(1) FRANK horizontal folding Tester

①Structure and working principle

The FRANK horizontal folding Tester is shown in the figure, suitable for measuring paper with a thickness of 0.25mm or less, or cardboard with a thickness of 0.25~1.4mm, and the folding angle is 180°. The 180° reciprocating folding movement of the folding instrument is performed by the motor and worm reducer installed at the back of the instrument, and the power is transmitted to the eccentric slider mechanism in the frame below the two identical folding heads. The stroke of the slider is based on the center point 10mm before and after the benchmark. The instrument has a printer interface on both sides of the front and rear counters, which can be connected to a printer to print out the test results.

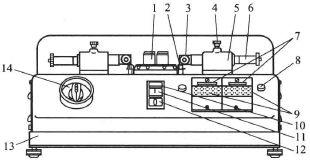

FRANK horizontal folding Tester

1-front and rear folding head; 2-slider; 3-sample clamp; 4-locking pin; 5-spring pillow seat; 6-tension rod; 7-clear key; 8-printer interface; 9-display; 10-Indicator light; 11-Work button; 12-Stop button; 13-Rack; 14-Power switch

②Main technical parameters

a. Folding angle: 180°.

b. Folding stroke: 10mm before and after the center point.

c. Sample size: when the sample thickness is less than or equal to 0.25mm, the sample size is 98mm×15mm, and the chuck distance is 90mm; when the sample thickness is greater than 0.25mm, the sample size is 140mm×15mm, and the chuck distance is 130mm.

(2) Test method

①Sample collection and processing

Take samples according to GB 450, cut the samples along the longitudinal and transverse directions of the paper web, and carry out temperature and humidity pretreatment on the samples according to the requirements of GB 10739.

②Pull out the locking pin on the fixed pillow of the sample clamp, so that the sample clamp is at the initial position. Press the reset key of the counter to make the display go to "0".

③ Loosen the screw on the sample clamp, clamp the sample in the middle of the two folding heads, do not damage the sample, then tighten the screw on the sample clamp, and stretch the sample clamp to the left and right sides to make the locking The pins are engaged and the specimen is tensioned.

④Press the working button to start the test until the sample is broken, read the value of the counter, that is, the number of folds of the sample. Return the counter to zero for the next test.

The test results are expressed as the arithmetic mean of all the measured values in vertical and horizontal directions, front and back, accurate to integer times, and the maximum and minimum values are reported.