1 definition

(1) Ring compressive strength The maximum compressive force that the edge of the ring sample can withstand when it is compressed until it is crushed, expressed in kN/m.

(2 ) The ring compressive strength index is the ring compressive strength index divided by the average ring pressure. Expressed in N·m/g.

2 instruments

(1) The dimensional accuracy of the punching knife for sample cutting should reach (152.0±0.2) mm in length and <12.7+0.1) mm in width.

(2) The inner diameter of the sample holder is (49.30±0.05) mm, and the groove depth is (6.35±0.25) tmn. The parallel deviation between the bottom of the circular groove and the bottom surface of the sample holder is not more than 0.01 mm. The groove wall and the groove bottom are at right angles, and there must be no chamfers and arcs at the included angles. For this reason, it is better to divide the bottom of the tank and the wall of the tank into two pieces and add T. Then assemble them into one. The tangential direction of the groove wall is processed with a sample slot with a width not greater than 1.25 mm.

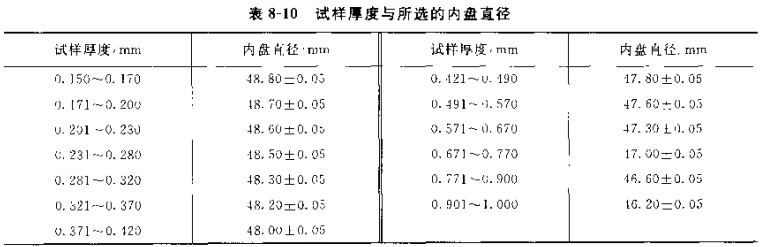

The sample holder is equipped with inner disks with different diameters, so that the sample gap generated by inserting the sample holder into the inner disk can adapt to samples of different thicknesses (see Table 8-10).

(3) Compressor

①Fixed platen electronic compressor. The instrument is equipped with upper and lower pressure plates with a size of not less than 100 mm×100 mm. The plate surface is flat and meets the following requirements: the parallelism deviation between the two plates is not greater than 1:2000; the lateral shaking of the two plates does not exceed 0.05 mm.

During the test, one pressing plate is driven by a motor to press against the other pressing plate, and the operating speed of the pressing plate is (12.5±2.5) mm/nin. The force measurement accuracy of the instrument is 1% of the indicated value.

② Bending beam compression instrument. The requirements for the upper and lower pressure plates are the same as those of the fixed plate electronic compression instrument. During the test, the speed of the upper plate pressing down the lower plate is <12.5±2.5) tmm/min. The loading speed is (110±23).V's. Instrument The scope of application is 20%~~80% of the maximum range of the spring plate. The force measurement accuracy of the instrument is 1% of the indicated value.

3 principles

(1) Electronic compressor The electronic compressor is a mechatronics test device. During the test, the lower platen is affected by the transmission mechanism. Rise at a constant speed at a specified speed, and apply gradually increasing pressure to the sample. The force sensor converts the pressure on the sample into a voltage and inputs it into the circuit. Displayed after circuit processing.

(2) Curved beam bed shrinkage Tester, which is designed according to Hooke's theorem and the bending deformation theory of beams.

During the measurement, the sample is placed in the sample between the upper and lower platens. Start the instrument and make the upper platen drop at a constant speed. when touching the sample. The pressure on the upper platen is transmitted to the spring plate through the sample and the lower platen to deform it. The degree of deformation is reflected in meters by the thousandths installed under the spring plate. The Shanghai Medical Board continued to decline. The pressure on the sample gradually increases. The deformation of the spring plate also increases thereupon. When the force on the sample reaches the limit value, that is, when it is pressed down, the value indicated by the thousandth length is the maximum value of the deformation of the spring plate. The force that deforms the spring is the force that the specimen bears. Then, through the pressure-deformation diagram. Li gives the compression force value corresponding to a certain amount of deformation. That is the ring E strength of the test.

4 Calibration of the instrument

(1) Calibration of the parallelism of the pressure plate, measure the distance between the four corners of the upper and lower pressure plates with the inner diameter dial gauge. The maximum and minimum divided by the side length of the pressure plate is the parallelism deviation between the two plates. Should not be greater than l :2000 .

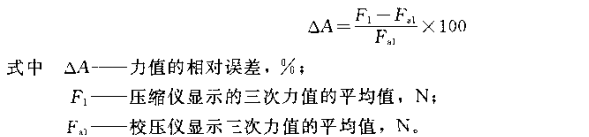

(2) Calibration of the accuracy of the compression instrument: use an electronic calibrator with an accuracy of 1/1000 to measure on the instrument. Place the sensor (with seat) of the pressure gauge between the upper and lower pressure plates of the pressure gauge. Drive the pressure plate to directly apply pressure to the sensor, observe the pressure calibration instrument head, and stop applying pressure when the predetermined value is reached. Read the indication values of the compression gauge and the pressure calibration gauge respectively, and then find out the corresponding force value. Select five test points evenly within the range of 20%~80% of the full scale of the compression instrument, repeat the test three times for each point according to the process, and calculate the error AA based on the force value of the pressure calibrator. AA does not exceed ±1%.

5 test preparation

① Carry out sampling according to the standard method.

②According to the standard method for temperature and humidity treatment.

③ Use a special punching knife to cut into a sample with a width of 12.1 mm and a length of 152 mm. At least 10 slices shall be cut vertically and horizontally, and no burrs or other defects affecting the measurement results shall be allowed on the edges of the slices. The sample whose long side is perpendicular to the longitudinal direction is used to measure the longitudinal ring compressive strength, and the sample whose long side is parallel to the longitudinal direction is used to measure the transverse ring compressive strength. The error of the parallelism between the two sides of the sample is not more than 0.015 mm.

④ Tested under standard temperature and humidity conditions.

6 tests

① Measure the thickness of the sample, and select the inner plate of the sample holder according to the thickness of the sample. Carefully insert the specimen into the specimen holder, making sure to bottom it out.

②Place the sample seat in the middle of the lower platen, and at the same time, the opening of the sample ring faces the operator. Then start the instrument and press the sample until it collapses. The fixed plate electronic instrument directly reads the pressure value, accurate to 1N. The bent beam instrument reads the maximum deformation of the spring plate, with an accuracy of 0.01 mm, and then finds the force required to crush the sample from the stress-strain curve of the spring plate, with an accuracy of 1 N.

③Repeat at least 10 samples in each direction vertically and horizontally. At the same time, in each direction, 5 samples should face outward, and 5 samples should be bent outward to form a ring test.

7 Calculation of results

①Calculate the average value F(N) of vertical and horizontal forces respectively.

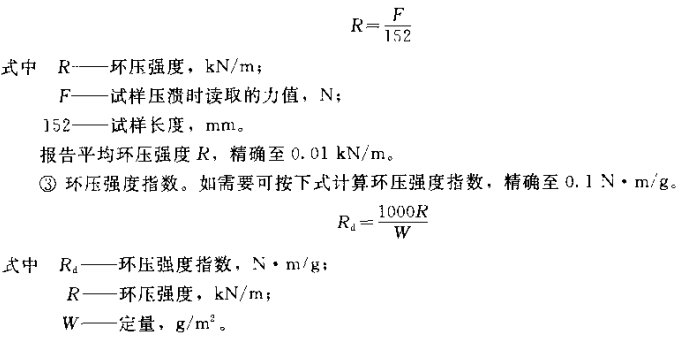

②Ring pressure strength. Calculate the ring compressive strength according to the formula;