(1) Bendtsen Roughness Meter

①Structure and working principle The Bendtsen roughness Tester used in the rapid determination method of Bendtsen instrument is a Bendtsen roughness Tester, as shown in Figure 2-9. It consists of an air supply system, a pressure regulator and a measuring system, etc. Roughness, porosity of the paper, and compressibility and elasticity. The testing principle of the Bendtsen roughness Tester is the air leakage method, that is, a weak airflow with constant pressure passes between the contact surface between the metal ring and the sample, and the air leakage is used to measure the surface roughness of the paper and cardboard. More air indicates a rougher paper or board surface. The air permeability is measured by the amount of gas passing through a certain sample area per unit time.

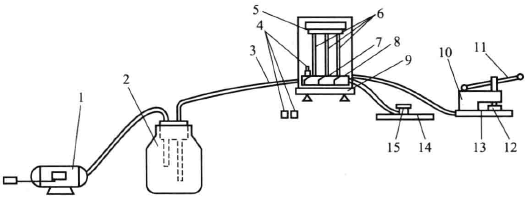

Figure 2-9 Bendtsen roughness meter

1-compressor; 2-buffer bottle; 3-trachea; 4-pressure limiting valve; 5-rack; 6-rotameter; 7, 8-control valve; 9-base; Handle; 12- air permeability probe; 13- air permeability base; 14- glass plate; 15- roughness probe

②Main technical parameters

a. Test pressure: 1kgf/cm2 or 5kgf/cm2.

b. Rotameter flow range: 15~50mL/min, 50~500mL/min, 100~1000mL/min.

c. Intake pressure: 75mmH2O (1mmHO=9.80665Pa), 150mmHzO, 225mmH2O.

③Calibration procedure, connect the capillary calibrator to the joint for measuring roughness, and then place the capillary calibrator vertically on the polished glass plate, at this time the flowmeter reading should be "0".

(2) Test method

Test according to the national standard GB 2679.4 "Measurement of roughness of paper and cardboard (Bunsen-style roughness meter rapid test method)". The specific test steps include the following points.

①Sample collection and processing. Sampling according to GB 450, cut 100mm×100mm samples along the transverse direction of the paper web, 10 pieces on the front side and 10 pieces on the back side. The sample should be flat and free from wrinkles. According to the requirements of GB 10739, carry out temperature and humidity pretreatment on the samples.

②After checking the airtightness of the instrument, place the sample on the glass plate with the measuring surface of the sample facing up.

③Start the instrument, put the pressure regulating weight of 150mmHzO on the fixed column, and turn it to move the ventilation valve, so that the air passes through the flowmeter. Place the measuring head on the sample, and read the value indicated by the float on the flowmeter after 5s, which is the roughness of the sample. The indicated value of the float should be within the range of 10% to 90% of the scale value of the flowmeter during the measurement.

④According to the above method, test each sample, and each sample can only be tested once (front or back). After the test, first remove the pressure regulating weight, and then stop the instrument.

The test results are expressed as the arithmetic mean of the positive and negative test results, and the maximum value, minimum value, and the difference between the front and reverse roughness are stated in the test report. The smaller the average value, the higher the smoothness of the sample,

(3) Factors affecting Bendtsen smoothness

① Whether the flow meter and pressure regulating weight of the instrument are adjusted vertically.

② When there is air leakage between the pressure regulator and the flowmeter, the reading is low; when there is air leakage between the flowmeter and the measuring head, the reading is high.

③Whether the measuring head is damaged or rusted.