1 definition

Air permeability refers to the average air flow rate per unit area of the sample passing through per unit time and unit pressure difference, expressed in μm/Pa·s or ml/(m2·Pa·s).

2 instruments

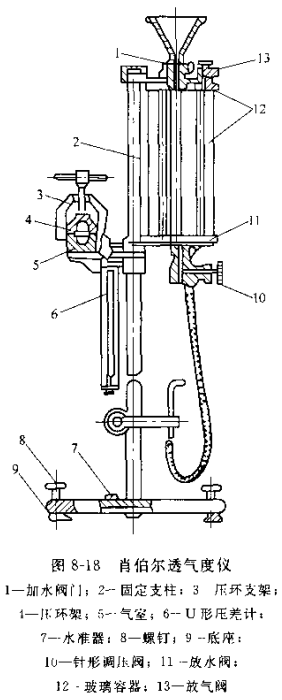

① Schober air permeability meter. Its structure is shown in Figure 8-18, which is composed of a glass container, a sample holding device, a pressure difference indicator, connecting pipes, etc.

The upper part of the glass container is equipped with an air release valve and a water filling valve with a funnel, and a water release valve and a needle pressure regulating valve are installed at the bottom of the container to control the flow of water. The sample clamping device consists of a pressure ring clamp, a pressure ring bracket and an air chamber. The pressure ring clamp is composed of upper and lower pressure rings, its inner diameter is 3.57 cm, and the test area is [10 ± 0.2) cm2. The ring clamp is fixed on the bracket. The air chamber is located under the ring clamp and is connected with the lower pressure ring. The air chamber has two connections. Use rubber tubes to connect with U-shaped differential pressure gauges respectively. The base of the instrument is equipped with a level and an adjusting screw to correct the level of the instrument.

② stopwatch. Can be accurate to 0.1 s.

③ Graduated cylinder.

3 working principle

Place the sample between the pressure ring and the air chamber, and the air chamber communicates with the U-shaped differential pressure gauge and the exhaust pipe inserted into the water surface of the glass container, open the drain valve and the needle valve, so that the water in the glass container flows into the measuring cylinder, and then A vacuum is formed on the upper part of the glass container, so that the air enters the air chamber through the sample, and then enters the vacuum part of the glass container through the exhaust pipe. The amount of air intake is equivalent to the flow rate of water, and the volume of water flowing out per unit time is measured. .is the air permeability of the sample.

4 Calibration of the instrument

To calibrate the airtightness of the instrument, adjust the instrument to the level, and then fill the glass container with water. A rubber gasket with a thickness of 0.5~1.0 mm and a diameter of 60 mm is clamped between the pressure rings instead of the sample, and the test is carried out according to the procedure for determining the air permeability. Adjust the pressure difference to 1.0 kPa (100 mmH2O) or 2.5 kPa (250 mmH2O), close the drain valve, and the pressure difference must not drop within half an hour. If there is air leakage, check the tightness of each joint and valve and adjust it.

5 Experiment preparation

①Sampling according to the standard method.

②Perform temperature and humidity treatment under standard temperature and humidity conditions.

③ Cut the sample into 10 test pieces of 60 mm × 100 mm, and mark the front and back sides.

④ Test under standard temperature and humidity conditions.

6 Test steps

①Close the water discharge valve and needle valve, open the water filling valve and air release valve, and fill the glass container with distilled water from the funnel.

② Place the sample to be tested between the pressure ring and the air chamber and clamp it tightly.

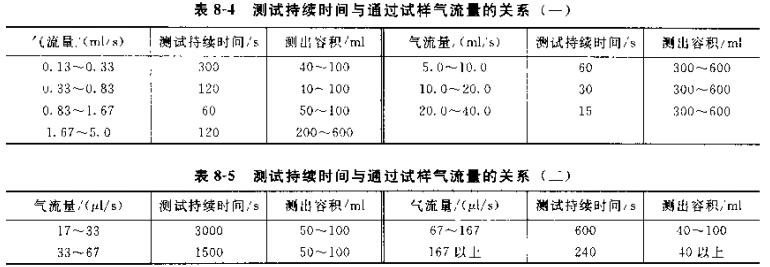

③Adjust the differential pressure to (1.00±0.01) kPa within 30 s. Refer to Table 8-4 to select an appropriate test duration, and immediately measure the air flow of the air-permeable sample. When choosing different test times, the reading deviation of the measurement results should not exceed 2.5% as the standard, and 5 positive and 5 negative sides should be used for the measurement.

④ When measuring high-density paper and cardboard, if the air flow through the sample is less than the minimum number in Table 84, the constant differential pressure shall be increased to (2.0 ± 0.01) kPa . According to the corresponding duration in Caizhou Table 8-5, then measure 5 fronts and 5 backs of the samples.

⑤Because air permeability has a good proportional relationship with constant pressure difference and measurement time, other measurement time can be selected if necessary, but it should be indicated in the report.

⑥ If the thickness of the sample is more than 0.3 mm, the edge outside the clamping area of the sample to be tested should be sealed to prevent the side air from affecting the results. Take extreme care in doing so so as not to disturb the testing area.

7 Calculation of results

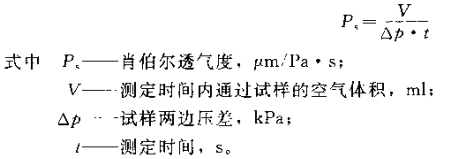

The air permeability of each test piece is calculated according to the following formula: