The influencing factors of film are relatively diverse, ranging from quantifiable factors such as the material itself, substrate, and proofing equipment, to small errors that are difficult to quantify such as human control and environment temperature and humidity, which are more or less critical to the precise control of the laboratory. Film has an impact. Moulding proofing is a key to laboratory testing. If it is not done well, all subject testing in the later stage is equal to zero. Therefore, how to prepare a beautiful film has become a headache for researchers, either repeatedly consuming time, or it will be used. Based on the application experience of thousands of customers, nbchao sorts out the main factors affecting film for you today, which are mainly divided into four categories:

Ⅰ. The impact of the material itself

The volatile film thickness is difficult to control

In fact, this aspect is very easy to understand. Some volatile fluids have evaporated more than half of them before you finish scraping them. How do you control the amount?

Viscosity levelling is not easy to scratch

Some samples have high viscosity and levelling is very bad. Use a wire rod to scrape the film, but it has already dried before levelling. It is strange that this situation does not scratch. In actual use, fluids with a viscosity below 1000cp use a wire rod film, and those above 1000cp can consider using a scraper type, that is, a I-type film device or a Micrometer Film Applicator.

Samples demanding of the environment

For example, glue, heating and not heating, the temperature is very different from the state, viscosity and flowability of the sample, and the preparation of such samples by hand is more cumbersome. Of course, the same is true for lithium battery film.

The impact of the material itself

From the point of view of the fineness of the material, when the sample grinding is not sufficient, the fineness of the sample itself has some particles to the particle size of 10um. At this time, you do not use a scraper or a wire rod. When the diameter of the groove is smaller than the particle size of the material itself, how can there be no scratches? Blame the film device is not good? Blame the material? Blame yourself!

Ⅱ. Influence of film substrate material

In daily applications, the substrate of film is basically Paper, film or Tinplate. But different substrate materials have very different effects on precise film control. Here are a few common situations:

Paper

We know that different paper water absorption, the absorption performance of Printing ink is not the same, the same preparation of scraping sample, coated with 20um wet film on the coated film of paper and in the ordinary printing paper, drying the thickness of dry film is certainly not the same, extreme case, you try with napkin?

film

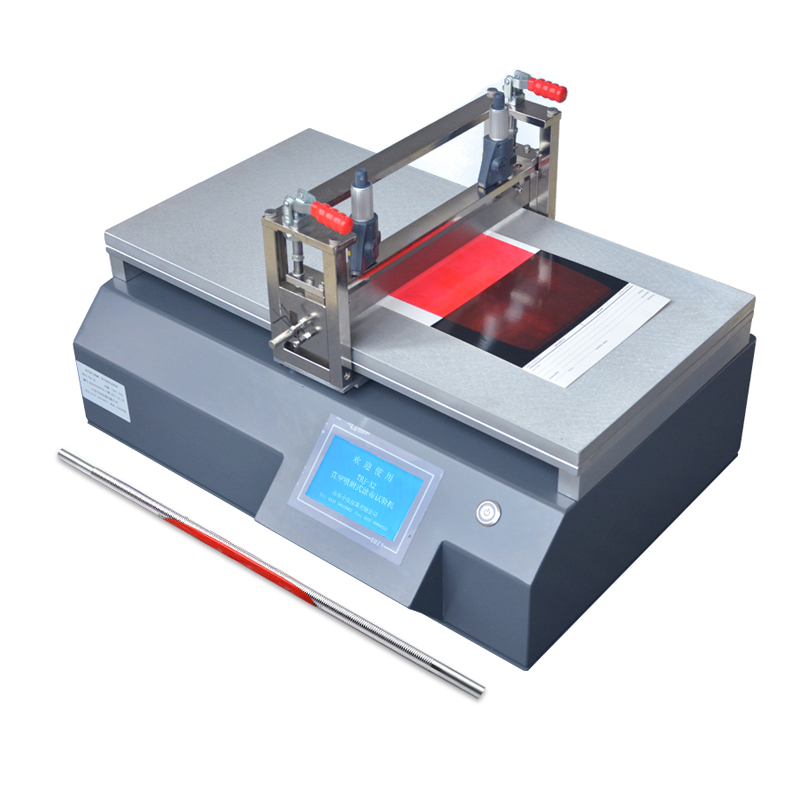

The film is mainly affected by flatness. This problem of difficulty in Moulding is commonplace among relevant researchers, and everyone knows that the most direct way to deal with it is how to flatten the film. But the reality is really difficult. There are two solutions for reference. One is to use the Drawdown Plate + bar with soft rubber pad. The film is flattened by the height difference to ensure that it fits on the soft rubber pad in good condition until it is scraped. At this time, regardless of whether the film is flat or not, the Mayer principle The wire rod can scrape the film well and ensure the film thickness is consistent; the other is to use the Automatic Film Applicator with Drawdown Vacuum Plate to adsorb the film on the film platform. In case the film is too thin and the vacuum hole is too large, a piece of paper can be attached under the film. In fact, it is the principle of Drawdown Plate. Such a film will be more beautifully painted.

