The paint mist removal device in the spray booth is a key component of the spray booth, which directly affects the paint mist purification effect, and the paint mist removal efficiency, which shows the purification effect, is one of the main evaluation indicators for the performance of the spray booth.

There are two types of paint mist removal devices: dry type and wet type.

There are two types of dry paint mist removal devices: baffle plate and filter screen, which can also be used together. With a reasonably designed and effective dry paint mist removal device, the efficiency of collecting paint mist can reach more than 90%.

1. Dry paint mist removal device

Dry paint mist removal devices use baffles or filters to trap paint mist without using water. For example, a certain type of dry spray booth imported from Japan uses filter paper to capture paint mist. This filter paper is patented by the United States. It has high tensile strength, high capture efficiency, easy assembly and disassembly, and convenient use. Use it for a period of time , take it out and shake the dry paint, it can be used again, and it can be used continuously for a long time. According to reports, it has been installed used for nearly ten years, and it still performs well. In short, the dry spray booth has a simple structure, low air volume and wind pressure; under the same purification effect, the dry spray booth takes away less paint mist, so the paint loss is small and the coating efficiency is high. Since the dry spray booth does not use water, no waste water is generated, and no water treatment is required, the operating cost is relatively low. The disadvantage is that the interior and baffles are easily polluted by paint mist, and need to be cleaned frequently, which is labor-intensive. At the same time, the filter screen is a waste crystal, which consumes a lot and needs to be replaced frequently . Due to serious pollution, it may also cause natural pollution under certain conditions; therefore, dry spray booths are more suitable for single-piece small-batch workpiece painting with high coating efficiency. Large volume spray painting is not suitable.

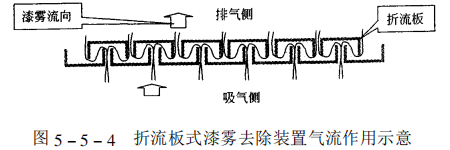

The baffle type paint mist removal device is composed of a plurality of bow-shaped plates that are engaged with each other. The bow-shaped plates can be made of ordinary steel plates with a thickness of 1.5~2.0mm. For frequent disassembly and repair, the structure is required to have the characteristics of easy . In order to improve the efficiency of adhering paint mist, it is necessary to cover the baffle with special fiber paper and easily remove it from the baffle to remove the paint mist adhering to the special fiber paper.

The baffle type paint mist removal device is installed in front of the exhaust port of the spray booth. The airflow containing paint mist flows through the baffle plate, and the airflow is twisted several times to adhere the viscous paint to the board. The action process of the baffle is shown in Figure 5-5-4.

The air flow rate of the baffle type paint mist removal device is preferably 5-8m/s, and the gap width is usually 30mm. Under this working condition, the resistance loss per unit length (per meter) is 60-120Pa.

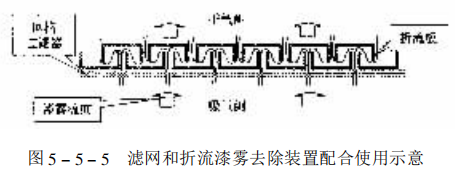

Another kind of paint mist removal device is fixed on the frame with a paper fiber filter. Due to the large , it can capture both viscous and viscous paint mist and paint particles. However, when the working time is long, the mesh is easy to be blocked, and a new filter must be replaced. In recent years, CHINA's shipbuilding industry and construction machinery industry have introduced foreign- made filter paper, and the removal efficiency of paint mist can reach more than 90%. When regenerating, just shake the paint mist on the filter paper to shake off the adhered paint mist and paint particles, and then it can be used again, and still maintain a good paint mist removal efficiency.

The filter paint mist removal device is often used in conjunction with the baffle paint mist removal device, as shown in Figure 5-5-5.

The air flow rate of the filter paint mist removal device is preferably about 2m/s, and the resistance loss per meter is relatively large. It should be 100~160Pao for rough calculation

Dry spray booths have a series of products in industrially developed countries abroad. They are generally used for spraying . They are also matched with pretreatment production lines. They can be used immediately after the shot blasting room . spray paint.

There are fewer specifications for domestic dry spray booths to be put on the market as commodities. The internal size of the dry spray booth for medium and small workpieces is 1.5mx 1.1mx 1.2m, and the internal size is 4.7mx 1.8mx 1.2m. The air volume range is 3000~15000ms/h. more common.

As for the dry spray booths made by factories for their own use, there are many kinds, and they are mostly used in the bus manufacturing industry.

2. Wet spray booth

Wet spray booths mainly use water to deal with paint mist, and also use oil to deal with paint mist. Using water as the medium is far more extensive than using oil. Because it has no fire hazard, it is safe and reliable. Especially in mass production, wet spray booths are more commonly used.

