Determination of bursting strength

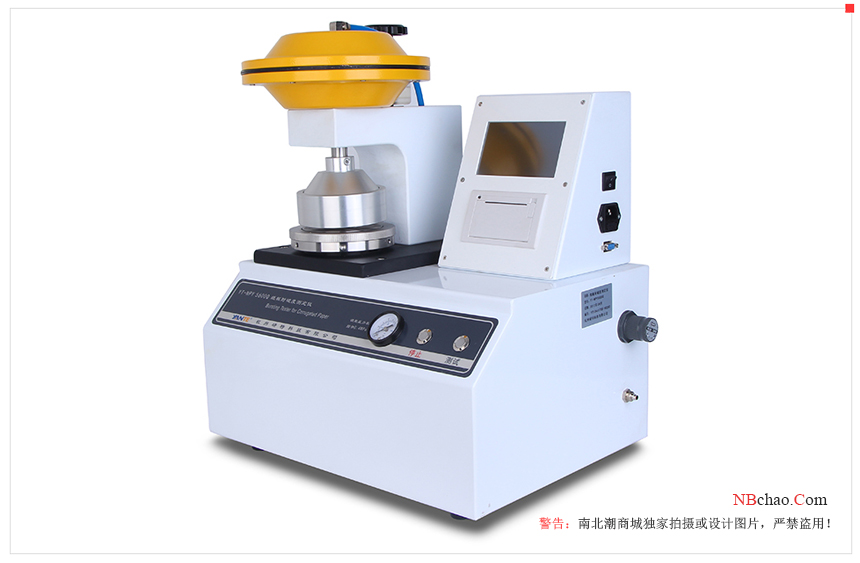

When the paper is broken, the maximum pressure per unit area can be expressed in kilogram force/square centimeter. At present, the bursting strength adopts the Mullen (Mullen) type measuring instrument, and there are two measuring methods: one is oil pressure, using glycerin as the pressure transmission medium; the other is air pressure, using compressed air as the pressure source to transmit the pressure . The rubber membrane is gradually protruded through the transmission and pressure mechanism, and the paper patterns close to the rubber membrane are broken. The maximum pressure at this time is the bursting strength of the paper.

The detection of the index of bursting strength is mainly for packaging paper, not for printing paper.

Determination of folding endurance

To measure the folding endurance of paper, a Schopper folding endurance instrument can be used. The maximum tension during folding is 1 000g, and the thickness of the paper is less than 0.25mm. The paper strip is sandwiched between two clamps with a tension of 1000g. Start the machine, fold the paper strip back and forth at 180° until the paper strip breaks, and record the number of times of movement, which is the folding endurance. Therefore, folding endurance = number of times of folding.

There is also a MIT folding Tester, which was developed by the Massachusetts Institute of Technology (MTT, Mas-sachusetts Institute of Technology), so it is named MIT, the abbreviation of this university. Its design principle is: under a certain tension, fold the paper pattern at a certain speed until the number of times it is broken.

There is a large difference in the folding endurance of paper in the longitudinal and transverse directions, and the longitudinal direction is greater than the transverse direction, but there are exceptions. Banknote paper, map paper, book cover paper, etc. in printing paper all have certain requirements for folding endurance.