(1) The emission spectrum of the light source should match the absorption characteristics and color sensitivity of the photosensitive material. The energy of light varies with wavelength and frequency. The shorter the wavelength and the higher the frequency, the greater the energy of the photon. When light is absorbed by matter in the process of radiation, since the photon has a certain energy, it will cause physical and chemical changes , and the chemical reaction caused by light energy is called photochemical reaction.

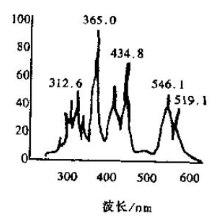

Figure 1. Spectral energy distribution of 200V, 20A carbon lamp Figure 2. Spectral energy distribution of printing plate fluorescent lamp

( 2) High luminous efficiency and high intensity. The luminous efficiency of the light source, especially the conversion rate of ultraviolet light, should be high, and the luminous intensity or brightness should be large. Under the condition that other conditions remain unchanged, the greater the power and luminous efficiency of the light source, the greater its luminous intensity or brightness, and the illuminance of the exposed surface will also increase accordingly, and the time required for the photosensitive material to obtain the same exposure will be shorter. .

Saving electric energy, shortening plate-making time, and improving production efficiency have always been the pursuit of screen printing plate-makers. Some units have been using ammonium dichromate-PVA photosensitive adhesive in the past, avoid strong use of argon lamp and general fluorescent lamp for printing, and after using diazo and acrylic photosensitive resin (photosensitive adhesive), also use fluorescent lamp for printing. As a result, 60 minutes of selenium is not good. After switching to black light, it only takes 5 minutes to complete. Therefore, the energy consumption is reduced to less than 1/10, and the plate making speed is increased by more than 10 times. Some units are exposed with carbon lamps and xenon lamps. A 3KW light source was exposed for 10 minutes, but it took 5 minutes with a 200W black light. The energy consumption ratio is 30:1. This fully demonstrates the significance of choosing a reasonable light source in saving energy and improving production efficiency.

Acryloyl photosensitive material is used as screen printing photosensitive glue, its photopolymerization is caused by the photoinitiating system, and its color sensitivity mainly depends on the sensitization-initiating system. In the case of using benzoin ethers, benzophenones, acetophenones and benzoin dimethyl ether, the color sensitivity range is between 250 ~ 390nm, and the peak is between 300 ~ 360nm, so, more It is best to use high-pressure mercury lamps, black light lamps, etc. Metal halide lamps, monochromatic fluorescent lamps, and blue lamps are all less effective. When the sensitization-initiation system composed of thioxanthone derivatives and tertiary amines is used, the color sensitivity is 250~430nm, and the peak value shifts to around 390nm, so monochromatic fluorescent lamps are satisfactory light sources, high-pressure and ultra-high pressure mercury lamps And metal halide lamps can be better matched. When coumarin ketones and amines are used as the sensitization-initiating system, the color sensitivity range can be extended to around 600nm, and the peak value is between 450 and 500nm. Therefore, various light sources are very effective, even argon laser sources, Light sources such as aviation lamps, carbon lamps, sunlight, and fluorescent lamps have all become practical. It's just that such photosensitive materials need to be operated in a dark room.

( 3) Safety and sanitation. The printing light source requires a particularly high voltage, so safety measures for electrical failures are required. In addition, the light source generates heat during use, so special attention must be paid to heat dissipation. Ultraviolet rays emitted by the light source can damage the eyes and skin, so environmental management at the operating site is very important. As we all know, the carbon lamp has a wide spectrum distribution range, and the ultraviolet light emitted by it has a strong harmful effect on the human body. This type of light source produces ozone during use, and a small amount of ozone is good for people, but a large amount will seriously damage human health.

( 4) Workability and economy. In plate-making, daily operations such as replacement of light sources and site cleaning are required, and certain skills are required, so it can be said that the use of light sources is a cumbersome task. Its operating cost is also a very important issue, so it is necessary to carry out comprehensive cost accounting on the lamp life (effective time), glare time, labor costs, and depreciation of lamps. Therefore, light sources that can start up instantly, have high resistance to switching times, have a long life, and can reach the rated brightness in a short time after starting up are generally welcomed by plate-making manufacturers.

( 5) The reproducibility of the image is good. Image reproducibility refers to whether the plate film faithfully reproduces the image on the base plate, and the reproducibility is determined by various factors such as light source, printing, and developing. The reproducibility of the image is also affected by the degree of adhesion between the master plate and the photosensitive film and the direct exposure of light.

( 6) The spectral energy is stable. The stability of the energy distribution law of the radiation spectrum of the light source is better. During the effective period of use, there should be no obvious change in the distribution of spectral energy.

( 7) The heat radiation of the light source is small. Under the premise of ensuring that the light source has sufficient luminous intensity or brightness, the heat radiation of the light source should be as small as possible. When using a high-power strong light source, it is necessary to take measures such as forced cooling (air cooling, water cooling) for the lamp tube, and other measures to control the temperature of the exposure surface of the photosensitive material below 32°C.

( 8) Uniform luminous intensity. The luminous intensity of the illuminated surface of the light source should be as uniform as possible. The design of the exposure device should ensure that the difference in illumination at each point on the exposure surface of the photosensitive material does not exceed 15%.

( 9 ) Strong adaptability to light source environment. The light source should have a strong ability to adapt to the environment, and it can work normally under various temperature, airflow, and voltage changes.

Of course, in actual production, it is unrealistic to choose a light source that can fully meet the above requirements. The purpose of proposing the above selection principles is just to hope that the plate-making operators should consider the influence of the light source on the exposure quality of the photosensitive material when choosing to use the plate-making light source, so as to be targeted.