The application of films in all walks of life is very common, such as PET film, BOPP film, PE film, PVC film, etc. In order to ensure better product quality, it is often necessary to perform performance testing on the film, so it is necessary to perform different tests on the film. coating. For example, apply stickers on the tape film, etc.

For the experimental coating, whether using a wire rod or a scraper, it needs to be carried out on a flat substrate. If the substrate is uneven, it is impossible to scrape a uniform coating, which will affect the coating effect. The film itself is very soft, easy to wrinkle and deform, and it is difficult to maintain a flat state. It is even more troublesome if it is used as a substrate. It is more laborious to manually coat the film on the film substrate. It is not even feasible to use various methods to fix and keep the substrate flat.

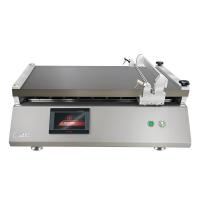

In response to this situation, various film coating machine manufacturers have developed vacuum adsorption film coating machines to solve the flatness problem of the film substrate in a targeted manner, and maintain the flatness of the substrate through vacuum adsorption. The following is the effect of the flatness of the coating film with and without vacuum adsorption by the technical engineers of the North and South Tide in the thin film experiment.

Even with gravity clamps, especially for relatively thin films, no matter how smooth they are, they will eventually wrinkle automatically.

The vacuum adsorption effect is obvious, and the film can be fixed by vacuum adsorption once it is placed on the coating table.

Through the above two videos, do you know which coating equipment to choose for coating on the film?