Factors affecting the homogenization effect include the product itself, homogenization pressure, wear degree of the homogenization valve, homogenization temperature, and gas content of the product. In production, we should try our best to ensure the quality of materials. However, because the high-pressure homogenizer is in a high-pressure state during operation, the parts are easily damaged, so it is necessary to check whether they are installed correctly, fastened or whether they are worn out and need to be replaced. In addition, operations under some special conditions, such as high-temperature SIP sterilization, frequent flushing and abnormal operating procedures, will affect the service life of the machine and its components. The following lists some failures of the high-pressure homogenizer, analyzes their possible causes and troubleshooting methods, so that the machine can resume normal operation.

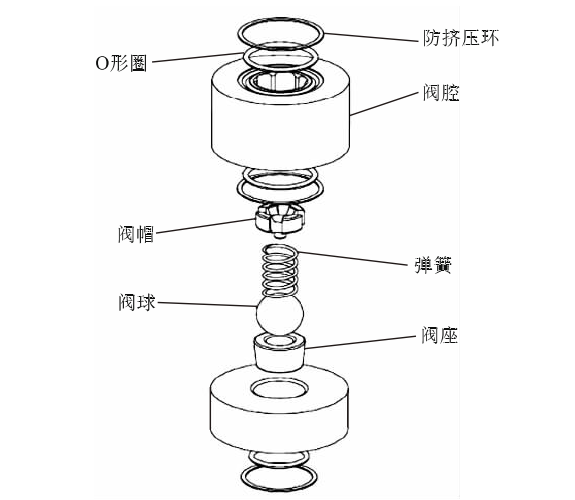

(1) The one-way valve of the inlet and outlet is leaking. The three-plunger high-pressure homogenizer contains 6 check valves, 3 of which are feed valves and 3 are discharge valves. Figure 2 is a structural diagram of the check valve of an imported high-pressure homogenizer. Leakage is usually caused by wear of O-rings and anti-extrusion rings.

(2 ) Leakage of the homogenizing valve. The internal structure of homogenizing valve is complex, including homogenizing head, homogenizing ring, homogenizing ring cavity, homogenizing seat, O-ring, guide sleeve, etc. In view of phenomena such as homogenizing valve leakage, insufficient homogenizing total pressure, failure to reach homogenizing pressure, and homogenizing valve noise, in addition to checking the O- ring, it may be caused by damage to the homogenizing head and homogenizing seat.

(3) The material flow rate slows down. Check whether the belt of the main motor is slipping, whether the speed of the main motor is reduced, whether there is leakage of the plunger seal, or air is mixed in the material, and the valve spring is broken, which will cause the material flow rate to slow down or even not flow.

(4) The main motor is overloaded. Check for excessive homogeneous pressure, worn or damaged power transmission end, excessive belt tension, or main motor failure.

In short, the frequency of failure of the high-pressure homogenizer is inseparable from whether the daily maintenance is in place and whether the operation is standardized. Therefore, in addition to the routine inspection of the high-pressure homogenizer, the gaskets, plunger seals, transfer valves, valve seats and springs, homogenizing valves, etc. should be replaced frequently according to the different materials to be processed, and the gear lubrication of the machine should be replaced regularly. Lubricating oil, water, oil and gas filters, plungers, etc.