1 definition

The degree of sizing here specifically refers to the water resistance of paper or cardboard measured by the width of the ink line, expressed in mm as the maximum width (mm) of the line that does not spread or penetrate when the standard ink is used to line the line .

2 Instruments and Inks

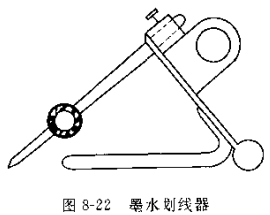

(1) The scriber of the instrument is shown in Figure 8-22

① straight line pen (duckbill pen). Use Fangyuan brand large pointed straight pen (Beijing Drawing Instrument Factory) and wide-headed straight pen.

②Standard pictures. Film printed with some standard width lines.

③A magnifying glass with a scale. The magnification is 10 times, and the scale division of measuring distance is 0.05mm.

(2) The standard ink is the standard sizing degree measurement ink produced by Beijing Ink Factory .

3 Sample collection, preparation and processing

① Carry out sampling according to the standard method.

② Carry out temperature and humidity treatment according to the standard method.

③ Cut the sample into 150mm×150mn square samples, and indicate the front and back sides.

4 test steps

① Adjust the width of the straight pen or scribe first according to the product standard requirements, and check whether the two ends of the straight pen or scribe are smooth and parallel, and then fill it with ink. Or double-sided offset printing paper 100g/m2) draw a straight line, and immediately dry it with filter paper or blotting paper, measure the line width with a standard picture or a magnifying glass until it is suitable.

② Spread the processed test piece on a glass plate, and inject ink into the straight line pen or scriber with adjusted width to make the ink content as high as possible.

③ Place the scriber on the paper, and draw a 10 cm long straight line at a speed of 10 c:n's along the direction at an angle of 45° to the longitudinal direction of the paper web, and refill ink for each line drawn. If you use straight line strokes directly, you should pay attention to keep the angle between the pen and the glass plate at 45°, and apply slight pressure to the sample. The line that can be drawn shall prevail. If the degree of sizing is greater than 1.5 mm, a wide-head straight pen should be used instead.

④ When drawing a line, the straight pen should stay at the start point and the end point of the line for 1 second respectively.

⑤ When drawing a line, generally draw a line based on the width specified in the product standard, and then adjust the width of the pen to draw several lines that are smaller than the standard width or larger than the standard width. And put the sample e flat on the test bench.

⑥ After air-drying under standard temperature and humidity, the degree of sizing is identified according to the "Paper to Ink Penetration and Diffusion Comparison Board". Find out the width of the maximum sizing degree, and pay attention to the two ends of the line! The within .5 cm is not used as the basis for identification.

⑦No less than 3 samples for each test, and the maximum width of all qualified front and back test results indicates the degree of sizing of paper or cardboard.