Rust removal before painting has always been a very hard and heavy labor. Although sandblasting has been used to replace manual derusting, the flying sand dust and rust dust and the roaring sound generated during the sandblasting and derusting process will cause serious environmental pollution. Workers who have been engaged in sandblasting and rust removal work for a long time are prone to silicosis. This requires reform in the derusting process. Rust-coating is one of the innovative methods of derusting process. The use of rust-coating can greatly improve work efficiency, reduce labor intensity of workers, improve operating conditions, and have a long service life. Low economic cost.

At present, there are three kinds of rusty coatings in CHINA: stable type, conversion type and penetrating type:

(1) Stable type

Its main function is to inhibit rust, that is, to maintain the status quo and prevent further expansion. Its composition is basically to add some high-efficiency corrosion inhibitors on the basis of iron red antirust primer. However, due to the limited amount of addition, only a very small amount of rust can be converted. Rust-stabilized coatings work on lightly rusted steel surfaces.

(2) Conversion type

It is mainly composed of substances that can transform rust (such as phosphoric acid, organic acids, potassium ferrous oxide, etc.), resins that can form paint films (such as polyvinyl butyral resin) and solvents (such as ethanol, butanol) and so on. . Its characteristic is that it can convert a certain amount of rust (the thickness of the rust layer is about 8o~100m). Although its rust removal ability is stronger than that of the stable rust coating, its solid content is less than the former, and the film formed The thickness is only about half of the stable coating film . It also has a disadvantage that it is necessary to separate the conversion liquid and the film-forming liquid into commercial tanks, and only temporarily mix them in a certain proportion before construction. The mixed paint has to be scrapped if it is not used up, resulting in waste.

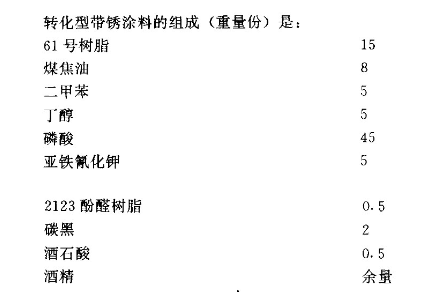

The composition (parts by weight) of conversion type band rust paint is:

(3) Penetration type

It does not use the chemical reaction to rust, but uses a solution with strong penetration ability to penetrate into the rust through physical osmosis, and surround the loose and porous rust, so as to isolate the rust from the external medium and achieve the purpose of stabilizing the rust. For the rust prevention of cut joints and spiral parts, it is most suitable to use penetrating rust coatings.