Azo-condensed pigments are one of the new organic pigments, with a wide spectrum of color distribution, covering from green light yellow to blue light red, from purple to brown. Because of its good light fastness, solvent resistance and migration resistance, azo condensation pigments are widely used in plastics, coatings, printing inks and other fields. CI Pigment Red 166 is a very bright yellow light red azo condensation pigment , in the , it shows excellent bleeding resistance, migration resistance and heat resistance stability, and has 7-level light fastness performance [2,4]. Its structure does not contain banned aromatic amines, and can be prepared by low-cost and environmentally friendly processes. However, in ink coloring, CI Pigment Red 166 has poor transparency and gloss, which restricts its application in printing ink.

"Mixed crystal" technology, also known as solid solution technology, is a widely used organic pigment modification technology. Mixed crystal technology is to use two or more components with different X-ray diffraction characteristics and different branch structures to form a mixed crystal product in a specific molar or weight ratio. Mixed crystal technology not only changes the chemical structure of organic pigments, but also adjusts the particle size and distribution of pigments, and improves the coloring . The "mixed crystal" technology of organic pigments is mainly implemented . One is through the physical process of dissolution-precipitation or grinding, such as dissolving pigments in concentrated sulfuric acid at low temperature, then diluting them in water or organic solvents , and filtering out the mixed crystals. Crystal pigments , etc.; the other is formed by chemical reactions .

In recent years, many foreign companies have published patents on the application of mixed crystal technology to organic pigments, including azo pigments, heterocyclic pigments, fused ring ketone pigments and copper phthalocyanine pigments, such as naphthol-AS pigments CI Pigment Red 184 is a modified variety of CI Pigment Red 146; CI Pigment Red 210 is a modified variety of CI Pigment Red 170; using perylenetetracarboxylic anhydride (PTCA), perylenetetracarboxylic monoanhydride p- ethoxybenzamide and 3,5-Dimethylaniline, co-condensation reaction to generate a new structure of mixed crystal pigments, that is, CI Pigment Red 149, the molar number of which is 99% to 70%, and the molar number of asymmetric products can form mixed crystals in the range of 1% to 30% product .

For the mixed crystal technology of azo condensation pigments, there are still few related patents and documents at home and abroad. The mixed crystal acylation condensation technology adopted in this paper is to carry out acid chloride reaction between 1-(2,5-dichlorophenyl) azo-2-hydroxynaphthalene-3-carboxylic acid and fatty acid in a specific molar ratio with an acylating reagent. to form mixed acid chlorides, and then carry out condensation reaction to prepare modified mixed crystal pigment products. Through modification by this method , the transparency, gloss and tinting strength of CI Pigment Red 166 in offset printing ink and solvent ink application can be improved, and a high-performance organic pigment suitable for offset printing ink and solvent ink system with higher cost performance can be prepared.

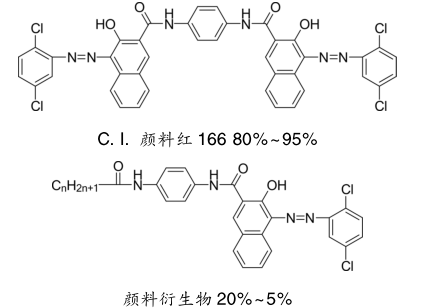

The structure and ratio of CI Pigment Red 166 mixed crystal pigment are as follows:

1 Preparation of red azo condensation pigment

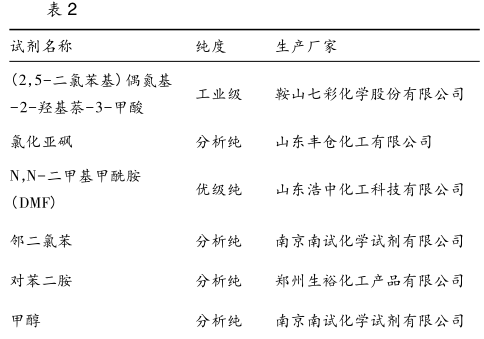

1.1 Experimental instruments and reagents

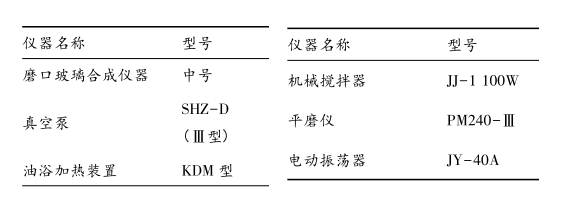

(1) The experimental equipment is shown in Table 1

1.2 Preparation process

Add a certain amount of 1-(2,5- dichlorophenyl ) azo-2-hydroxynaphthalene-3-carboxylic acid, fatty acid and ortho- dichlorobenzene . Under stirring, add a certain amount of DMF and thionyl chloride into the above system, use an Oil Bath heating device to raise the temperature to 100 °C, and react for 3 h to obtain the acid chloride. Lower the temperature to 50°C, add , raise the temperature to 150°C, and keep it warm for a period of time until the end of the amidation reaction. Inject the system into methanol prepared in advance , stir for a while, filter, and wash with methanol. 0 %。 Vacuum drying, grinding, made of highly transparent red azo condensation pigments, yield 99.0%.

