DeFelsko's PosiTector UTG ultrasonic Thickness Gauge is a non-destructive testing instrument that can test the thickness of materials. This article mainly introduces how it non-destructively measures the thickness of truck fuel tank shells and cylinder heads.

background

Tank trucks transporting hazardous materials or waste are subject to routine inspections as required by the Pipeline and Hazardous Materials Safety Administration. This inspection is carried out by qualified inspectors to ensure the safe operation and maintenance of cargo tanks, including those used to transport dangerous goods, by identifying any signs of wear, failure or corrosion.

Department of Transportation (DOT) specifications outline six tests that need to be performed on a regular basis:

1. Visual inspection

2. Internal visual inspection

3. Lining inspection

4. Leak test

5. Pressure test

6 thickness test

If a cargo tank fails any of the above tests or inspections, it will need to be repaired and re-inspected before being returned to service.

This article discusses the requirements for thickness testing and our measurement solutions.

Thickness check

Unlined tanks transporting corrosive materials require thickness testing every two years if the tank has not been used in hazmat service for one year or more, or when there are visible signs of damage.

Additionally, a high pressure leak Detector such as PosiTest HHD will need to be used. Any degraded or defective areas of the liner will need to be removed and the cargo tank walls below inspected. If corrosion is present, this area will need to be thickness tested.

Thickness testing needs to cover at least the following areas of the cargo tank wall:

• The area of the tank shell and tank, and the shell and head area around the piping where the cargo is retained

• Areas of high shell stress, such as the center of the tank bottom

• Area around openings

• Area around the weld

• Area around shell reinforcement

• Area around attachment attachments

• Coupler (attachment) area near fifth wheel

• Areas near suspension system attachments and connecting structures

• Known thin areas in the tank shell and nominal level line

• Connection structure for connecting multiple carbon steel cargo tanks to self-supporting cargo tank motor vehicles

This inspection requires the use of a wall Thickness Gauge in accordance with the manufacturer's instructions. Thickness gauges used for testing need to be able to accurately measure steel, steel alloy, and aluminum wall thickness to within ±0.002 inches (±0.06 mm).

DeFelsko measurement method

The DeFelsko PosiTector UTG Ultrasonic Thickness Gauge exceeds equipment requirements for measuring steel, steel alloy and aluminum cargo tank wall thickness. They are designed for simple operation and can be used without formal training.

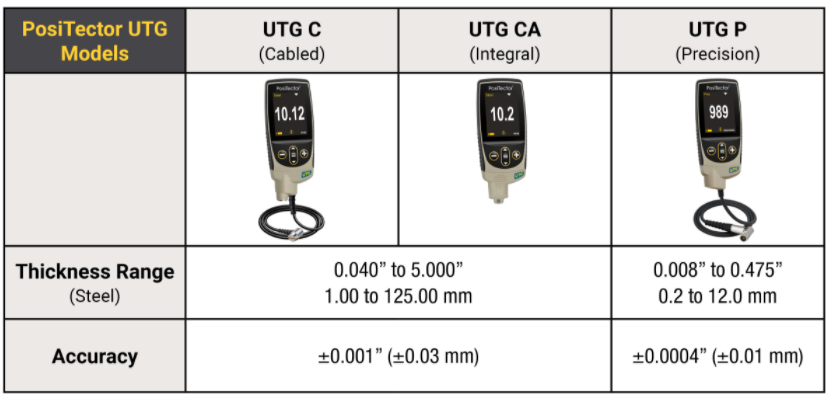

The PosiTector UTG C is available in two configurations, a corded probe (PosiTector UTG C) and an all-in-one probe for one-handed operation (PosiTector UTG CA). An exact model (PosiTector UTG P) can be used to measure tank wall thickness up to 0.040 in. (1 mm).

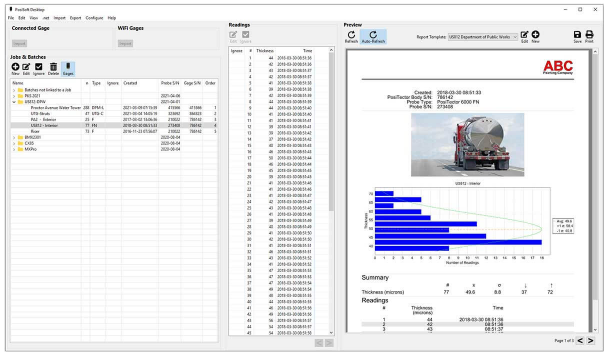

Generating professional hold inspection reports from PosiTector UTG is quick and easy. Simply connect the meter to your computer using the provided USB cable. View reports directly from PosiTector using a standard web browser, or download measurements to the powerful PosiSoft desktop software. Easily add images, annotations, and other relevant inspection information to reports. See the PosiSoft Solutions page for more information.

in conclusion

The importance of truck tank inspections in accordance with U.S. Department of Transportation specification 49 CFR to ensure the safety of operators and the public when transporting dangerous goods cannot be overemphasized. Wear and corrosion can exist anywhere on a storage tank and its components, so regular inspections by qualified inspectors are required to identify and repair these potential hazards. The PosiTector UTG is an excellent choice for measuring the thickness of truck tank shells, cylinder heads and upper coupling assemblies.