The importance of drop testing and impact testing in evaluating the fragility of packaged products cannot be overemphasized. It also stimulates shocks that packaged or palletized products may encounter during manual or mechanical handling. The ongoing impact on this product is similar to that experienced in a distribution environment or to end users.

Why is drop testing necessary?

Help with Design Verification

Evaluate designs by measuring and defining a product's impact resistance

Reproduce the rigors that may occur during distribution, installation, or use

Identify any failure modes and or quantify failure levels

Ability to evaluate packaging

Protect products by understanding the performance of the cushioning materials used.

advantage

Drop and shock testing enables you to:

Stimulate a real impact on the finished product or product.

Summarizes detailed technical information about the performance of the product under impact.

Why is drop testing required?

Drop testing is used to evaluate a product's fragility by subjecting it to sustained impacts similar to those experienced by the end user. The Drop Tester is designed by the drop test machine supplier to drop a test product with a weight of up to 1kg from heights in different directions. This process helps ensure that the tests you conduct provide reliable data to assess your product's weaknesses.

Suitability for drop testing

Drop testing is typically performed on small (<1kg) products that are either hand-held or mobile. Any device that is likely to be dropped should be drop tested during development to make sure you don't get any surprises. A typical list of products that can be inspected includes:

mobile phone, mobile phone, smartphone

tablet

two-way radio, portable radio

Handheld and Vehicle GPS Units

remote control

Transmitter and Receiver

Mobile EFTPOS device

Flash drives, hard drives and pen drives

medical equipment

Test equipment including handheld meters

tools, analytical equipment, etc.

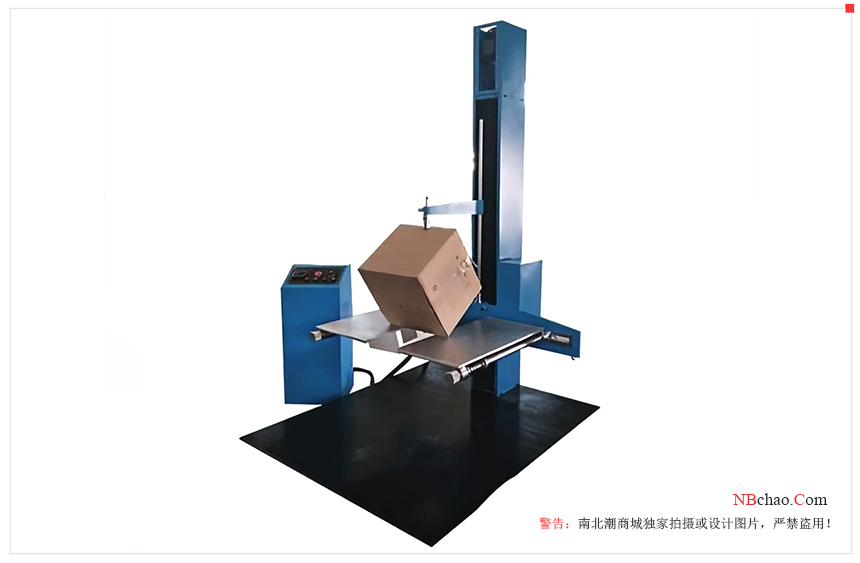

Automatic Drop Tester

The function of the Drop Tester is automatic. So, all you need to do is set up the settings according to your needs and start loading products. It is also easy to install and operate. It works without specialized training.

Automatic drop testing machines come in a variety of designs, including single, double, digital, large, and more. These are also very durable. Drop Tester suppliers in India also offer manual Drop Testers.