The whiteness of paper and cardboard refers to the reflectance of the surface of white or close to white paper or cardboard to blue light, expressed as a percentage relative to the reflectance of the surface of the magnesium oxide standard plate irradiated by blue light. The ability of this kind of paper or cardboard to reflect after being exposed to light is also the brightness of the paper or cardboard, so it is also expressed by brightness.

(1) Structure and working principle

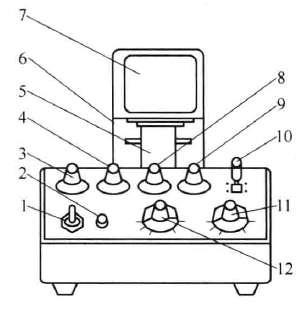

Figure 2-14 shows the structure of the ZBD Whiteness Meter, which is used together with the AC15/4 DC radiation galvanometer indicating the zero position to measure the flatness of paper, cardboard, cloth, powder, chemical fiber, paint, detergent, etc. The whiteness of products, ceramics, enamel, flour, starch and other items and the fluorescent whiteness displayed by fluorescent whitening agents in materials.

Figure 2-14 ZBD Whiteness Meter structure

1-switch; 2-indicator; 3-sensitivity knob; 4-zero adjustment knob; 5-tray; 6-sample; 7-measurement head; 8-coarse adjustment knob; 9-fine adjustment knob; 10-selection switch; 11, 12-Reading Knob

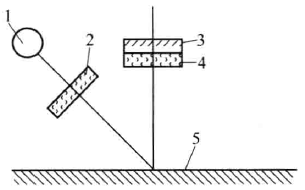

Figure 2-15 Working principle of ZBD Whiteness Meter

1-light source; 2,4-filter; 3-photocell; 5-sample

The working principle of the ZBD Whiteness Meter is shown in Figure 2-15. A tungsten lamp is used as the light source. The light beam is projected on the sample at 45°, and the photocell is used to receive the luminous flux diffusely reflected by the sample in the normal direction. The whiter the sample, the greater the luminous flux received by the photocell, and the greater the output photocurrent. The whiteness of the sample satisfies a linear relationship with the photocurrent output by the photocell. There is a filter between the main light source and the sample, which absorbs visible light with a wavelength above 500nm and a part of blue light, and has high transparency to ultraviolet light with a wavelength of 360-400nm, while the transparency of the second filter eliminates The reflected ultraviolet light is allowed to allow the blue light with a wavelength of about 440nm excited by the ultraviolet light to enter the photocell.

(2) Main technical parameters

① Measuring range: 0°~110°.

② Measuring hole diameter: 32mm.

③Effective wavelength: 445nm.

④Spectral characteristics: 45°/o°.

⑤Stability: 0.5°.

⑥Reading accuracy: 0.2°.

(3) Calibration procedure

①Turn the selector switch to the upper part, turn the knob counterclockwise, and adjust the galvanometer to zero position with the zero adjustment knob.

②Put the standard whiteness board on the sample tray, adjust the reading knob to the whiteness value marked on the whiteness board, turn the selector switch to the lower part, adjust the coarse adjustment knob and fine adjustment knob, so that the light point of the galvanometer indicates the zero position After that, turn the selector switch to the upper position.

③Remove the whiteness board, replace it with a black tube, turn the reading knob to "0", turn the selection switch to the lower part, and gently adjust the zero adjustment knob to make the light point indicate the zero position, then turn the selection switch Pull to the top.

④After repeating ② and ③, adjust the instrument with a standard whiteness board.

(4) Test method

Test according to the national standard GB 1542 "Measurement of Whiteness of Paper and Cardboard (Blue Light Method)".

① Calibration of the working standard whiteness board The working standard whiteness board is mainly used to calibrate the instrument, and its calibration is carried out with a completely reflective diffuser with a reflectivity of 100%. On the premise of confirming that the parameters of the instrument meet the standard requirements, adjust the zero point of the instrument with a black tube, calibrate the instrument with a reference complete reflection diffuser, and use the working standard plate as a sample for testing. The reflectance obtained is the working whiteness plate. calibration value. In daily work, the working whiteness board can be used to calibrate the instrument.

②Whiteness test Overlap several samples of 50mm×70mm, the long side of the sample is the vertical direction, until it is opaque, increase the number of samples to keep the whiteness value unchanged. Clamp the sample flatly on the test hole, the longitudinal direction of the sample is parallel to the irradiation light (that is, the long side of the sample is parallel to the front and back direction of the instrument), and after the display value of the instrument display is stable, read or record the display value as Whiteness of the sample. For the ZBD Whiteness Meter, use the reading knob to adjust the light point of the galvanometer to zero, and read the measured value with an accuracy of 0.1%. In each packaging unit, measure 3 pieces from the front and back sides of the different paper samples taken out, and the test results are expressed as the arithmetic mean of all measured values, and the maximum and minimum values are reported. After several samples are tested, the instrument should be recalibrated to ensure the test accuracy.

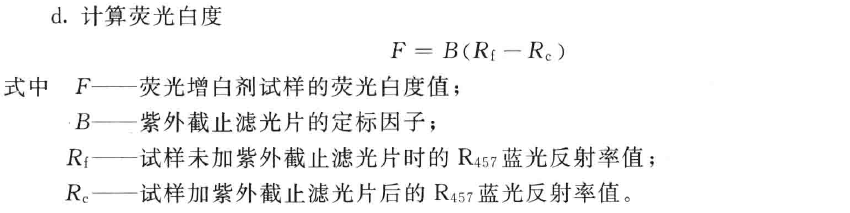

③Fluorescent Whiteness Test Fluorescent whitening is a physical phenomenon of photoluminescence. The whitening agent commonly used in paper is a chemical substance containing a double bond, which can increase the reflectance of blue light and improve the whiteness value. SBD Whiteness Meter adopts simulated D65 light source, which contains rich ultraviolet rays, so it can be used to measure fluorescent whiteness. The specific test steps are as follows.

a. After preheating the instrument, calibrate the instrument with a black tube and a non-fluorescent standard plate.

b. Place the fluorescent standard plate on the sample holder, and test the value Sf of its fluorescence R457. If Sf does not match the standard value S of the fluorescent standard plate, adjust the ultraviolet content of the instrument according to the instructions until Sf=S.

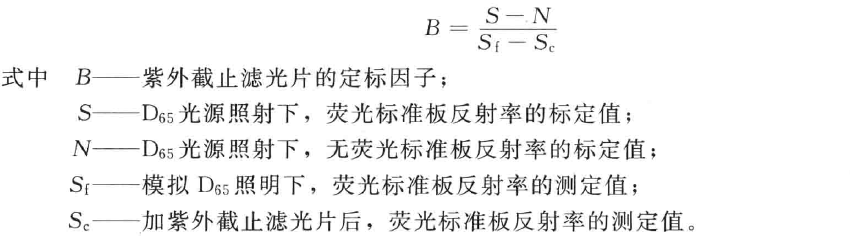

c. Eliminate ultraviolet radiation in the incident light with a UV cut-off filter, and repeatedly calibrate the instrument with a non-fluorescent working standard plate and a black cylinder. Measure the reflectance Sc of R457 of the fluorescent standard plate, and calculate the calibration factor of the UV cut-off filter of the instrument: