the distance to the sample center is 70 mm, and the diameter of the test hole is greater than 25 mm. The diameter of the receiving hole is 11 mm, the distance from the center of the sample is 126 mm, the focal length of the receiving lens is 47 mm, and the distance from the receiving hole to the photoelectric device is 79 mm.

(2) Geometric conditions

The above dimensions can be modified so that the system meets the following geometric conditions. The angle of the incident optical axis to the normal of the sample is 20°±1°. The receiving lens, the receiving hole adjacent to the lens and the photoelectric device form a coaxial receiving system. If a flat mirror reflecting in the front is inserted at the sample position , the image of the filament is formed on the receiving hole. The diameter of the bright spot where the sample is illuminated is not greater than 1/4 of the distance from the sample to the receiving hole. The receiving hole is circular, and the opening angle of its diameter to the center of the sample is 5°, and the diameter of the filament image on the receiving hole is not greater than 2.5 ° and not less than 1° with respect to the center of the sample.

(3) Reduce stray light

The interior of the instrument is painted with matte black paint. The bulbs, lenses, photoelectric devices and the interior of the instrument should be kept clean and dust-free.

(4) Optical evaluation conditions

The overall spectral characteristics of the light source, filter and optoelectronic device should conform to the product of the C spectral power distribution of the illuminant and the CIE spectral light efficiency function, and the deviation should be limited to a change of 500 K in the color temperature of the equivalent light source.

(5) Optoelectronic devices

The photoelectric device and display circuit transform the received luminous flux into digital display, and the conversion accuracy should be within 1% of the full range in the whole range. 1/4 of the total area.

(6) Sample pressing plate

There should be no obvious stripes on the surface of the pressure plate, it should be matte black, and the flatness should be within 0.025mm. The pressure plate can open the suction switch while pressing the cardboard, so that a negative pressure is formed between the pressure plate and the paper pattern, and the paper pattern is sucked on the pressure plate to keep it flat.

(7) Schematic diagram of 20° angle gloss meter

2.2 Gloss standard

Theoretically, the standard of specular gloss is a flat mirror surface with perfect reflection , and its gloss value is set at 2037.6. According to this calculation, the gloss value of polished black glass with a refractive index of 1.567 is given by Fresnel (Fesnel) formula. 100 gloss units.

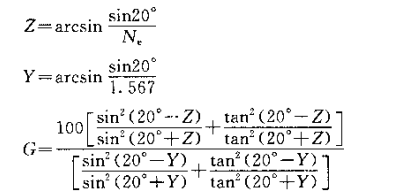

① Measure the refractive index Ne (refractive index of the mercury e spectrum line) of a black glass plate with a high-gloss working standard, and calculate the gloss value G of the working standard plate according to the following formula.

②Medium gloss standard plate. Objects with reflective characteristics similar to the tested paper sample, such as porcelain plates, can be used as medium gloss standard plates. The surface of the porcelain plate needs to be flat and the glossiness needs to be uniform. Each porcelain plate needs to be calibrated with a black glass standard plate on an instrument that meets the requirements of (8.14.2.2) to calibrate the gloss value.

③The standard board should be placed in a closed box when not in use, and kept clean to prevent contamination or damage to the surface. The working surface of the standard board should not be placed downwards to avoid dirt or wear. When holding the standard board, hold it by the edge of the board , so as not to stain the working surface of the standard board with oil and sweat on the hands. The standard board can be soaked in hot water and light washing liquid and gently washed with a soft brush (do not use soapy water). Then rinse with hot water near 65°C, rinse off the washing liquid, and finally rinse with distilled water, and dry in an oven at about 70°C. Black glass standards can be lightly wiped with lint-free lens tissue or other absorbent material, but medium gloss standards should not be wiped.

④ As a high-gloss standard black glass plate, after several years, the surface refractive index will gradually decrease, and the gloss value will also change accordingly. Therefore, it is recommended to be verified by the superior metrology department every 1 year, and it is better to re-polish the surface to restore its original state.

⑤Hei Jian with black velvet lining.

3 Preparation of samples

①According to standard methods, take samples, process samples, and test under standard conditions.

②Avoid watermarks, spots and visible paper defects from the extracted paper sheets, and cut 5 test pieces of 100 mm × 100 mm evenly along the transverse paper web, keep them clean, and do not touch the test surface with hands. (Sample gloss tends to decrease irreversibly in high humidity environments, so take care not to get the sample wet.)

4 Test steps and result calculation

① Turn on the power according to the instrument manual, and after preheating to the specified time, insert a black glass standard plate at the sample position, and adjust the reading to the calibration value of the standard plate.

② Put on the black letter and adjust the reading to zero.

③ Replace with a black glass standard plate to calibrate again, and then replace with a medium gloss standard plate to read the gloss value, the reading should be close to the calibration value of the standard plate. If the difference exceeds 1 optical degree unit, it is necessary to check the geometry, spectrum and optical meter characteristics of the instrument, or recheck the calibration values of the two standard plates.

④ After calibrating the instrument with the standard plate and black cylinder, insert the sample to read the gloss value. Unless otherwise specified, the front and back sides of each sample generally need to be tested in both vertical and horizontal directions. During the test, the instrument can be calibrated repeatedly with the standard plate and the black scale, and then checked again after the test to ensure that the instrument is always calibrated correctly.

⑤ Take the average value of the vertical and horizontal values for each side as the gloss value, and calculate the average value and coefficient of variation of the gloss of the front and back sides of 5 samples respectively, accurate to 1 gloss unit.