According to the parameters such as the thickness, density, non-volatile content of paint and paint utilization rate of each layer of paint film, the paint consumption per unit area of each layer of paint film can be obtained according to the following formula:

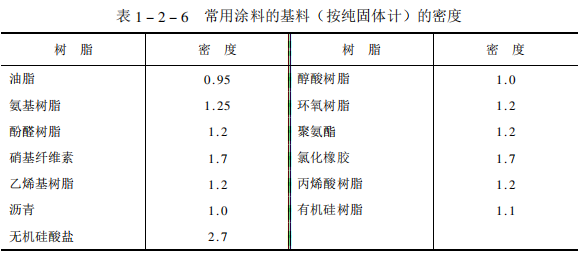

If the coating is varnish, the coating film density can take the approximate value of resin density listed in Table 1-2-6.

Example 1 How much paint per unit area is required for electrostatic spraying of amino varnish?

Solution: When electrostatic spraying, the paint utilization rate e=80%, the solid content of the original paint of amino varnish is generally 45%, the thickness of the coating film sprayed once is 25μm, and the density of amino resin ρF=1.25g/cm³,

Then qe= 25×1.25/ (45%×80%)|= 86.8 (g/m2)

For color paints, the coating film density can be calculated from the pigment-base ratio, resin and pigment density:

ρF = (1+PB)/(1/ ρB +PB/ ρp)

Example 2 When 8912 cathodic electrophoretic paint is used for electrophoretic painting, what is the required amount of paint per unit area?

Solution: The paint utilization rate e=95% during electrophoretic painting. 8912 electrophoretic paint has the following indicators: the solid content of the original paint is 50%, PB = 03, and the film thickness is 20 μm.

Cathodic electrophoretic paint is epoxy resin, ρB = 1.2 from Table 1-2-6. The primer is mainly carbon black and inorganic pigments and fillers, with an average of ρB= 1.8,

Then ρF= (1+0.3)/(1/1.2+0.3/1.8) =1.3

Then qc= (20 × 1.3)/(50% × 95%) =54.7 (g/m2)

If the pigment-base ratio (PB) and pigment volume concentration (PVC) are known at the same time, the coating film density can be obtained as follows:

ρF= (PVC)x(1+ 1/PB)×ρP

For each product produced by paint manufacturers, there is generally a parameter of volume solid percentage, then