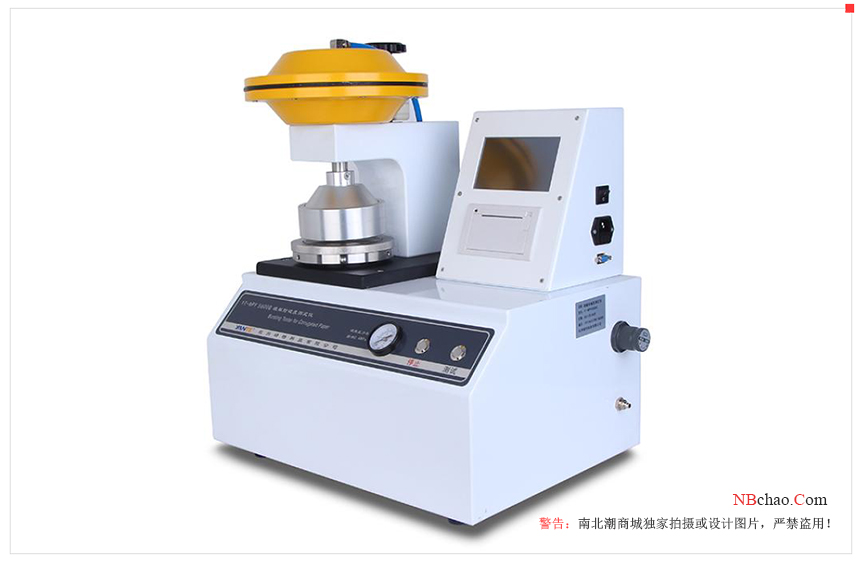

The burst Tester is a new generation of paper testing equipment. It adopts the measurement and control method with the single chip microcomputer as the core, thus realizing all digitization and microcomputerization of detection, control and data processing. All technical parameters and performance indicators are in line with the provisions and requirements of ISO "Determination of Cardboard Bursting Strength", QB/T "Paper and Cardboard Burst Strength Tester" and GB "Measuring Method of Cardboard Bursting Strength". The instrument is easy to operate, reliable in performance, and professional in technology. It is an indispensable and desirable equipment for scientific research units, paper manufacturers, packaging industries, and quality inspection departments.

Differences in Determination of Bursting Strength of Paper and Cardboard

The key to the determination of the bursting strength of paper and cardboard is the high-pressure bursting strength instrument used for cardboard and the low-pressure bursting strength instrument used for paper. The motor is different, the upper and lower pressure plates are different, the rubber membrane is different, the oil pressure rate is different, and the others are the same.

1. Usually cardboard and kraft paper (liner paper) use a high-pressure burst strength Tester with a speed of (170±15)mL/min; a low-pressure Tester for paper with a speed of 96±6mL/min.

2. The chuck size of the high pressure burst strength Tester is slightly larger than that of the low pressure Tester.

3. The test standard of bursting strength of paper: GB/T454-2002 "Determination of bursting strength of paper"; the test standard of bursting strength of cardboard: GB/T1539-1989 "Determination of bursting strength of cardboard".

After using the burst Tester

1. When the paper Burst Tester is not in use, it should be covered with a box to prevent dust from entering the testing machine and avoid being impacted;

2. Under normal use, the fixture attached to the paper Burst Tester machine needs to be wiped with a dry cloth, no need to wipe with water; if it is not used for a long time, you can wipe the surface of the fixture with a small amount of anti-rust oil;

3. The machine platform of the paper Burst Tester is generally made of aluminum or sheet metal, and generally only needs to be dust-proof;

4. Familiar with the operating procedures of the paper Burst Tester to prevent operating errors from causing damage to the testing machine;

5. Regularly calibrate the paper Burst Tester to ensure the accuracy of the instrument test results;

6. When the testing machine breaks down, do not disassemble it without authorization, but find a professional or after-sales service for maintenance, so as not to cause secondary damage to the testing machine and affect the troubleshooting and maintenance of the paper Burst Tester;

7. The working room temperature, voltage strength and power requirements of the paper Burst Tester must meet the specified requirements.