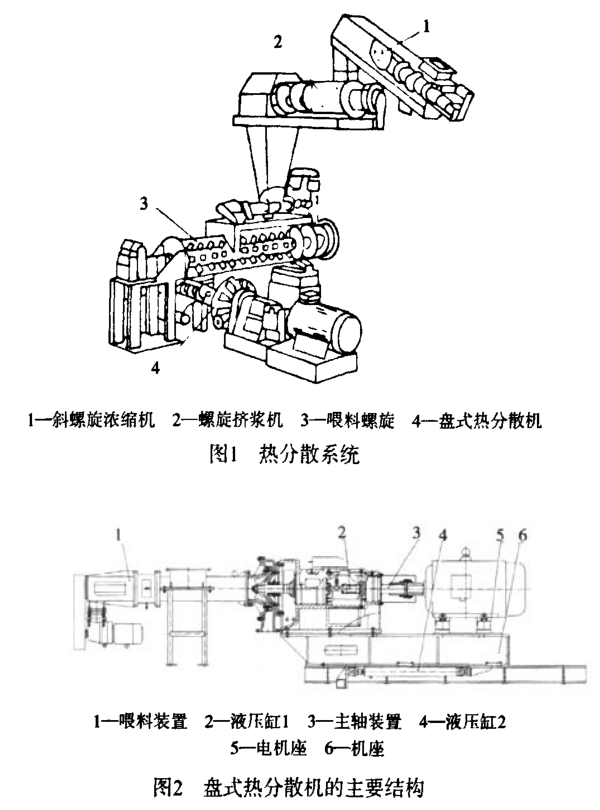

The disc heat disperser is the core equipment in the whole heat dispersing system. It is mainly composed of feeding device, refining chamber, turntable blade, transmission device, gap hydraulic adjustment mechanism and lubrication system. Its structure is shown in Figure 2.

After being heated by the thermal dispersion system shown in Figure 2, the slurry with a concentration of 25%~30% enters the disc heat disperser through the slurry inlet, and passes between the two discs sequentially under the action of centrifugal force. The gap between the dispersing teeth is 0.3~0.5 mm, and the minimum can reach 0.15 mm. Under the strong action of the dispersing teeth and the interaction between the slurry, the slurry is subjected to uniform mechanical and physical effects. Under the condition of preheating temperature, the fine sticky matter, ink, wax and other substances remaining in the slurry that cannot be removed in the screening, purification, flotation and other processes, but visible to the naked eye, are softened, and then rely on the friction between fibers, The mechanical action between the fibers and the dispersing teeth makes them thinner and disperses the invisible dust spots into the slurry.