Pigments and extender pigments used in color paints should be evenly dispersed in the paint with tiny particles. When coated into a thin film with a thickness of tens microns, the surface of the coating film should be smooth and free of pigments, etc. Granular objects appear. In order to express the degree of dispersion of pigments in paint, the test item of fineness has been formulated. In addition to being used to check paints, varnishes are now sometimes tested for fineness to check whether they contain minute mechanical impurities. Fineness is also called grinding fineness.

The detection of fineness is to spread the paint into films with different thicknesses, and observe at what thickness the pigment particles appear, which is called the fineness of the paint. The testing instruments used are generally called Fineness Meters, and the test results are expressed in microns express. The actual measured value is the size of the larger solid particles in the coating, indicating the degree of coarse particles present. It should be pointed out that these coarse particles are not the size of individual pigments or extender pigment particles, but the size of agglomerates that exist . The particle size of a single pigment or extender pigment is generally a few tenths of a micron, and once aggregated, it can be as large as tens of microns or even hundreds of microns. The color paint can only disperse the large pigment agglomerates into small pigment agglomerates during the grinding process . At present, the most precise grinding process cannot disperse the agglomerates into individual particles, but only disperses the agglomerates to a particle size as small as about 10 μm.

Grinding fineness is one of the important internal qualities of paint, which has a great influence on the film quality, gloss and durability of the paint film, and the storage stability of the paint. The color paint with fine particles and good dispersion, the pigment can be wetted better, and the space between the particles is less filled by paint, so the paint film produced in this way is uniform in color, smooth in surface and good in gloss, and the paint is stable during storage. During the process, the pigments are not prone to precipitation and agglomeration, which improves the storage stability.

Of course, the finer the finer, the better. Too fine not only prolongs the grinding time and occupies the grinding equipment, but also the adhesion of the paint film, which needs to be treated differently according to the variety and application. Generally speaking, the fineness required for primers and topcoats is different. In CHINA, the fineness of primers is currently not greater than 50 μm or 60 μm, and the fineness of alkyd, amino and other decorative topcoats is not greater than 20 μm. Varieties are required to be below 15μm.

The measurement of grinding fineness is currently basically using scraper Fineness Meters in all countries in the world. The test principle is exactly the same, and there are differences only in the size, material and reading unit of the scraper. The scraper fineness gauge is a polished flat plate with a wedge-shaped groove . There are scale marks on the edge of the groove to indicate the depth of the groove; there is also a scraper with both edges polished. When using, drop the sample into the deepest part of the groove, then touch the flat plate vertically with a scraper, pull the paint across the entire length , and immediately observe the uniform appearance of the particles in the groove with the light at an angle of 30° The position is the fineness of the sample. This method is easy to operate, easy to clean, and fast in test speed, and is suitable for on-site production control. However, it should be noted that the consistency of the sample should meet the requirements of the product standard to avoid errors during the test.

At present, the scraper Fineness Meter tends to adopt the double-slot type, so that the tested sample and the standard sample can be compared at the same time, or in one test, two parallel test data of the tested sample can be obtained at the same time. In terms of reading judgment, some standards suggest to use the line method to judge the fineness of the paint. Compared with the particle density method, the line method fineness value is about half to the less demanding fineness. Primer, boat bottom paint, anti-fouling paint and anti-skid paint with thicker particles and anti-skid ingredients added due to special needs .

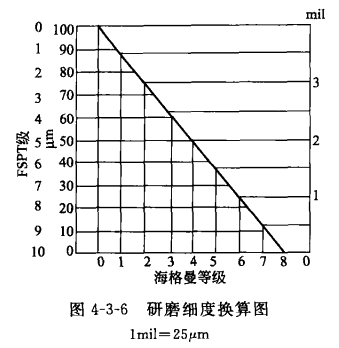

The specifications of the general Fineness Meter are different from country to country. The Fineness Meter stipulated in the national standard GB/T 1724-1979 (1989) " Determination of " has three specifications: 0~150μm, 0~100μm and 0~50μm . CHINA's GB 6753.1-2007 "Determination of Grinding Fineness of Paints, Varnishes and Printing Inks", which is equivalent to the ISO standard in CHINA, is divided into four specifications: 100 μm, 50 μm, 25 μm and 15 μm. American ASTM D1210 (1979) stipulates that the groove length is 100 μm, and the classification is expressed by Hegman level, mil and FSPT specification of the Federation of Paint Technology. The Japanese JIS standard is 100 μm. The conversion relationship between American Hegman grade, mil, FSPT grade and μm is shown in Figure 4-3-6.