All wet spray booths with water as the medium have waste water discharge. It is difficult to store the water that absorbs paint mist at room temperature for a long time . Especially in summer, the water quality is prone to deterioration, and a waste water treatment device is required.

Wet spray booths that use water as the medium to control paint mist, due to the use of different paint mist removal devices, are different in terms of structure, application effect and applicability. Now there are four different types Curtain type, pumpless type, Venturi tube type and water cyclone type are introduced as follows.

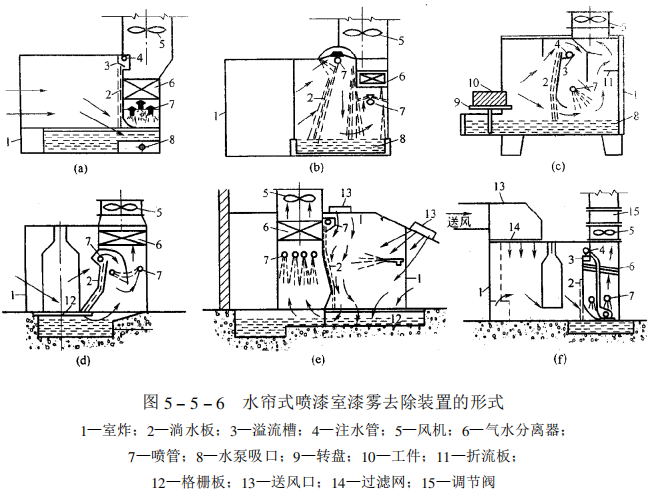

(1) Water curtain spray booth . The water curtain spray booth is a . The workpiece is sprayed by the paint mist sprayed by the Spray Gun in the chamber of the spray booth, and the operator is located in front of the chamber to operate. The body of this type of spray booth has different structural forms .

For small and medium-sized workpieces produced in single pieces and small batches, the body of the spray booth is made into a closed structure, and a general-purpose rotary workbench is installed indoors .

For medium and small workpieces produced in batches, because of the suspension conveyor, it is necessary to open doors on the two opposite walls of the chamber for the workpiece and the conveyor chain to transfer. In addition, in order to enable the workpiece to rotate when passing through the spray booth , it is necessary to install a pinion on the workpiece spreader, and set a rack on the chamber body for the workpiece to realize the rotation during the transmission .

For large and medium workpieces produced in batches, since the ground conveyor is used, the two walls of the chamber must be passed by the ground conveyor and large and medium workpieces, so the chamber is often a semi-open structure.

Therefore, there are a variety of variant series products for water curtain spray booths, which are available for selection, and such series products are available in the domestic market.

The main components of the water curtain spray booth are: room body, water curtain paint mist removal device, spray device , water pump and water pump accessories, gas-water separator, fan and air pipe accessories, and lighting devices.

There are several forms of paint mist removal devices for water curtain spray booths due to the different forms of water curtains, as shown in Figure 5-5-6.

In Figure 5-5-6 (a), (c) the two forms of water curtains are formed by overflow; the two are formed by spraying; the two forms of water in e and f The curtain is equipped with a ventilation system.

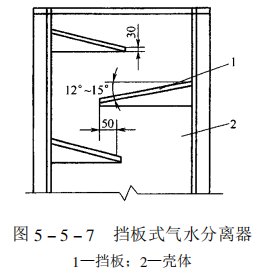

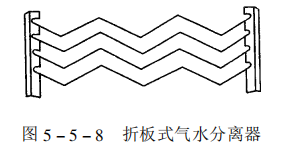

The function of the air-water separator is to prevent the water droplets of the washing paint mist from being sucked into the fan. The commonly used structural forms are baffle type and folding plate type, as shown in Figure 5-5-7 and Figure 5-5-8.

The baffle is inclined in the horizontal direction, and the included angle is preferably 12°~16°, and the downward inclination promotes the separation of air and water. The gap between the baffles can be folded according to the flow rate of the exhausted air. It should be bent from top to bottom, and the bending angle should be 30°~45 ° ; the distance between the baffles is about 30mm, and the height is 250mm .

The dripping board is a key component of the water curtain spray booth, which requires strict straightness and strict verticality during installation. The material of the dripping board is mostly made of stainless steel, and its width is the same as that of the spray booth. The thickness of the water film on the running water board is about 3~5mm, which requires a certain amount of water, and the mass ratio of the water amount to the air amount is 1.2~1.4.

