This method is mainly applicable to the 45° angle specular gloss of metal composite paper and cardboard such as aluminum foil paper and vacuum aluminized paper.

1 definition

(1) Gloss

The property of directional selective reflection on the surface of an object, which determines the degree to which strongly reflected light or the mirror image of the object can be seen on the surface of the object.

(2) Specular gloss

The ratio of the luminous flux reflected by the surface of the sample into the specified aperture in the direction of specular reflection (regular reflection) to the reflected luminous flux of the standard mirror under the same conditions. Expressed as a percentage.

2 instruments

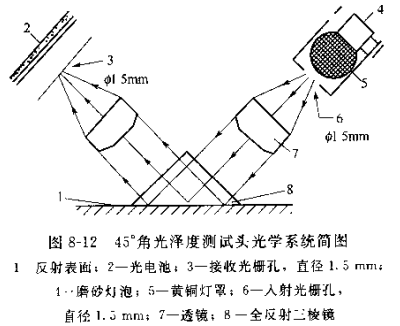

① The optical system of the instrument (see Figure 8-12). The light from a 3W frosted bulb powered by a stable power source shines on a grating with an aperture of 1.5 mm. The grating is at the focal point of the lens. The resulting parallel beam is projected onto the sample surface and reflected. The angle of incidence and angle of reflection are both 45° ± 0.5°. The reflected light is focused by the second lens to form an image of the incident light shed hole on the receiving grating hole, and the light beam is shot on the photocell.

The lens is an achromatic doublet cemented lens, and its relative aperture shall not exceed f/3.

The distance between the photocell and the receiving grating is sufficient, since the diameter of the light spot is about 19 mm.

The sample pressing plate is used for vacuum adsorption of the sample. When a plastic film with uniform thickness (such as 0.08 mm optical grade polyester film) is positioned with the suction plate, the image formed on the receiver window П and the image formed on the standard plate No measurable difference in position and size.

② Gloss standard. The standard surface is the hypotenuse of a totally internally reflective 45° right angle = prism. This surface is lined with anodized aluminum panels. The size of the prism is 25 mm × 25 mm × 35.3 mm, made of hard crown glass; the refractive index is in the range of 1.50~1.52. Absorbs 1.5%~2.0% of visible light within a distance of 25 rmm. The specular reflectance factor should be 80%~90%. The standard should be regularly calibrated by the superior metrology department.

③Black tube with black velvet lining.

3 Preparation of samples

① Sampling, processing and testing under standard conditions according to standard methods.

②Cut 10 pieces of 100mm×100mn test pieces from the extracted paper to avoid the defective parts. Keep clean. Do not use in contact with test surfaces.

4 test steps

① Turn on the power according to the instrument manual, after preheating, place the gloss standard plate on the measuring hole, and adjust the reading to the calibration value of the standard plate.

② Replace the black tube and adjust the reading of the instrument to zero, and then put on the standard plate to accurately adjust the reading of the instrument to the calibration value.

③Insert a piece of sample each time to read the gloss value, and measure the vertical and horizontal directions of each sample. Measure 10 times vertically and horizontally. The results are expressed as vertical and horizontal mean values and coefficients of variation. In order to ensure the test accuracy, during the long-term continuous test, the instrument should be calibrated with the standard plate regularly and re-calibrated once after the test is over.

5 accuracy

When testing a uniform sample with an instrument strictly in accordance with this method, the reproducibility of the test result is within 2 gloss units.