Tinplate

The Mechanical Properties of Tinplate determine that it is very easy to bend and deform. The result of bending is the uneven film thickness of Moulding; this is easier to understand. One is its Roughness. If the roughness is too large, the control of the Moulding film thickness will also have a great impact. Laboratory films generally use tinned iron plates with a tin plating amount of E4, and the surface is flat and free of Miscellaneous impurities. In addition, Tinplate is affected by the size. When actually choosing a film device, you must consider its principle. The wire rod film has no requirements for the size of Tinplate, but the requirements for scraper types such as I-type Applicator and adjustable Applicator are very strict. If the choice is not good, you will not be able to scrape it out.

Ⅲ. The Impact of Proofing Appliances Accuracy

The common laboratory equipment for proofing is wire rod, Applicator, Spray Gun, Spin Coater, and the Spreader platform with wire rod and Applicator - Automatic Film Applicator. The advantages and disadvantages of different film appliances are different, and choosing the right film solution is also a major factor affecting accurate film.

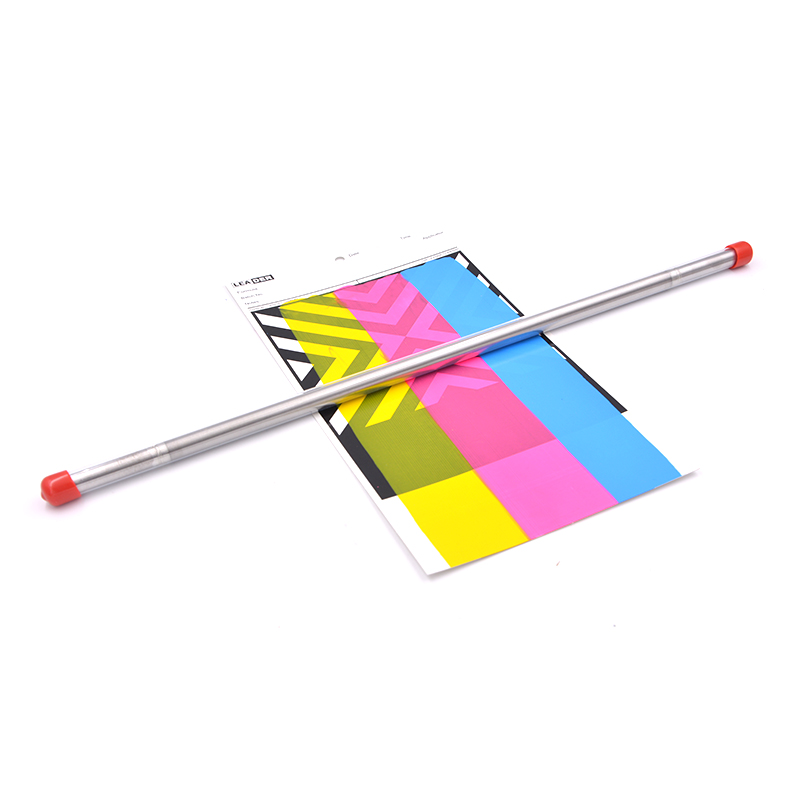

Wire rod: various film thicknesses, unlimited film environment, ultra-thin film

Due to the Mayer principle, the wire rod has the advantage that there are many options for film thickness, as small as 1.5um and as large as 200um. There are hundreds of different film thickness models. You can apply as thin as you want. The requirements for substrate size and flatness are not high, and it can also be ultra-thin film. In this regard, Miscellaneous film appliances are not comparable. The disadvantage is that cleaning is relatively troublesome. Some manufacturers advertise that extruded ones are easier to clean than wound wires. It is theoretically reasonable. In actual use, the impact of the two is not great. For specific comparison, nbchao can write another experimental draft on this issue later. Another disadvantage is that there is a limit to the viscosity. According to nbchao's experience, those within 1000CP can be used. The above must be scraper type, otherwise scratches are prone to occur. The above has already been said why it occurs.

Scraper Applicator: No scratches, easy to clean, super thick film

The disadvantage of others is the advantage of this. If you use this type of linear scraper film with high viscosity, there will be no scratch phenomenon, and it is really easy to clean. The more representative films are: I-type Applicator, Micrometer Film Applicator. The disadvantage is that the optional film thickness is not much, generally the thinnest 10um, stepped ones are: 25um, 50um, 75um, 100um, 150um, 200um, 300um, 400um, 500um, etc.

Spray-gun

This kind of large-area multi-sample Moulding efficiency is high, but the film thickness cannot be controlled. It is all based on feeling. It is unreasonable to say that it is economical. After all, it has to be matched with Air Compressor. Small film is simply not feasible.

Ⅳ. Human operation error

In addition to the influence of the above factors, the speed of the film, the process and the control of the pressure at both ends also have a great influence on the control of the film thickness, especially when the substrate is relatively soft and the pressure is too large. It is also quite common to scratch the film thickness one by one. For the material itself, the film speed with high viscosity should be slower, and vice versa, it is faster, but how fast it should be is appropriate is often based on experience. This is also the advantage of Automatic Film Applicator, which is not mentioned above.

Due to space limitations, this article will not detail how to solve the solution of accurate film Development. A good solution should be cost-effective and suitable, not cheap or expensive. In this regard, a special topic will be given later. If you need it urgently, you can click to consult the technical selection engineer of NBCHAO.

Original statement: This article is limited to NBchao. Com Mall users for reference, and forwarding is strictly prohibited!