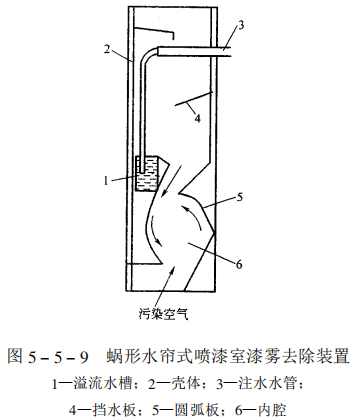

In order to improve the purification efficiency of the paint mist removal device in the water curtain spray booth, the dripping plate is improved into a snail shape , which is called the snail-shaped water curtain paint mist removal device, as shown in Figure 5-5-9.

The snail-shaped paint mist removal device is composed of two circular arc plates, which are approximately snail-shaped, and the air containing paint mist enters along the tangential direction. Due to the guiding effect of the snail-shaped plate and the long-term contact with the water, under the action of centrifugal force, The paint particles are separated from the water, adsorbed by the water, and flow into the Water Tank along the arc surface of the volute. Due to the above effects, the paint mist removal efficiency is mostly above 90%, but the pressure loss is relatively large, so a fan with a higher wind pressure must be selected.

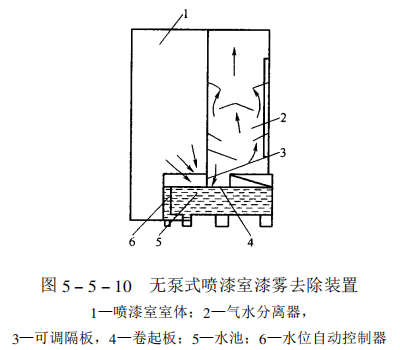

(2) No pump spray booth . The pumpless spray booth is a wet spray booth with water as the treatment medium, which relies on water to absorb paint mist in the air. But without water pump and water pipe type spraying device, but only by blower fan , Water Tank, baffle plate, roll-up plate and water separator etc. to form.

The working process of the paint mist removal device in the pumpless spray booth is completed by 5 steps, namely, collecting, spraying, washing, dehydration and drainage. The working principle of paint mist removal is shown in Figure 5-5-10.

It can be seen from the figure that there is an adjustable gap between the adjustable partition 3 and the roll-up plate 4, about 10-20mm. The air containing paint mist passes through this gap at high speed, and the throttling is accelerated. Under the guidance of the rolled-up plate, the airflow forms a swirl along the rolled-up plate immersed in water. The swirl atomizes the water and mixes with the swirl to form The high-speed airflow containing paint mist and water flow (or water mist) changes the flow direction several times in the water along the arc surface of the roll-up plate 4, then passes through the air-water separator 2, dehydrates after several deflections, and discharges into the atmosphere .

From the above working principle, it can be seen that the larger the air volume of the spray booth, the greater the wind speed entering the gap. When the impact about 15m/s, the purification efficiency of the paint mist removal device will reach more than 95%, and the resistance will be 1200~ 1400Pao As the impact wind speed increases, both efficiency and resistance will increase.

In order to improve the purification efficiency of the paint mist removal device in the pumpless spray booth, there are several measures as follows.

① The gap through which the impact air flow flows should form an S-shape, and its curved surface is required to be as smooth and neat as possible to reduce the loss of resistance .

② When the air containing paint mist flows through the guide plate, it should have a longer residence time as possible.

③须保证漆雾与水槽内有足够的水量。

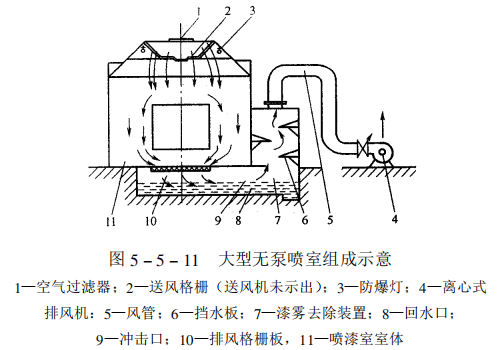

中小型无泵式喷漆室有国产系列产品,其操作空间容积对于小件,多为2500mmx1250mm有1100mm对于中型件,其操作间尺寸为3500mmx1250mmx1300mm,其最大空间尺寸预留为4000mmx 250mmx1300mm对于大件,则需要采用密闭式室体的无泵喷漆室,如图5-5-11所示。

过滤后的干净新鲜空气,经送风机(图5-5-11)压送从上部进人喷漆室,将喷漆漆雾扩散造成的废气下压,不使漆雾在喷漆室的上部区域徘徊停留,并通过送风系统不断补充新鲜空

以改善操作区劳动条件。随后,通过排风机的抽吸作用,使漆雾迅速通过排风格栅,经下部间隙形成的旋风气流冲击,使水形成水滴、水露,并使水与漆雾空气混合接触,完成无泵式喷漆室的漆雾去除过程。

