As an anti-corrosion primer, epoxy zinc-rich paint is generally applied to the surface of the steel plate after sandblasting or shot blasting, and on the assembly line, it is very fast (usually within 10min) when the zinc-rich primer is not completely dry It is also difficult to measure the thickness of the zinc-rich paint before it is completely dry with ordinary Thickness Gauges. Therefore, the measurement of the film thickness of the zinc-rich primer has become a difficult problem. Due to the special function of the zinc-rich primer, whether the coating is leaked or whether the film thickness reaches the standard is directly related to the anti-corrosion performance of the container in future use, especially the anti-rust diffusion performance after the coating film is damaged. This makes the measurement of zinc-rich paint film thickness and its influencing factors very concerned by various interested parties. At present, there are three commonly used methods for measuring the dry film thickness of zinc-rich paint as follows.

a. Ordinary Magnetic Film Thickness Gauge

Since the roughness of the steel plate is between 25 and 40 μm, the surface roughness of the substrate will affect the measurement of the zinc-rich paint film thickness. It is inaccurate to measure the film thickness of the zinc-rich paint on the cabinet with a calibrated magnetic Film Thickness Gauge on a smooth zero plate. The dry film thickness of the zinc-rich paint should be measured by using a zero plate with the same roughness as the substrate to calibrate the film thickness meter, or by spraying the zinc-rich paint on a smooth tinplate under the same coating conditions.

b. Destructive coating Thickness Gauge (PIG)

The destructive coating Thickness Gauge (PIG) is a monitoring instrument similar to a microscope. It consists of a cutter and an optical magnifying device. The function of the cutter is to cut the paint film strictly at a certain angle to the surface of the paint film. The optical equipment enlarges the profile and displays it on a scaled screen. This value has been converted into the actual film thickness by converting the scale on the screen. The biggest advantage of the cutter is that it can measure the film thickness of zinc-rich paint when the surface is coated with other paint films, and it can measure the film thickness of multiple coatings at the same time. The disadvantage is that it will damage the paint film.

c. Ultrasonic Thickness Gauge

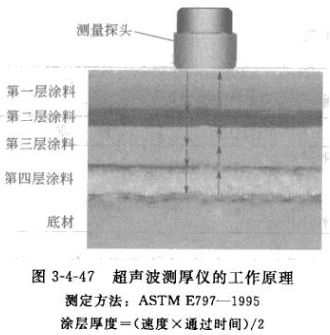

Ultrasonic Thickness Gauge is a film thickness measuring instrument that has appeared in recent years. Its principle is to use the different reflection speeds of ultrasonic waves in different media, and measure the film thickness by accurately measuring the reflection time. It can realize the inspection of the thickness of the zinc-rich paint film under other paint films without destroying the paint film, and can also measure the thickness of multi-layer paint films. Its working principle is shown in Figure 3-4-47.

Due to the characteristics of ultrasonic waves, when the content of zinc powder in zinc-rich paint is different, even if the thickness of the coating film is the same, the reflection time of ultrasonic waves in the coating film is also different (because the coating density of zinc-rich paint with different zinc powder content is There are differences), and the thickness of the coating film displayed by the instrument is also different, which requires different benchmark curves for different types of zinc-rich paint produced by various manufacturers, which increases the uncertainty of the measurement results and restricts this . widespread use of the method.