During the circulation process of filling, boxing, transportation, etc., glass packaging containers are often subjected to impact loads, thus forming vibration waves inside the container. Although this vibration wave will be reduced when it propagates in the glass and the contents, since the propagation direction of this vibration wave is different in all directions of the container, it will interfere with each other to generate tensile stress and compressive stress. In the direction of these stresses, it may cause damage to the glass bottle. Breakage is more likely to occur if there is tensile stress on the glass bottle surface prior to impact.

The impact strength tests of glass packaging containers are divided into mechanical shock, running shock, inclined plane impact, water shock and thermal shock resistance tests. This paper mainly introduces the test methods of mechanical impact strength, running impact strength, inclined plane impact strength and drop impact strength.

①Impact stress

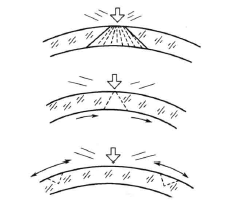

Figure 4-5 The stress distribution of the side wall of the glass bottle when it is impacted Figure 4-6 The damage pattern of the glass bottle when it is impacted

During the filling, packing, transportation, sales and use of glass bottles, the number of impacts, impact modes, impact waveforms, and impact sizes are very complicated. When the side wall of the glass bottle is impacted, local stress, bending stress and torsional stress are generated, as shown in Figure 4-5. The local stress causes the glass bottle to be partially depressed, and tensile stress is generated around it, resulting in conical scars or damage. During bending stress, the entire bottle wall is bent due to impact, and tensile stress is generated inside. Since the inner surface of glass bottles is generally free of scars, damage caused by bending stress is not common. The torsional stress is the stress generated at 45° of the impact point. Although it is much smaller (about 20%) than the previous two stress values, the actual damage is almost entirely caused by the torsional stress because the surface of the glass bottle is often scarred. of. Figures 4-6 show the damage patterns of glass bottles under local stress, bending stress and torsional stress. Figure 4-7 is the relationship curve between the impact strength and the wall thickness of the glass bottle. I and II represent the local damage area and the damage generation area respectively, a is the damage generation curve, and b is the strength failure curve.

Figure 4-7 The relationship between impact strength and glass bottle wall thickness

②Mechanical impact strength test

The national standard GB 6552 "Mechanical Shock Resistance Test Method for Glass Bottles and Cans" is applicable to the mechanical shock resistance test of glass bottles and jars. The test device used in the mechanical impact strength test is shown in Figure 4-8. It is mainly composed of a pendulum device , a clamping device, and a lifting mechanism.

Figure 4-8 Principle of pendulum impact test

1-lifting platform; 2-hitting object; 3-holder; 4-dial; 5-sample bottle; 6-height adjustment handle; 7-card board; 8-level adjustment handle

The mechanical impact strength test includes passing test and incremental test.

a. Passability test first place the sample bottle on the support platform, close to the rear support, adjust the support platform up and down, adjust the striking part of the glass bottle to the position to be detected, and adjust the support platform horizontally so that the pendulum In a free resting state, while the impact object lightly touches the surface of the vial. Then use the specified impact energy to repeatedly hit three points around the bottle body at a distance of about 120° to check whether the sample bottle is damaged.

b. The incremental test is basically the same as the passing test , but the impact energy needs to be gradually increased, and the test should be repeated until the sample bottle breaks.

③Running impact strength test

Figure 4-9 Running impact test device

1-top plate; 2,4-sample bottle; 3-bottle guide groove; 5-baffle plate; 6-speed motor

The test device is shown in Figure 4-9. The sample bottle is filled with the contents according to the specified volume requirements, and the cap of the bottle is tightened. Then start the transmission mechanism, the sample bottles collide with each other on the conveyor belt and are impacted, and observe the relationship between the speed of the conveyor belt and the rupture of the sample bottle. The transmission speed of the glass bottle without damage should be controlled within the range of 30-40m/min.

④ Inclined plane impact strength test

This test is suitable for detecting the rupture of the sample bottle when it is impacted in the horizontal direction during the circulation process after it is filled with the contents and boxed. The test method is similar to the inclined plane impact test method for transport packages .

⑤ Drop impact strength test

The drop impact strength refers to the damage caused by the glass bottles and jars filled in the whole box being freely dropped from a height of 1m on a wooden board in three ways: vertically, horizontally, and obliquely (with the mouth facing upward). It is actually the impact strength. Combined result with water flushing intensity.