The anti-virus safety in painting operations mainly depends on the correct application of spray booths. When selecting or designing spray booths , it is necessary to determine the general safety technical conditions of spray booths, whether it is single-piece, small-batch production, or batch production: whether it is Whether it is independent technology or imported from abroad, it needs to meet the general safety technical conditions .

The general safety technical conditions for spray booths include the following aspects.

(1) Higher paint mist (and organic solvent) purification efficiency.

In order to achieve higher purification efficiency of paint mist (and organic solvent), the evaluation index has the following three items.

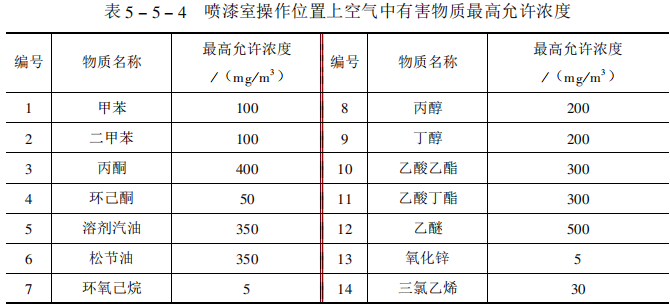

①Under the normal operating conditions of the spray booth. The concentration of harmful substances in the air at the operating position shall not exceed the regulations in Table 5-5-4.

② The interior of the spray booth is the painting area, and an exhaust system needs to be configured. For large and closed spray booths , an air supply system needs to be configured at the same time. The control wind speed adopts the regulations in Table 1 of Appendix IX.

Disturbing airflow as defined in Table 5-5-7 refers to drafts affecting the control wind speed, or the effects of operators walking back and forth. If the operator moves slowly at the operating position and closes the door during operation, the interfering air flow should be regarded as very small and negligible. For the control of large spray booths, the wind speed can be selected as 0.25~0.30m/s .

③The paint mist removal device in the spray booth should have a good paint mist purification rate (or paint mist removal rate), so that the air at the outlet conforms to CB 6514-1995 "Safety Regulations for Painting Operations-Painting Process Safety and Its Ventilation and Purification" ", which is consistent with CBZ 1-2002 "Sanitary Standards for Design of Industrial Enterprises" , that is, when the elevation of the outlet of the exhaust pipe of the spray booth is ≤20m, taking toluene or xylene as an example the maximum discharge at one time Concentration ≤ 0.3mg/m.

(2) Comply with the regulations on explosion-proof and fire-proof safety.

①The interior of the spray booth is the painting area. According to the provisions of GB 6514-1995 "Safety Regulations for Painting Operations-Painting Process Safety and Ventilation and Purification", it is a secondary operation hazard area, and it is not suitable to install electrical equipment and appliances; when it is necessary to install It should comply with the provisions of the electrical design code for secondary explosion hazardous areas.

②The space outside the open surface of the spray booth within a vertical and horizontal distance of 3m is a Class III explosion hazard place no electrical equipment and appliances, such as switch cabinets, power boxes, distribution boxes or drive boxes , should be installed in this space as much as possible. Electrical units, etc.: If it has to be installed in this space, the technical configuration should comply with the provisions of the Electrical Design Code for Class III Explosion Hazardous Locations.

③ For the exhaust fan unit and the co-exhaust fan room configured with the spray booth, explosion-proof fans should be selected in accordance with the regulations for Class III explosion hazard places.

④A closed spray booth must be provided with a pressure relief window whose area is 5%~22% (square meters) of the internal volume (cubic meters) of the spray booth.

⑤ The body of the spray booth should be made of flame retardant materials. The inner wall of the chamber is smooth and flat, which is easy to remove accumulated paint and prevent deflagration of accumulated paint.

⑥ Doors should be installed at the entrances and exits of closed spray booths, and the doors should be opened outwards. If the door is opened by electric, hydraulic or pneumatic control, it shall also have the function of manual opening.

⑦ For the paint spraying room that uses oil as the medium to absorb paint mist in the air, the volume of the oil tank and its installation should comply with the provisions of TJ 36-87 "Code for Fire Protection Design of Buildings".

(3) Noise prevention safety The noise of fans, water pumps or oil pumps, valves and air pipes supporting the spray booth must not affect the operators, and should meet the requirements of GBJ87-85 "Noise Control Specifications for Production Processes of Industrial Enterprises" Regulation. Vibration reduction, vibration isolation to reduce the noise level and reduce the impact on operators.

(4) The paint mist coagulant selected for anti-corrosion safety is as weakly alkaline as possible. When the selected paint mist coagulant has to be strongly alkaline, the inner wall of the Water Tank (pool) in the spray booth should be coated with anti-corrosion materials, such as Heavy anti-corrosion epoxy resin paint, etc.

(5) Labor operation safety.

① The exhaust fan in the spray booth should be linked with the spraying equipment, that is, when the exhaust fan fails, the spraying equipment will send a stop signal, and the spraying equipment can enter normal operation only when the exhaust fan resumes normal operation.

② Around the working position of the spray booth, the operator's head, hands, arms, legs, and feet should have sufficient room for movement, and the operator should be considered to alternately use the sitting and standing postures. Generally, the alternate use of sitting, standing, and walking should be considered. The operating posture, and the space and supports it requires.

③ It is advisable to use an effective paint mist coagulant for spraying operations to improve the purification rate of paint mist and help the wastewater treatment in the spray booth.

④ In order to carry out the spraying operation in the painting room, the minimum illuminance is 500 lux when mixed lighting is used; the minimum illuminance is 150 lux when general lighting is used.

⑤ When the spraying operation and maintenance work position in the spraying room is above 2m above the bottom surface, it must be equipped with a standing platform, a fall-proof fence and a protective plate, and it should comply with the relevant regulations on high-altitude operations:

GB 4053.1 "Fixed Steel Straight Ladder"

GB 4053.2 "Fixed Steel Inclined Ladder"

OB 4053.4 "Industrial Steel Platforms"

(6) Safety supervision.

①The spray booth shall be manufactured in accordance with the design drawings of a professional design institute with a professional design certificate for painting, or the design drawings provided by a unit approved by the competent department above the provincial level.

②The spray booth should have the technical documents of the appraisal meeting attended by the national labor safety and quality supervision and inspection agency, product nameplate, instruction manual and inspection certificate.

③Before the spray booth is delivered for use, the user unit shall conduct the completion acceptance together with the design unit (or selection unit) and the production plant. It is required to meet the design performance index, performance inspection and test data complete. Under the condition of rated production capacity, the labor, safety and sanitation requirements of the original design are met.

④ The spray booth shall carry out at least one ventilation system efficiency technical appraisal and electrical safety technical appraisal , and record the appraisal results in the file.