2 Application Performance Evaluation

2. 1 Offset printing ink system

(1) Natural color test

Color paste preparation and determination method: at 25 °C, weigh 0.2 g sample (accurate to 0.001 g), weigh 0.5 g varnish with a sampler, and place it on the ground glass surface of a flat Grinder Mix evenly, grind 50 times each time, grind 5 times in total, and collect the slurry; pick a little slurry with a spatula and apply it on the scraper paper, scrape it off evenly with a scraper, and compare it with the reference standard under a standard light source. Compare the differences in complexion, transparency and ink color; evaluate according to the standard evaluation grades such as approximate, slight, slightly, relatively, etc.

(2) Tinting strength test

Determination method: at 25 ℃, weigh 0.05 g sample ( accurate to 0.00 1g), 1 g titanium dioxide, weigh 1 g varnish with a sampler and place it on the ground glass surface of the flat Grinder Mix evenly, grind 50 revolutions each time, grind and rotate 5 times in total, and collect the slurry; pick up a little slurry with an ink spatula and apply it on the scraper paper, scrape it off evenly with a scraper, and compare it with different titanium alloys under a standard light source. The reference standard made of white powder is compared with the shade of the complexion until it is the same as the standard, and the coloring strength of the sample is calculated according to the amount of titanium dioxide used in the standard.

2. 2 Resistance to mixed solvents

Resistance to mixed solvents is one of the important indicators of pigment application performance . Determination method: Add 7 mL of mixed solvent into a 10 mL test tube at 25 °C, weigh 0.2 g of pigment sample (accurate to 0.001 g) on fan-shaped filter paper, fold the filter paper and place it in the solvent-filled In the test tube, one-third of the filter paper was soaked with the solvent, the stopper was tightly plugged, and the test tube was placed in the test tube rack for 24 hours. After 24 hours, compare the staining level of the sample with the standard colorimetric tube to determine the mixed solvent resistance of the pigment, the worst is level 2, and the better is level 5.

2. 3 Heat resistance

Measuring method: Grind the pigment with a certain medium to form a color paste. See (GB1771-79, GB1711-89) for the formula , spray it on the tinplate, level it for 30 minutes, bake it at 100 ℃ for 1 hour, cool it to room temperature and cut it into several small pieces. Place them at 120°C, 140°C, 160°C, 180°C, and 200°C for 30 minutes, then take out and cool to room temperature for comparison with untreated standard samples.

3 Results and discussion

3.1 The effect of different mixed crystals on the performance of pigments

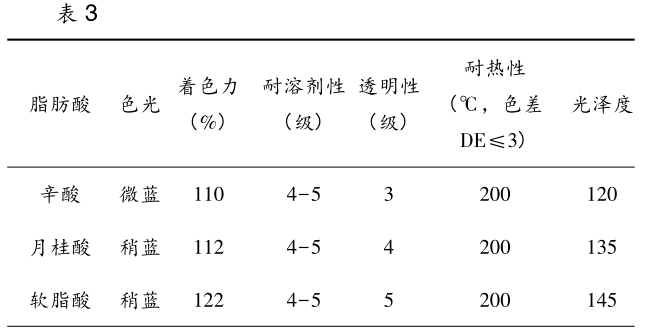

When the pigment is synthesized, straight-chain fatty acids with different numbers of carbon atoms are added to 1-(2,5-dichlorophenyl)azo-2- hydroxynaphthalene -3-carboxylic acid, and the molar ratio is 93:7; Amidation produces a pigment mixed crystal with a molar ratio of CI Pigment Red 166 and pigment derivatives of 93:7. The straight-chain fatty acids are respectively caprylic acid, lauric acid (dodecanoic acid), palmitic acid (hexadecanoic acid), and stearic acid (octadecanoic acid).

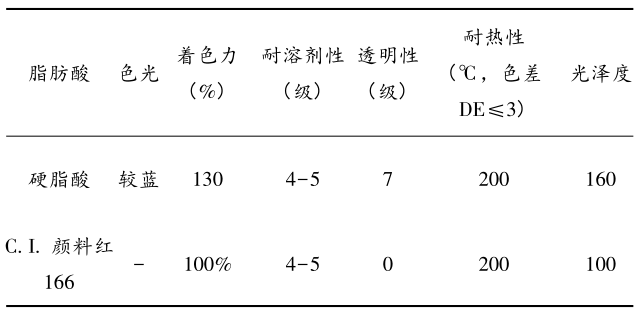

The application evaluation results of pigments prepared by different straight-chain fatty acids are shown in the table

3 (CI Pigment Red 166 as standard).

Note: Use offset printing ink to detect

It can be seen from the table that with the growth of the carbon chain of the modified fatty acid, the transparency, tinting strength and gloss of the pigment are obviously improved, the shade is bluish, and the heat resistance and solvent resistance are not deteriorated. In CI Pigment Red 166, the longer the carbon chain, the more obvious the effect of fatty acid modification