Has your experimental coating ever turned over? Although the experimental small coating machine is relatively simple to operate, it is also an automatic coating film, but if you don’t pay attention to the details, it is easy to roll over. Generally, an automatic film coating machine is selected for coating, and the requirements for the uniformity and precision of the coating film are often relatively high. Despite the veteran technology experienced in many battles, the phenomenon that the coating film will be abolished due to a little carelessness during the experiment.

Today, in order to pay attention to some details during the use of the experimental coater, we have sorted out seven operational errors and possible consequences:

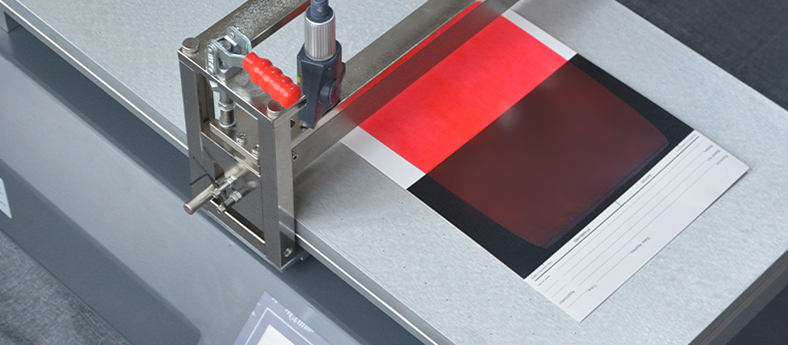

1. The wire Bar Coater is rolling during scraping

This is a relatively awkward situation. Whether the wire Bar Coater is manually scraped or automatically coated, it must be kept fixed and vertically scraped off, and it cannot be scraped off by rolling. If the wire rod is rolling during the scraping process, it means that the wire rod is not fixed tightly, and the normal small coater can fix the wire rod tightly, so that the coating film can be kept more even and uniform. Of course, with long-term use, the compression valve may also become loose, which requires maintenance.

2. The scraper presses the substrate first and then adjusts the film thickness

There are wire rod type and scraper type for small coating machines. The wire rod type is relatively simple. You only need to put the wire rod into the wire rod groove and put down the pressure rod. But the scraper is different. The scraper needs to put down the pressure rod first, and then adjust the scraper micrometer to make the scraper press the substrate, and then reversely adjust the thickness of the scraper and the substrate to control the thickness of the coating film.

Therefore, if the scraper is directly adjusted without pressing the substrate first, the thickness of the coating film will definitely be too large.

3. There are bubbles in the sample before scraping

We all know that if a viscous product has air bubbles, potholes may appear after drying. Similarly, in the experimental coating film, it is necessary to ensure that the sample squeezed on the substrate does not have air bubbles before scraping the film, otherwise there will be pits, which will affect the overall uniformity of the coating film.

If the sample extruded on the substrate has air bubbles, the air bubbles on the sample can be sucked out with a small pipette.

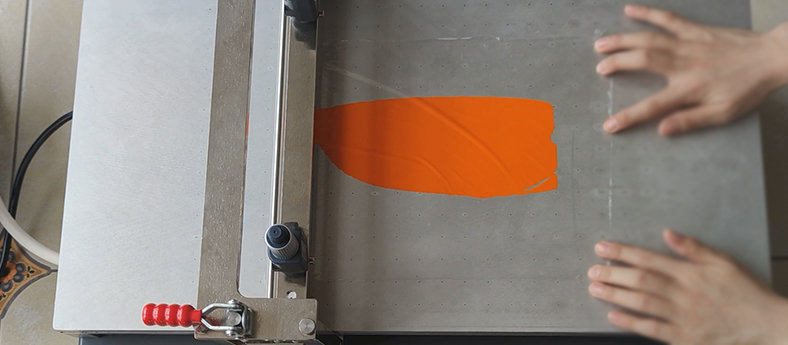

4. Speed control is too fast or too slow

Although the general sample coating speed is about 100mm/s, the coating speed to be controlled is different for different samples. For example, if the viscosity is relatively high, the speed should be slower, otherwise it is easy to scratch. The viscosity is relatively small, and the speed can be slightly faster to avoid drying too fast. In addition, for volatile samples, the speed of coating film should be faster than the speed of volatilization. Therefore, it is also necessary to try and set the appropriate speed in the adjustment of the speed.

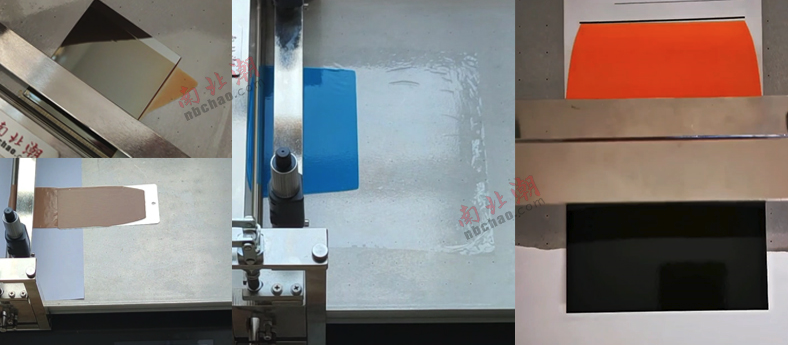

5. Vacuum adsorption is not smooth

When users use the vacuum adsorption coating machine for the first time, many of them will have a doubt, why the film is still uneven after the vacuum adsorption function is turned on. If this is the case, check whether all the vacuum holes are blocked. To make the vacuum adsorption function work normally, all holes must be blocked to avoid air leakage.

6. There are vacuum holes in the film scraped on the film substrate

For very thin film substrates, the vacuum adsorption function should be used, but there is an embarrassing phenomenon. After the scraping and drying, there are neat rows of vacuum holes on the film. This situation is mainly due to the fact that the vacuum substrate is too thin and is sucked down by the vacuum holes, resulting in holes in the coating film.

In general, there are two solutions: 1) Put a thin layer of paper on the substrate to reduce excessive adsorption; 2) Immediately turn off the vacuum adsorption function after scraping, and use the leveling property of the sample to automatically flow Flatten the entire film to alleviate visible hole spots after drying.

7. With the same stick, the hand-scraped film is thinner than the coating machine.

When this happens, it's basically a matter of stress. If the film produced by the wire Bar Coater is thicker than the manual one, it means that the load force of the pressure rod of the coater is not enough, and the pressure applied on the wire bar is smaller than that of manual scraping. At this time, it should be considered Change the load weight of the applicator. In addition, if the wet film thickness of scraping coating is less than 1.5 μm, a wire Bar Coater with a large force can also be used for scraping with a 1.5 μm wire bar.