The air spraying method, also known as air spraying and ordinary spraying, relies on the airflow of compressed air to form a negative pressure at the nozzle to take the paint out of the paint storage tank and atomize the paint into a mist. With the help of the airflow, the paint A method of reaching the surface of the object to be coated. The air spraying equipment is simple, easy to operate, easy to maintain, its coating efficiency is high, the workability is good, the paint film obtained is uniform and beautiful, and it can coat 150~200m2 per hour (about 8~10 times of brush coating), suitable for spraying General paint. The disadvantages of air spraying are: the paint needs to be prepared according to the proportion before spraying, and the appropriate viscosity is adjusted. When spraying, a considerable part of the paint is lost with the diffusion of the air; the film is thin, and it takes multiple spraying operations to reach the specified film thickness requirements. The permeability and adhesion of paint are generally worse than that of brushing; the paint and solvent diffused in the air are harmful to the human body and the environment; in the case of poor ventilation, the vapor of the solvent reaches a certain level, which may cause explosion and fire. With the development of marine and heavy-duty anti-corrosion coatings in the direction of high solids, air spraying is rarely used in this field.

(1) Equipment and tools for air spraying method

The air spray unit includes:

(1) Spray gun: form the paint into mist and spray it on the surface of the object to be coated;

(2) Compressed air supply and purification system (Air Compressor): supply clean, dry, oil-free compressed air;

(3) Paint delivery device: store paint and supply paint continuously;

(4) Rubber hose: transport compressed air;

(5) Paint spray room: install ventilation safety equipment, the indoor temperature is 18~30 ℃, and the relative humidity is less than 70%.

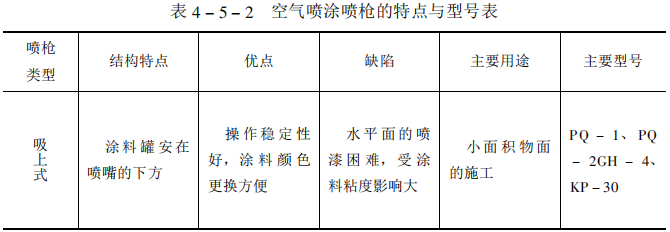

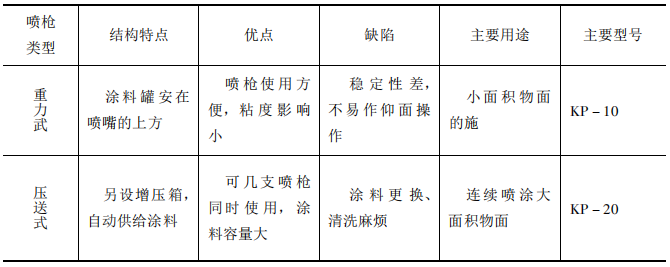

The Spray Gun is the main tool of the air spray method, and its type, structure and operation greatly affect the coating quality. A Spray Gun is a tool that atomizes and sprays the paint onto the surface of the substrate after mixing the paint with compressed air. There are many types of Spray Guns, which are classified according to the way the paint is supplied. There are mainly three types: suction type, gravity type and pressure-feed type. Figure 4-5-1 shows the schematic diagrams of the three types of Spray Guns. Table 4-5-2 shows the characteristics and models of air Spray Guns.

According to the performance characteristics of various Spray Guns in the above table and the requirements of the coating object, according to the nozzle diameter and air consumption, etc., reasonably select the type and specification of the Spray Gun. When choosing a Spray Gun, you should also consider the size and weight of the Spray Gun itself, the amount of paint, loss, etc. The larger the diameter of the nozzle and the greater the pressure, the greater the amount of paint sprayed; the higher the viscosity of the paint, the less the amount of paint sprayed. For large-area painting, Spray Guns with continuous paint supply system should be used, and flat or slightly larger-aperture nozzles should be used; for small-area painting, Spray Guns with intermittent paint supply and small-caliber nozzles can be used. A circular nozzle with a diameter of 0.5 mm is used for repairing. The spraying pressure can be adjusted according to the size of the nozzle and the nature of the paint. If the air pressure is too high, although the atomization is fine, the paint will scatter a lot and the loss will be great. Conversely, if the pressure is insufficient, the spray will become thicker, resulting in defects such as orange peel and pinholes. Generally, higher pressure is used for high-viscosity coatings, such as putty spraying, the pressure is generally 0.34 MPa; the pressure of high-viscosity coatings is 0.25-0.3 MPa, and the pressure of low-viscosity coatings is 0.1-0.15 MPa.