上述密闭式室体的无泵式喷漆室可用来调节送风温度,以适应工件的喷涂要求,即冬季可送热风。由于冲击风速大,噪声很大。为降低噪声对喷漆工人的危害,可增加消声风道。改

进后的大型无泵式喷漆室示意图,如图5-5-12所示。

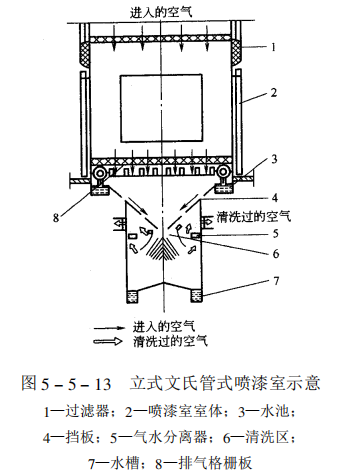

(3)文氏管式喷漆室。文氏管式喷漆室是适用大件喷涂用的室体,为密闭式的喷漆室。如图5-5- 13所示。

从图中可以看出,在排气格栅8下面,安装有喇叭形抽风罩和斜板4,这样使从喷漆室顶部送入的空气沿垂直向下方向逐渐收缩,由喇叭形抽风罩中心的间隙排出,可保持喷漆室内气流成为圆滑的层流状态,于是空气流将漆雾有效地向中央压抑而不被扩散。

当漆雾被层流状态的气流压抑到喇叭形抽风罩表面时,由于水沟3溢流,使抽风罩面上形成一-层连续的水膜。漆雾接触水膜时,就被带入水中,没有与水接触的漆雾,在排风的作用下,与水一同流向喇叭排风罩的间隙。此时,空气通过文氏管原理扩散,使水在间隙之间雾化成细滴,水滴将剩余的漆雾吸附,成为含漆雾的水滴和空气的混合体。当混合水滴群通过抽风罩下面的气水分离器中的折流板时,空气和含漆雾的水滴就分离,空气从排气管排放至室外。

随后从水槽7中,定期取出处理,即为喷漆室废水处理。

由上述可知:抽风罩中的间隙越小,雾化水的效果就越好,即文氏管式作用越显著,同时为提高净化效率,抽风机应具有足够的静压。

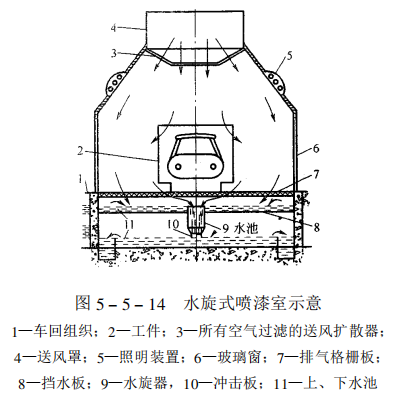

(4)水旋式喷漆室。水旋式喷漆室配置有水旋式漆雾去除装置,其主要组成为水旋器,或称旋压冲洗管。通过排气格栅下的水旋器,漆雾同空气分离,漆雾则积存于水槽中。水旋式喷漆室适用于喷漆量大、负荷率较高的连续式涂装生产线,为目前各种喷漆室中漆雾净化效率较高的一种喷漆室,一般净化效率可达92%~ 95%。

水旋式喷漆室的送风与文氏管式喷漆室相似,送风由顶部进入,经过滤、除尘、调温、调湿,均匀地送入微孔。这种喷漆室常用于装饰性要求高的喷漆,如喷涂汽车车身等。

喷漆室室内地板为排气格栅,带漆雾的空气经排气格栅排出,进入水池。水旋式喷漆室水池常由上、下两部分组成,如图5-5- 14中所示。

Among the figure, the water supply port to the top pond is not drawn in addition, that is, the top pond maintains a certain liquid level. The water with paint mist air and the upper pool can only pass through the water cyclone 9 arranged in the center. The water cyclone 9 is usually provided with 6 to 9 to reach the lower pool. When the air and water with paint mist pass through the water cyclone, the flow velocity is very high , usually about 12m/s. At this speed, the water is often broken into mist droplets, and the air and the paint mist in the air are fully mixed with the water droplets. Intense collision, in this way, the paint mist and water droplets fully react , and the paint mist will condense into paint droplets and slag. The water cyclone spray booth is a large-scale spray booth with filtration and dust removal, temperature adjustment and humidity adjustment, and is suitable for highly decorative workpieces. The internal projected area of the spray booth is designed based on the approximate air supply volume of 40000m'/h, the wind speed of the micropore air supply is maintained at 0.6m/s, the power required for air supply and exhaust is 40~50kW, and the water filtration The maximum amount of water used is approximately 130m³/h.