It is very common to prepare thin film samples for topcoat on iron plates, which can be scraped manually or automatically. Since manual coating will be affected by the factors of artificial force uniformity and coating speed stability, in the case of relatively high film precision requirements, the use of automatic coating machines can reduce the existence of manual coating through constant force and constant speed. influence factors.

This article is an experimental case of laboratory automatic coating machine used to prepare topcoat on iron plate. During the experimental operation, some small details of operation errors were shared with the users of the coating equipment to improve the efficiency of the coating and ensure a better coating effect.

First, let's take a look at how the automatic small coating machine operates. This demonstration equipment is a vacuum adsorption scraper wire rod integrated film coating machine. Since the substrate is an iron plate, there is no need to activate the vacuum adsorption function.

First, install the wire rod into the card slot of the coating machine correctly, and fix the wire rod well. Lower the pressure rod on the upper end of the Film Applicator.

Second, turn on the equipment and set the speed and coating distance. According to the speed of general manual scraping, first set the speed and the distance of scraping (coating film length). The coating speed set in this experiment is 120mm/s, and the coating distance is 250mm.

Third, evenly squeeze the coating film sample to the front end of the wire rod.

Finally, click the "Start" button in the coater display to start coating.

Check out the full operation video of the first coating experiment below.

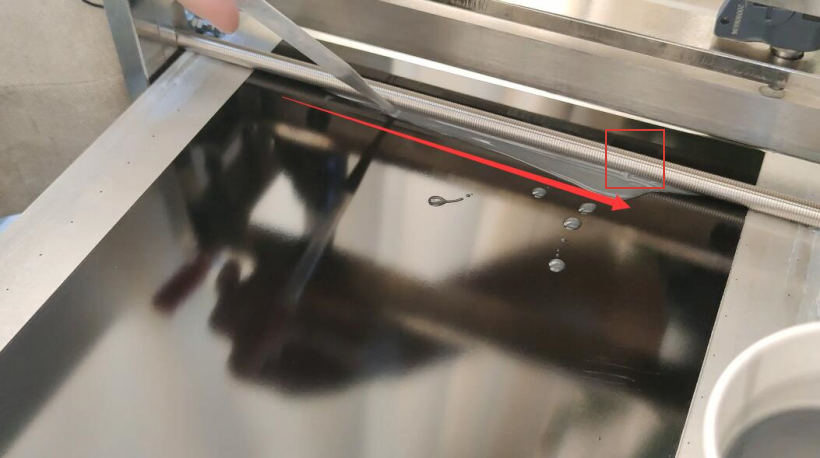

Although the overall effect of the scraped film looks good. However, in this experiment, careful or professional personnel can see that there are two small operational detail problems, so there are small local detail problems in the final coating film.

The picture above captures the picture during the operation process, which reflects two problems: first, look at the red arrow, the amount of sample extruded on the substrate is not uniform. So there is one side where no film is scraped off before the scraping ends. Second, looking at the box, a small bubble appears. In the process of placing the sample, the air bubbles that appear must be removed, otherwise it will affect the effect of the scraped film, such as a certain point of depression.

Let's look at the second correct experimental operation.

In this experiment, the imported high-precision coating rod was used for the wire rod. In addition, the pressure and speed of the automatic film coating machine were kept constant, and the above two details did not exist. A relatively uniform film was scraped and coated. This is also the advantage of the automatic film coating machine in improving the coating effect under constant pressure and constant force.