1. Coating composition

Anodic electrophoretic paint is a new variety of paint that was put into industrial application abroad in the 1960s. The film-forming substance is an anionic polymer with a carboxyl group, which is neutralized with an alkaline substance to impart ionicity, solubilized and dispersed in water. Neutralizers are commonly used organic amines and inorganic bases, such as ethanolamine, triethanolamine, triethylamine, KOH, etc.

This kind of resin forms a stable water dispersion system with pigments (fillers) and various additives. Under the action of a direct current electric field, the negatively charged resin wraps the pigment, swims to the anode together and deposits on the surface of the anode. Therefore, this type of coating is called anodic electrophoretic coating.

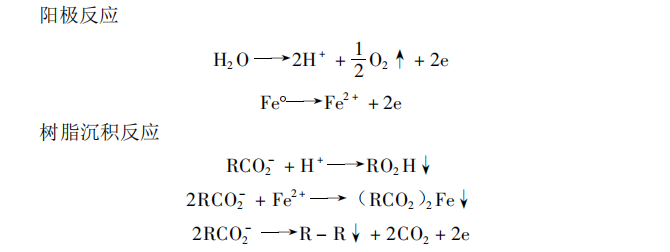

Electrophoretic painting undergoes four processes of electrophoresis, electrolysis, electrodeposition, and electroosmosis at the same time, forming a dense coating film with extremely low moisture content and relatively high resistance on the metal surface. The electrochemical reaction of the deposition process is expressed as follows:

2. Characteristics of anodic electrophoretic coatings

(1) The coating film is uniform, smooth and flat, and has strong adhesion; a relatively uniform coating film can be coated on edges, weld seams, and inner and outer surfaces of box-shaped bodies, and the corrosion resistance is significantly improved.

(2) The solid content of the bath liquid is low, the amount of adhesion on the surface is small, and the paint utilization rate is as high as 90%~95%.

(3) Electrophoretic coating uses water as a dispersion medium, which saves resources, reduces air pollution, eliminates the risk of fire, and improves the working environment.

(4) High coating efficiency, especially suitable for mass production line automation.

(5) The electrophoretic coating equipment is complicated and the investment cost is large.

(6) Wastewater is produced and needs to be treated.

(7) The dissolution of metal ions on the surface of the workpiece deepens the color of the coating film; the oxygen generated by electrolysis easily oxidizes the resin, which affects the corrosion resistance and decorative properties of the anodic electrophoretic coating film, and is not suitable for light-colored paints.