Aluminum is a metal material widely used and developed rapidly in modern industry. The appearance of aluminum products has a silvery white luster and has a good printing effect.

There are two types of aluminum materials for packaging: aluminum alloy sheet and aluminum foil.

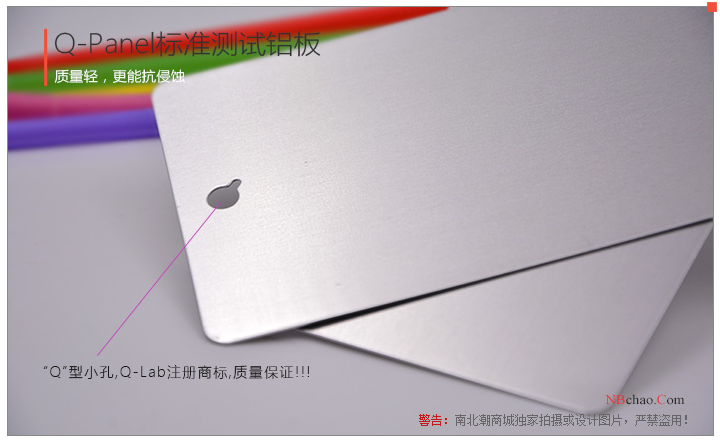

(1) Aluminum alloy sheet

Industrial pure aluminum contains more than 99.0% aluminum, and its strength is low. Adding one or several other elements such as magnesium, manganese, and copper to aluminum alloys can significantly increase its strength and hardness. Aluminum-magnesium alloys and aluminum-manganese alloys are commonly used for packaging, also known as anti-rust aluminum alloys. It is characterized by strong corrosion resistance, good polishing performance, and long-term storage can keep the appearance bright.

①Aluminum alloy sheet grades : The representation method of aluminum alloy grades in CHINA is represented by Chinese pinyin letters and sequence numbers, such as industrial pure aluminum ( L1, I2, L3, L4, I5, L6), anti-rust aluminum ( LF1, IFP2, LF3 ...), duralumin (LY1, LY2 ...). Anti-rust aluminum LF2 can be used for can making.

②Corrosion resistance : Aluminum is a chemically active element. It combines with oxygen in the air to form an aluminum oxide (AL0) film. This film can prevent aluminum from continuing to oxidize and protect the metal from corrosion. The higher the purity of aluminum, the stronger the corrosion resistance, because the presence of impurities can not only affect the bonding force between the film and the metal, but also cause other forms of corrosion, which should generally be limited to less than 0.4%. Rust-proof aluminum alloys generally have only slight surface corrosion such as pitting corrosion and spot corrosion. However, if the magnesium content in the aluminum-magnesium alloy exceeds 5%, the corrosion resistance will decrease significantly, and as the magnesium content increases, the corrosion will become more serious, which is due to the formation of aluminum-magnesium compounds.

③Paintability : Aluminum has better adhesion to paint and printing ink than tinplate, between improving paint adhesion can be solved by surface treatment before paint, including chromate treatment and sulfate Two methods are handled.

(2) aluminum foil

Aluminum box generally refers to pure aluminum with a purity of more than 99.5% rolled into a film with a thickness of less than 0.2mm, and there are also aluminum alloy boxes. Good shape stability at high-low temperatures. Aluminum foil can be printed, colored, embossed, surface coated, glued, painted, etc., or processed into composite materials with plastics and paper.