Many functional films, optical films, etc. are obtained by coating film modification on PET film. This article takes electronic film as an example, which requires ultra-thin coating on PET film. Electronic films are often used on mobile phones, tablet computers, displays and other components, and are coated with functional material layers on one or both sides of PET films. The thickness of the coating film is generally within 6 μm.

There are two common experimental manual coating tools, one is a wire Bar Coater, and the other is a scraper preparer. For the coating on PET film, wire bar is generally used, and wire Bar Coater can carry out ultra-thin coating, and the coating film accuracy is higher than that of scraper preparation.

In addition, due to the difference in workmanship, the coating accuracy of imported wire rod coaters and domestic coating wire rods are different. According to the experimental research of the North and South Tide, for films below 40 μm, imported high-precision coating rods are generally selected, and the accuracy can reach 0.1 μm, especially for films less than 6 μm. Domestic wire rods currently do not have thinner rods. American RDS and Japanese OSP have corresponding ultra-thin rods, RDS2# can coat 4.6μm, and OSP wire rods have rods as thin as 1.5μm.

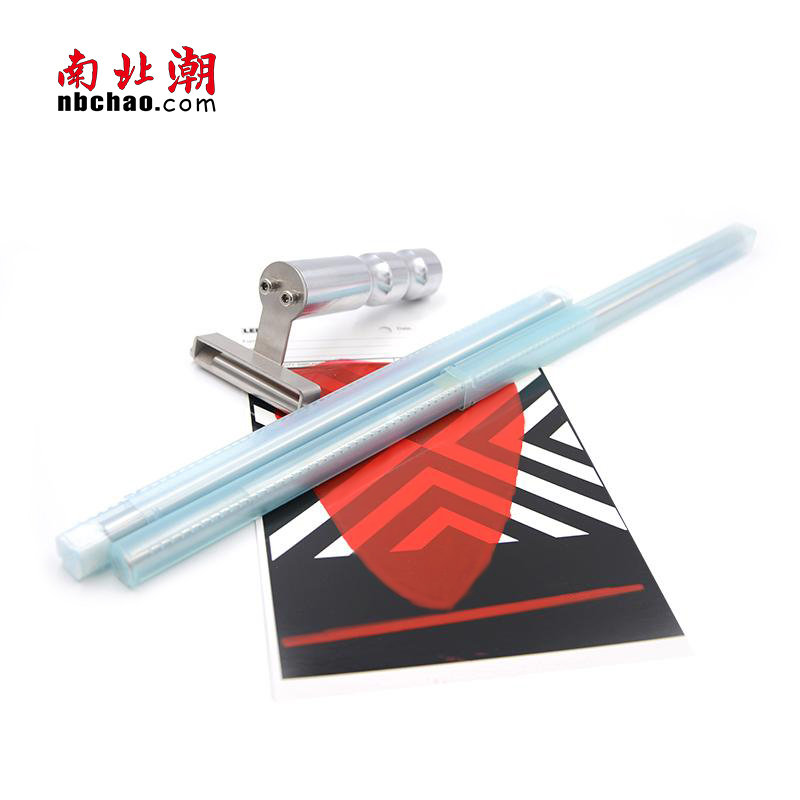

The following is the detailed appearance of American RDS and Japanese OSP wire Bar Coater.