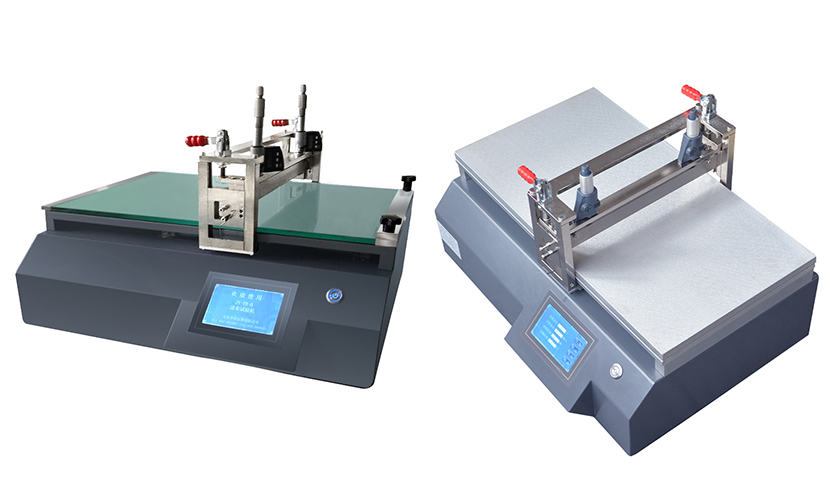

The bottom plate of the film coating machine is made of glass or aluminum alloy. If it is an ordinary film coating machine, most of it is made of glass, but if the heating function is added, the aluminum plate is often used instead. Why use aluminum panels instead of glass panels? Mainly because the thermal conductivity of aluminum plate is better than that of glass .

For the coating of rubber and lithium batteries, there are often special requirements for the ambient temperature of the coating film. It needs to be scraped normally at a certain temperature. Therefore, the generally selected film coating machine must add a heating function. Heated coating machines generally use bottom plate heating, which is transferred from the inside to the platform of the coating machine, and then the heat is transferred to the sample through the platform. The platform of the film coating machine is an intermediary of heat transfer, and the thermal conductivity of the platform material is very critical.

Although glass is generally used as the substrate for manual film coating, glass is also used as a coating platform for ordinary film coating machines, but the thermal conductivity of glass is far inferior to that of metal materials. In order to ensure better heat transfer, it is necessary to platform the film coating machine Material reselection.

So many metals, why is it aluminum alloy? If it is said that metal conducts heat quickly, it is definitely not aluminum. Silver is suitable for heat conduction, and then copper, gold, and aluminum in order. The choice of material cannot be completely based on the fast and slow thermal conductivity, but also consider the cost and safety issues. The cost of silver, copper, and gold is much higher than that of aluminum, and if the heat conduction is too fast, it may also cause accidental damage during the experiment. Therefore, from the comparison of several metals, aluminum has high cost performance and moderate thermal conductivity can better ensure the safety of operators.

Therefore, the heating coating machine generally chooses the aluminum plate as the coating platform. The heating temperature is generally within 200°C, and the heating temperature should not be set too high. If the temperature is too high, it may cause deformation of the aluminum plate. Therefore, the heating temperature supported by the general laboratory coating machine does not exceed 200°C, and the higher point does not exceed 250°C.