1. Tensile testing machine

Tensile strength refers to the maximum tensile force that a paper sample per unit width can withstand before breaking . While measuring the tensile strength, the elongation of the paper can measured. At present, there are two types of testing instruments used for this indicator, horizontal and vertical, and their working principles are basically the same. The sample to be tested is fixed between the two clamps, one of which is driven by the transmission device, and the tension is transmitted to the other clamp through the sample. When the sample is broken, the pendulum device stops automatically, and the scale Indicates the tensile value.

For the tensile machine, pay attention to the following items. If you want to ensure that the tensile machine is well lubricated to avoid friction or heat; the speed- regulating friction wheel should be adjusted when the instrument is started; Clean once and fill with new butter.

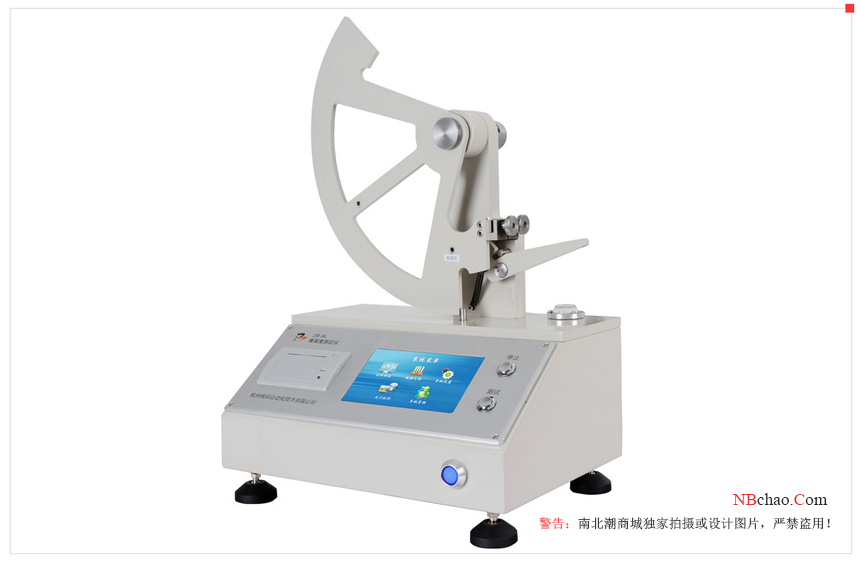

2. Tear Tester

The paper tearing degree refers to the force required to tear a certain length of paper. The measured internal tearing degree is to cut the paper with a certain length of incision , and then measure the force required to tear the paper to a certain distance from the slit. The edge tear refers to the force required to be torn apart by a force on the same plane .

The currently used tearing Tester is used to detect the internal tearing degree of paper. The instrument is designed according to the functional principle. When the centroid of the fan-shaped pendulum of the tearing Tester rises to the height to be torn, the fan-shaped pendulum is released to make the centroid position Change, change potential energy into kinetic energy and tear the paper pattern. When the instrument is verified, it is necessary to adjust the level of the instrument first to ensure that the engraved line under is flush with the left end surface of the oscillating limiter. Adjust the pointer limit: adjust the zero point to ensure that the pointer is exactly at the zero point. The sample holders need to be in the same linear position, there should be no obvious inclination or misalignment, and there should be no bending deformation of the oscillating body. The sample cutter is required to be installed firmly and keep the blade sharp. In addition, the friction of the pointer and the swing of the oscillating body must be kept at an appropriate position.

3. Burst Strength Tester

Bursting strength refers to the maximum pressure that can be withstood when pressurized at a constant speed until it breaks on a unit area of paper, expressed in hydraulic pressure or air pressure, which reflects the degree of external pressure that the paper can withstand without breaking.

It is necessary to regularly calibrate the pressure gauge of the instrument, so that the error of the pressure indication value is less than 1%, pay attention to the parallelism of the upper and lower pressure rings, and maintain the flatness of the sample pressure ring. The protruding state of the rubber membrane should correspond to the pressure indication on the pressure gauge. If the resistance of the rubber membrane is too large or cannot be restored in time, the rubber membrane should be replaced. The joints of the instrument must not have oil or air leakage, thereby ensuring the tightness of the instrument.

4. Folding Tester

Folding endurance refers to the number of times paper resists reciprocating folding until it breaks, and measures the ability of paper products to withstand folding. For paper products that need to be folded during use, folding endurance is a major indicator.

When maintaining the folding endurance Tester, pay attention to keep the moving parts well lubricated, and pay attention to verify the tension of the loading spring. At the same time, pay attention to adjust the clamping thickness of the upper and lower chucks so that the sample can be evenly clamped. After the instrument has been running for a long time, you should pay attention to check the fillet radius of the lower chuck fold, and replace it in time if there is obvious wear and tear.