(2) Construction method of air spraying

The quality of painting construction mainly depends on the viscosity of the paint, the working pressure, the distance from the nozzle writing surface, and the technical proficiency of the operator. In order to obtain a smooth, even and uniform coating, it is necessary to master the correct operation method when painting.

(1) The nozzle diameter for putty is 3.5~4.5mm; the nozzle diameter for low viscosity paint is 1~1.5mm; the nozzle diameter for high viscosity paint is 2~3mm. The relationship between the spraying object and the nozzle: the diameter of the nozzle for spraying small areas is 1~1.5mm; the diameter of nozzles for spraying large areas is 2.5~3mm; the diameter of nozzles for spraying various patterns and characters is 0.2~1.2mm.

The distance between the Spray Gun and the surface to be coated has a great influence on the quality of the paint film. If the distance is too close, the paint layer will thicken, causing flow and orange peel; if the distance is too far, the paint film will become thinner, the paint will lose more, the paint film will fall off easily, the paint film will be uneven, and the gloss will be greatly reduced in severe cases. Generally, the spray distance is 200-300mm, the small-caliber Spray Gun is 150-250mm, and the spray distance of the large-caliber Spray Gun.

(2) Gently hold the handle of the gun with the ring finger and little finger, hook the trigger with the index finger and middle finger, and clamp the handle in the tiger's mouth; when spraying, follow the Spray Gun with your eyes, and pay attention to the formation of the coating film and the landing point of the nozzle at any time. The spraying distance and vertical angle between the Spray Gun and the object surface are controlled by the body. The movement of the Spray Gun also needs to use the body to assist the movement of the arms. The wrist cannot be moved, but the wrist must be flexible.

(3) When the Spray Gun is running, the Spray Gun should be kept at right angles to the surface to be coated and run in parallel. The moving speed of the Spray Gun is generally adjusted within 30 ~ 60cm/s, and it is required to keep moving at a uniform speed as much as possible. The distance between the Spray Gun and the surface to be coated is between 20~30cm.

(4) During operation, the edge of each spraying range should be repeated 1/3 ~ 1/2 on the edge of the previously sprayed range, and the width of the border should be consistent. If the width of the gap is variable, the film thickness will be uneven, and streaks and marks may occur.

(5) In order to obtain a more uniform coating and better anti-corrosion effect, when spraying the second coat, it should cross the previous paint film vertically and horizontally, that is, if the first coat is sprayed horizontally, the second coat should be sprayed vertically spraying.

(6) When spraying each time, the Spray Gun trigger should be turned on when the Spray Gun is moving, and the Spray Gun trigger should also be turned off when the Spray Gun is moving, so as to avoid excessive accumulation of paint on the surface of the workpiece and sagging.

(7) After spraying, the excess recyclable paint should be poured back into the original paint bucket, and then the Spray Gun should be cleaned, and no residual paint in the Spray Gun is allowed. When cleaning the Spray Gun, the corresponding thinner of the paint can be poured into the paint can, and the trigger is pulled, and the solvent is sprayed out from the nozzle of the Spray Gun, so that the paint pipeline can be cleaned. Then shut off the compressed air, remove the Spray Gun and wipe it clean with solvent. Clean the air cap, nozzle, and gun body carefully with a brush with solvent. When the air hole is blocked, it needs to be dredged with a cork needle. Check the tightness of the needle valve gasket and air valve gasket, paint on the sealing ring, and hang it.

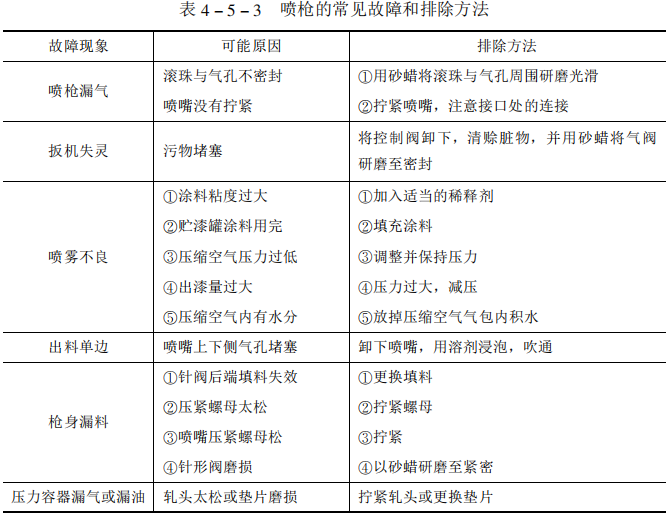

(8) See Table 4-5-3 for common faults and troubleshooting methods of Spray Guns.