The materials used to manufacture various products include steel, non-ferrous metals, wood, plastics (including composite materials), leather, rubber, fabric, paper, glass, ceramics, etc. Due to the differences in the surface physical and chemical properties of various materials, the adaptability to coatings is different, and the construction requirements are also different. For example, most paints have strong adhesion to steel surfaces, but poor adhesion on light metal surfaces such as aluminum and zinc, and can only be coated with zinc yellow and strontium yellow primers or pre-coated phosphating primers to improve adhesion.

For wood, due to the porosity, the coating is easy to penetrate and be absorbed, lose gloss, and a pre-applied sealer is required. For some plastic surfaces, it is easy to be swelled by the solvent in the paint, or even dissolved and eroded, which will also cause the paint film to lose its gloss. However, the problem with most plastics is that the adhesion is too poor, and special plastic primers or other measures need to be used.

Due to the difference in corrosion mechanism and corrosion resistance of different materials, the designed coating system is also different. It is not possible to copy the coating system on the steel surface and transfer it to the cast iron or light metal or even the plastic surface. For example, the coating system on the surface of steel is generally primer + topcoat (+ varnish); while the oxide film on the surface of aluminum metal has excellent protection, it only needs to be painted with a varnish after coloring. The main purpose of plastic is to prevent photoaging, and only need to apply a colored topcoat according to the color plan.

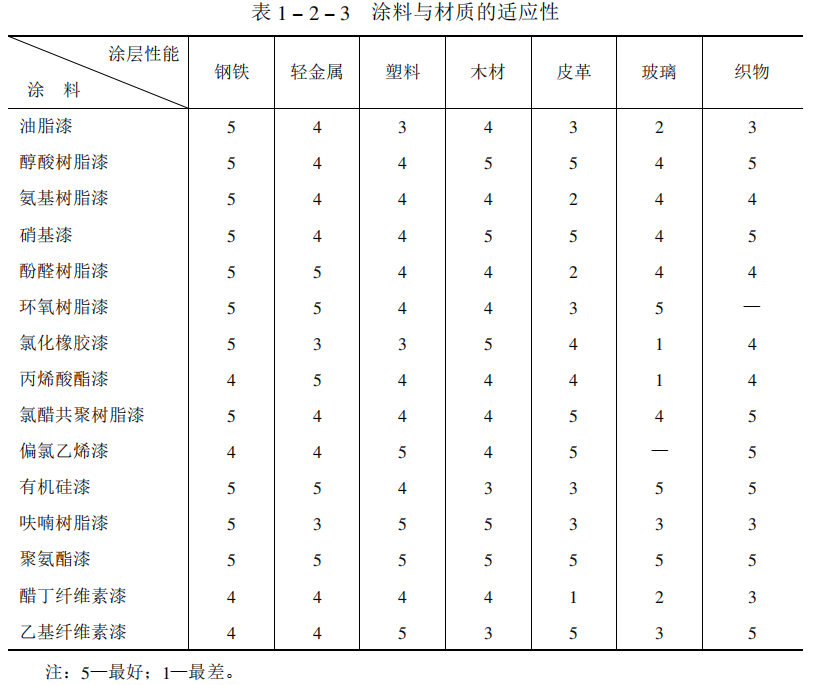

See the table for the adaptability of various coatings and different materials.