The evaluation of surface roughness of steel after spray derusting can be carried out by comparison sample method, observed with naked eyes or touched by hand. This evaluation method is a qualitative and comprehensive evaluation of surface roughness.

When evaluating, first of all, according to the properties of the abrasive used in the spraying treatment, that is, the shot or the angular abrasive, select the corresponding surface roughness comparison model (“G” sample block is the surface roughness characteristic obtained by spraying the angular abrasive. The "S" sample block is a sample of the surface roughness characteristics obtained by spraying shot abrasives), and compared in turn, and a magnifying glass no greater than 7 times can be used for observation.

The international standard ISO 8503 stipulates the comparison method using the standard template for determination. Each roughness sample is a set of 2 pieces, the "S" sample after cleaning the "pill" abrasive and the "C" sample after cleaning the angular abrasive. There are 4 sets in total. The comparative sample method is a commonly used method in roughness evaluation.

my country has GB 1031-83 "Surface Roughness Parameters and Values" standard, which can measure surface roughness parameters. Generally, the average roughness value Ra, or the average roughness depth Rz, is used to measure the size of the roughness. In order to quantitatively measure the microscopic unevenness of the surface, various instruments and equipment are available on the market. Commonly used methods for measuring surface roughness are: impression method, interferometry and stylus method. Developed to the present, there are electron microscopes, optical microscopes and electronic roughness measuring instruments for quantitative determination of surface roughness. Electron microscopes, optical microscopes and other instruments are expensive, require professional training, and are not suitable for on-site use. They are rarely used in my country. The electronic roughness measuring instrument (stylus method) is mostly used in the coating process of the automatic assembly line, and there are relevant regulations in the international standard.

The principle of measuring surface roughness by stylus method is as follows:

When using the stylus method to measure the surface roughness to be tested, the stylus is directly drawn across the surface of the workpiece to be tested. Due to the unevenness of the surface to be tested, the stylus is driven in a direction perpendicular to the surface to be tested. reciprocating motion. This movement of the stylus is amplified by the electronic signal, and quantitatively displayed on the meter through the output device of the test instrument.

The instrument for measuring surface roughness by the stylus method is composed of a sensor, a driver, a zero indicator, a Recorder and a workbench. The stylus is generally made of diamond and is very hard, and the inductance sensor is the main part of the roughness measuring instrument. It should The magnitude and direction of the displacement signal of the diamond stylus can be amplified by the electronic device and divided into three paths, one path communicates with the zero meter to indicate the position of the stylus, the other path is sent to the amplifier, input to the Recorder, and the last path is distributed to the integral calculation Device, and then input to the indicator, directly read the value of the average roughness Ra.

In the past, traditional roughness measuring instruments could only measure fewer parameters, and the measurement accuracy was also low, and the reliability and error of the system were not satisfactory.

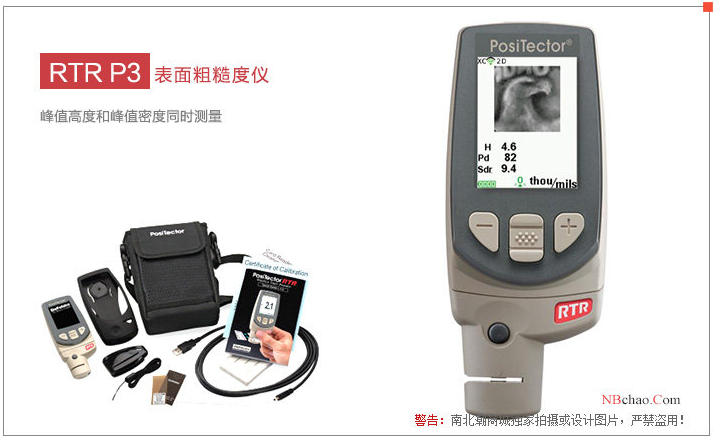

At present, the roughness measuring instrument improved by the computer system is used, and the measurement accuracy has been greatly improved and enhanced. The computer can automatically digitally filter and calculate the collected data, and change the analog signal into a digital signal, which significantly improves the reliability of the system. Moreover, the input and display can be carried out simultaneously, and the test results can be directly output on the display screen or on the printer.

At present, in actual production in our country, the surface profile (surface profile is the surface roughness) comparator and the laminated tape with spring micrometer are used to measure the value of roughness. For example, when using a laminated tape with a spring differential meter to measure the roughness value, a small piece of laminated tape should be removed first, the paper backing should be removed, and the side with latex should be placed on the clean steel surface after derusting, and then on the surface of the tape. Rub the backside vigorously with a tool until the surface of the tape turns a uniform gray. Take off the tape, measure the height of the staggered pattern on the tape paper with an elastic micrometer, and deduct the thickness of the polyester film.

There is also a digital direct-reading surface profiler, which can be placed directly on the peak of the steel surface profile, so that the probe of the probe penetrates into the valley of the anchor pattern, and measures more than 3 times until a stable value is obtained.