Resin products account for an increasing proportion of our daily lives. The color of the resin has a great influence on the color difference of resin products such as injection molding. Therefore, in the production process of resin, the color requirement of the product itself is very high. The cs-810 Spectrophotometer has been well used in the resin industry.

Unstable source of raw materials is one of the main reasons for resin color difference. The same batch of raw materials will have a certain color difference due to the difference in the mining area, resulting in the color difference of the resin product, which has a great impact on the product quality. Therefore, it is necessary to distinguish the color difference of the resin.

The customer attaches great importance to continuously improving the quality of resin products and strives for perfection. In the past, there was no fixed standard for color difference comparison in the production process, and it was all based on experienced masters. Now they are looking for a more accurate method, using transmission liquid spectrophotometry. Instrument CS-810 to improve the quality of resin products.

Transmission Liquid Spectrophotometer CS-810 is a high-performance spectrometer specially designed to measure liquid transmittance, absorbance, concentration, chromaticity and other parameters. The instrument adopts D/8 measurement structure, integrates full-band light source, single grating optical path spectroscopic system, ETC real-time calibration and other technologies, so that the resolution of the instrument can reach 0.0001, the standard deviation of transmittance is within 0.08%, and the chromaticity value: ΔE *ab 0.015. Among them, the ETC real-time calibration technology (Every Test Calibration) is that the instrument will calibrate the system hardware and software every time it is measured. This technology solves the problems of long-term measurement stability and data drift of color measuring instruments. Caipu Technology has a number of national invention patents in this technology. Eliminates the subjectivity of visual colorimetry, providing greater sensitivity and repeatability. At the same time, the instrument can be used through the connection of PC and color management software, which is convenient for enterprise quality monitoring and color data management. It can digitize the user's color management, compare color differences, generate test reports, provide a variety of color space measurement data, and customize the customer's color management work. Meet customers' high requirements for color quality.

So how to use the color spectrum transmission liquid Spectrophotometer to measure and distinguish the color difference of the resin? Here is the introduction:

Step 1: Install the instrument and software, connect the CS-810 to the computer, turn on the instrument, calibrate the instrument in black and white, and prepare the standard sample and several samples of the resin to be tested;

Step 2: Open the sample chamber, put the standard sample of resin in and start the test;

Step 3: After the standard sample is tested, take the standard sample out of the sample chamber, put the sample in, and start the test;

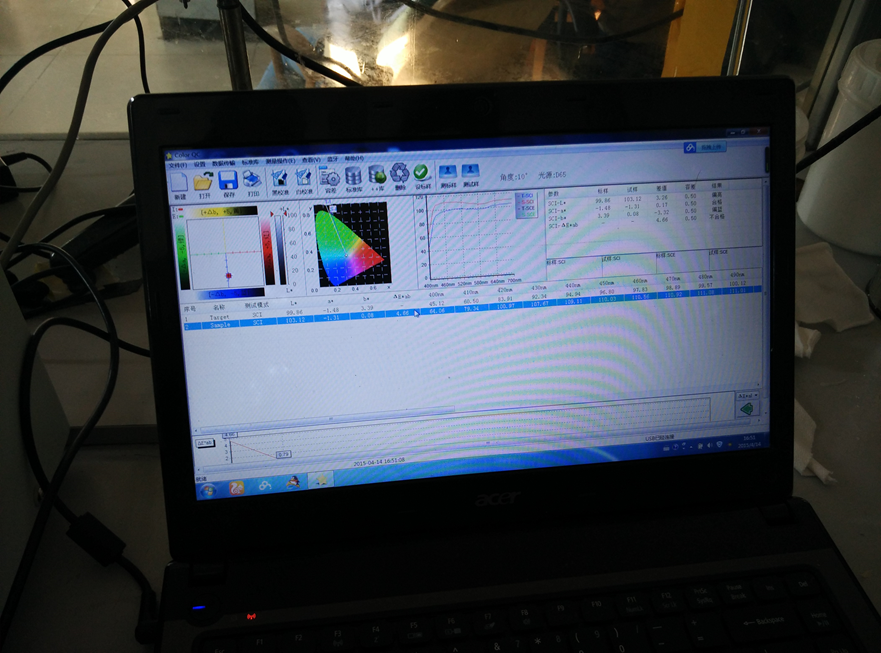

Step 4: After the test is completed, the data test data can be obtained. According to the customer's request, other resin samples can be measured and the specific and accurate data of the measurement can be obtained.

After measuring the resin standard sample and several samples, the customer is very satisfied with the test results. The direct data reflects the accuracy of the transmission liquid Spectrophotometer , which satisfies the increasing accuracy of resin color difference in the process of resin production. The requirements are conducive to the improvement of product quality, and at the same time, it is also very helpful to the improvement of the production efficiency of the enterprise, ensuring and improving the credibility of the enterprise. I believe that we can reach further cooperation and common development in the future!