(1) Cardboard bursting test method

The test was carried out in accordance with the national standard GB 1539 "Determination of bursting strength of cardboard". The testing instrument is a Mullen Burst Tester or a 04BOM Burst Tester. The thickness of the film is (2.5±0.2) mm. The resistance of the film should be in the range of 156.8~189.0kPa when it is pressurized to protrude 9.5mm from the surface of the lower clamp ring. Film deformation should be replaced immediately. The specific test steps include the following points.

①Sample collection and processing According to GB 450 sampling, cut 10 samples of 100mm×100mm along the transverse direction of the paper web, 5 on the front and 5 on the back, and pre-treat the samples according to the requirements of GB 10739 on temperature and humidity.

② Press the sample tightly between the two sample holders to ensure that the sample will not slip during the test.

③Gradually increase the pressure at a rate of (170±15)mL/min until the sample bursts, and read the value indicated on the pressure gauge.

The test results are expressed as the arithmetic mean of all test results.

(2) Corrugated cardboard bursting test method

The test was carried out in accordance with the national standard GB 6545 "Determination of Bursting Strength of Corrugated Cardboard". The test principle is to place the sample on the film, clamp it with a sample clamp, and then apply pressure evenly to make the sample and the film protrude freely until the sample breaks. This standard applies to corrugated cardboard with a bursting strength of 350~5500kPa. The bursting strength of corrugated cardboard is determined by the hydraulic pressure increase method, that is, the maximum pressure that a unit area of corrugated cardboard can withstand under test conditions. The test instrument is Mullen type burst Tester or 04BOM burst Tester. The thickness of the film is (2.5±0.2)mm, and its upper surface is about 5.5mm lower than the top surface of the lower clamping ring. The material and structure of the film should make the height of the film protruding from the upper surface of the lower chuck suitable for the pressure . The specific test steps are as follows.

①Sample collection and processing: Sampling according to GB 450, cut 10 samples of 100mm×100mm along the transverse direction of the paper web, 5 on the front and 5 on the back, and pre-treat the samples according to the requirements of GB 10739 on temperature and humidity.

②Clamp the sample between the two clamp rings, start the burst Tester, gradually increase until the sample bursts, and read the indicated value on the pressure gauge .

The test results are expressed as the arithmetic mean of all measured values.

Because corrugated cardboard is made of face paper, inner paper and corrugated core paper, there is a gap in the middle, the cushioning performance is enhanced, but it is easier to be broken, so the burst resistance of corrugated cardboard is lower than that of the face paper, inner paper and corrugated core. The sum of the bursting strength of paper.

(3) 04BOM Burst Tester Test Method

① Check whether the selection of the clamping force of the sample is appropriate.

② Turn on the power and preheat the instrument for 30 minutes.

③Turn the three-position switch to the "MEM OFF" position, and use the "Zero" knob to adjust the bursting pressure to zero.

④ Turn the three-position switch to the "Check" position, and the pressure display will display the factory calibration value of the instrument, and the deviation should be within ±1%. If it exceeds, use the "GAIN" potentiometer to adjust.

⑤Turn the three-position switch to the "OP" working position to prepare for the test.

⑥Insert the sample, press the "START" button, the sample is clamped, the film bulges, and the sample is broken. Then the film will automatically return to its original position and read the burst value on the display.

⑦If the instrument needs to work automatically, the working cycle time can be selected from 0.5 to 3s, and the selection can be made by turning the "PAUSETIME" knob.

⑧If you need to interrupt the test, just press the "RETURN" button.

⑨If you need to stop the test in the middle of the test cycle, just press the "STOP" button, and the test will stop immediately.

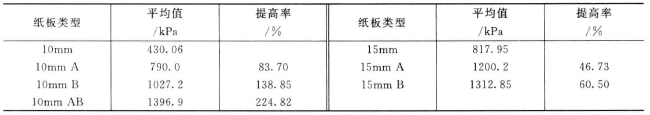

For example, the honeycomb sandwich is a regular hexagon, the diameter of the inscribed circle is 12mm, the surface paper is 300g/m2 recycled liner paper, and the core paper is 110g/m2 recycled paper. The surface paper of A and B single-sided corrugated boards is 200g/m2 cardboard paper, and the corrugated core is 175g/m2 corrugated base paper. "10mm A" means the corrugated-honeycomb single-sided composite structure cardboard formed by 10mm thick honeycomb paperboard and A single-sided corrugated cardboard, and "10mm AB" indicates the corrugated- Honeycomb double-sided composite structure cardboard, other abbreviations are similar. The burst test analysis results of these honeycomb paperboards and corrugated-honeycomb composite structure paperboards shown in Table 1 show that as the thickness increases, the burst resistance of honeycomb paperboards increases significantly, and the 15mm thick honeycomb paperboard is 90.19% higher than the 10mm thick honeycomb paperboard ; The bursting strength of the corrugated-honeycomb composite structure paperboard is significantly higher than that of the honeycomb paperboard. The bursting strength of 10mm A, 10mm B, and 10mm AB corrugated-honeycomb composite paperboards is significantly higher than that of 10mm thick honeycomb paperboards, and their bursting strengths are respectively 83.70%, 138.85% and 224.82% higher than that of 10mm thick honeycomb paperboards. The bursting strength of 15mm A and 15mm B type corrugated-honeycomb composite paperboard is significantly higher than that of 15mm thick honeycomb paperboard, and their bursting strength is respectively 46.73% and 60.50% higher than that of 15mm thick honeycomb paperboard.

Table 1 Corrugated-honeycomb composite structure paperboard burst test analysis results

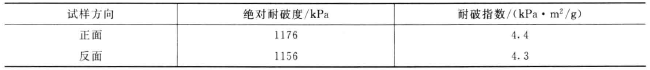

For another example, Table 2 shows the analysis results of the absolute burst strength and burst index of Tetra Pak packaging paper/plastic/aluminum composite materials. The vertical and horizontal directions of the cardboard have little influence on the puncture strength of this composite material.

Table 2 Analysis Results of Bursting Test of Paper/Plastic/Aluminum Composite Packaging Materials