Classified according to the airflow organization form of the spray booth, there are two main types: side draft type and bottom draft type, and its functions are shown in Figure 5-5-1 and Figure 5-5-2.

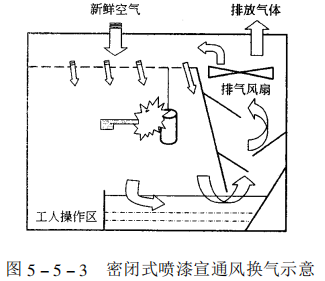

The side draft spray booth uses the kinetic energy of the compressed air during painting to make the air flow around the operator rush to the painted workpiece, and then it is discharged after being treated by the paint mist removal device. However, for large workpieces, it is difficult to maintain sufficient airflow from all directions , and the lateral airflow structure is not easy to form, so a bottom-drawing spray booth can be used, and its function is shown in Figure 5-5-3.

Bottom draft type paint spraying room is for the top micro-hole to send maple, and the bottom grille for ventilation, and the operating area with fresh air is formed through the airflow organization. For large-scale closed spray booths, the air flow organization can adopt the ventilation method as shown in , that is, air is supplied from the top and exhausted from the bottom. Part of the fresh air sent in is discharged into the atmosphere, and the other part can be recycled through the spray booth. . The air exchange in the spray booth adopts the blow-suction type, so that the airflow is in the shape of stellar flow; the polluted air containing organic solvent vapor is distinguished from the fresh air.

The safety and anti-virus of the spray booth requires sufficient air volume. Therefore, the wind speed should be correctly selected and effectively controlled. The control wind speed at the operation port of the side draft spray booth is preferably 0.7~0.8m/s. If it is a spray booth with bottom draft, the control wind speed at the top air supply port is preferably 0.3~0.5m/s, and the maximum should not exceed 0.5m/s.

The air volume of the exhaust air at the bottom of the spray booth should be slightly smaller than the air supply volume, so as to maintain a slight positive pressure in the room. It also makes it difficult for the surrounding dusty air to enter. In particular, it should be pointed out that the controlled wind speed of a large spray booth should not be too high. If the selected controlled wind speed is too high, not only the air volume will be large, but also the resistance of the microporous filter at the top of the spray booth will increase Increased energy consumption and increased noise bring difficulties to the noise . The noise control of large air volume and high pressure fans is not only technically complex, but also costly .