The main function of the topcoat is to shield the sun's ultraviolet rays and pollute the atmosphere from damaging the coating, resist wind, snow and rain, and have good aesthetics and decoration. The anti-corrosion topcoats with high weather resistance on the surface of steel structures are mainly acrylic polyurethane topcoats, fluorocarbon topcoats and organically modified polysiloxane coatings.

(1) Acrylic polyurethane topcoat

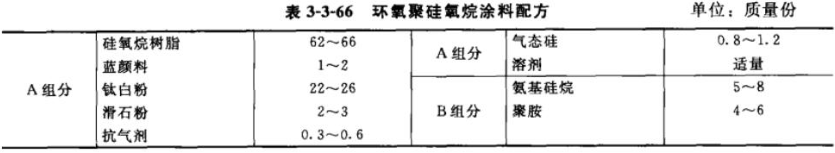

Hydroxy acrylic resin combined with aliphatic polyisocyanate prepolymer can be made into high decorative acrylic polyurethane topcoat with light color, excellent gloss and color retention, and good outdoor weather resistance. Since the acrylic polyurethane topcoat has no maximum recoating interval, some paint manufacturers directly call it a recoatable polyurethane topcoat. Acrylic polyurethane topcoat is currently the most widely used topcoat in steel structure anti-corrosion systems. Table 3-3-64 is a typical acrylic polyurethane topcoat formulation for reference.

(2) Fluorocarbon topcoat

The fluorocarbon topcoat with FEVE (polyethylene fluoride/vinyl ether) soluble fluoropolymer as the main base material can protect the underlying coating and prevent ultraviolet radiation. The high-energy C-F bond reaches 485kJ/mol, which is much stronger than the typical organic polymer C-C bond energy of 358kJ/mol. This means that a stronger activation energy is required to destroy the fluoropolymer. FEVE can be copolymerized with vinyl fluoride and vinyl ether solution to give the paint solvent solubility, transparency, gloss, hardness and flexibility. From the viewpoint of solubility in organic solvents, chlorotrifluoroethylene (CTFE) is obtained by copolymerizing vinyl fluoride. The hydroxyl functionality of the polymer can be easily prepared from hydroxyalkyl vinyl ethers, allowing it to be crosslinked with isocyanate and melamine curing agents. Table 3-3-65 is the formulation of high-gloss, matte white fluorocarbon paint and fluorocarbon varnish for reference.

(3) Polysiloxane coating

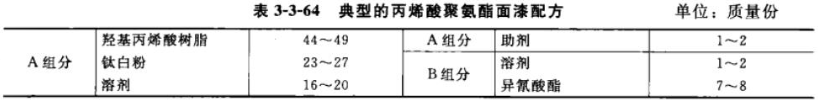

Compared with polyurethane and fluoropolymer topcoats, organically modified polysiloxane coating technology is a low-viscosity, low-VOC, isocyanate-free, high-weather resistance anti-corrosion topcoat product. The silicon-oxygen bonds in polysiloxane coatings have been oxidized making them resistant to the action of atmospheric oxygen and most oxides. The silicon-oxygen bond of polysiloxane has a bond energy as high as 445kJ/mol, which is much higher than the typical carbon-carbon bond energy of organic polymers, which is 358kJ/mol. This means that a stronger activation energy is required to break down the polysiloxane polymer. Therefore, polysiloxane topcoats are inherently resistant to atmospheric and chemical damage. The first generation of commercial polysiloxane topcoats were modified with hydrogenated epoxy resins, followed by the development of second-generation acrylic urethane and acrylic modified polysiloxane products. The low viscosity of polysiloxane resins allows epoxy and acrylic polysiloxane coatings to have high solids. The epoxy polysiloxane coating has a volume solid content of up to 90% and a VOC of 120g/L (EPA method 24). The volume solid content of the acrylic polysiloxane coating is designed to be as high as 72%, and the VOC is 240g/L. Table 3-3-66 is a typical epoxy polysiloxane coating formulation for reference.