(1)测试原理

黏合强度是描述瓦楞纸板楞峰与面纸(或芯纸)之间的粘接性能,单位是N/m。瓦楞纸板黏合强度的测试原理是,将针形附件插入瓦楞纸板试样的楞峰和面纸之间(或芯纸之间),然后对插有试样的针形附件施加压力,使其做相对运动,直至被分离部分分开。

瓦楞纸板的黏合强度为:

P=F/L

式中P——黏合强度,N/m;

F——试样全部分离时所需的最大力,N;

L——试样边长,m。

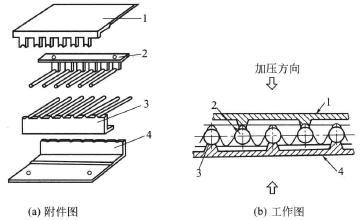

(2)试验架

瓦楞纸板黏合强度试验采用压缩试验仪和专用的试验架进行试验,试验架需要与压缩试验仪配套使用。压缩试验仪可选用弹簧板式压缩试验机或传感器式压缩试验仪。试验架如图2-58所示,图2-58(a)是组成试验架的附件图,图2-58(b)是试验架工作图。首先将针形附件插入瓦楞纸板楞峰、面纸(或芯纸)之间,然后对插有试样的针形附件加压,使其做相对运动,直至被分离部分分开。针形直径3mm用于A楞纸板,针形直径2mm用于C楞纸板。

图2-58;瓦楞纸板的剥离强度试验架

1-上压板;2-上针式件;3-下针式件;4-下压板

(3)测试方法

按照国家标准GB 6548“瓦楞纸板粘合强度的测定法”进行试验。具体测试步骤包括以下几点。

①试样采集与处理按GB450取样,用专用切刀沿纸幅切取25mm×80mm的10个试样,试样尺寸误差是±1mm,瓦楞方向与试样短边的尺寸线方向一致。按GB 10739的要求对试样进行温湿度预处理。

②将带有两排金属棒的针形附件插人试样的面纸和芯纸之间,并对好支撑柱,注意不要损坏试样。

③将安装好试样的附件放入压缩试验仪下压板的中央位置,开动仪器加压,以(12.5±2.5)mm/min的速度对装有试样的附件施加压力,直至楞峰、面纸(或芯纸)分离为止。读取仪器显示值,即试样所能承受的最大压力值,准确到1N。

④回复上压板,准备进行下一次试验。

⑤计算瓦楞纸板黏合强度。试验结果以10次试验的算术平均值表示试样的黏合强度﹐精确至0.001N/m。

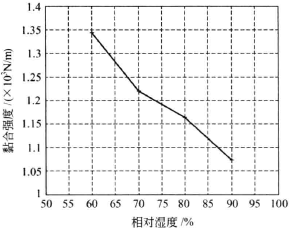

图2-59瓦楞纸板黏合强度与相对湿度的变化关系曲线

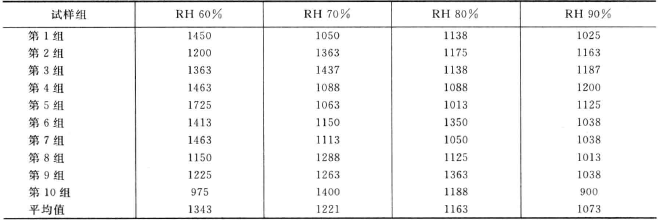

For example, for AB type double corrugated cardboard, the surface paper is 300g/m2 kraft paper, and the inner paper and core paper are 180g/m2 corrugated base paper. The test environment temperature is 20°C, and the relative humidity is selected as 60%, 70%, 80%, and 90%, respectively. The analysis results of the bonding strength test shown in Table 2-16 and Figure 2-59 show that the bonding strength of this type AB corrugated cardboard decreases significantly with the increase of the relative humidity of the environment, and the bonding strength at a relative humidity of 90% is higher than that of the relative humidity The bond strength at 60% decreased by about 20.1%. Because the adhesive used is starch adhesive, as the ambient humidity increases, the moisture absorption of the adhesive increases, which reduces the viscosity.