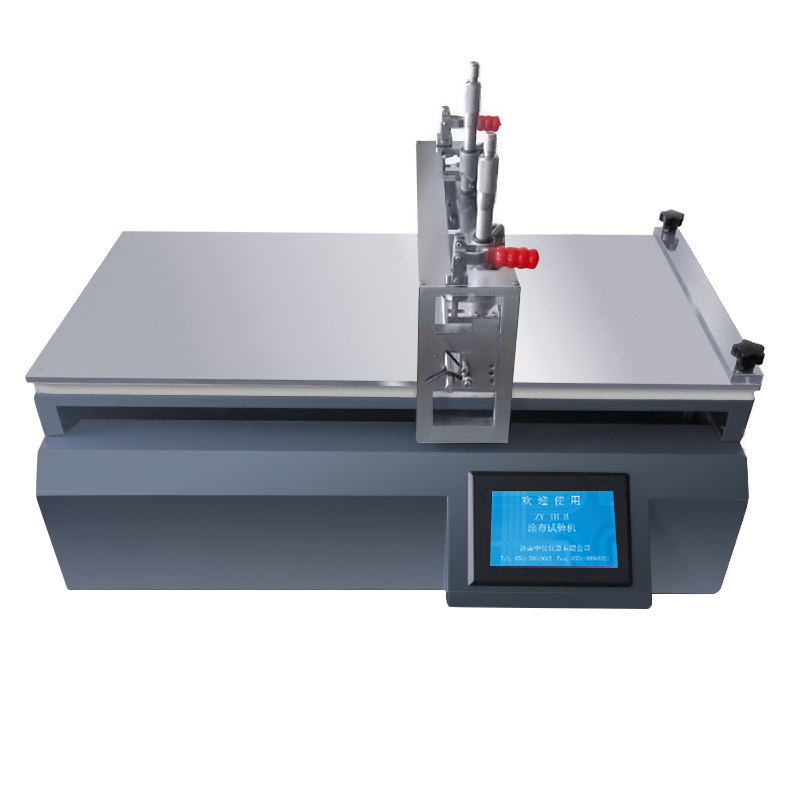

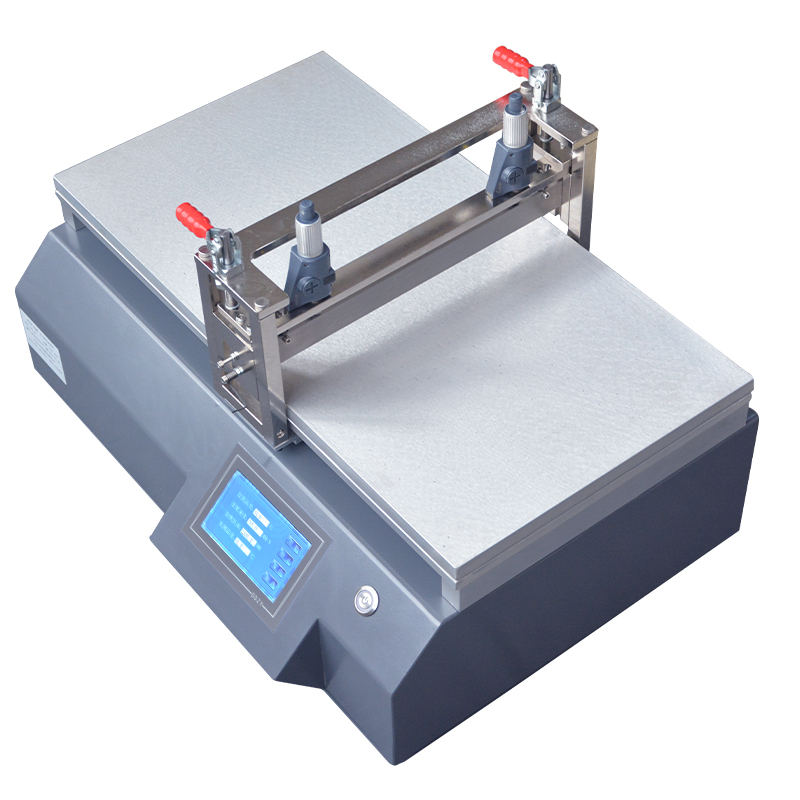

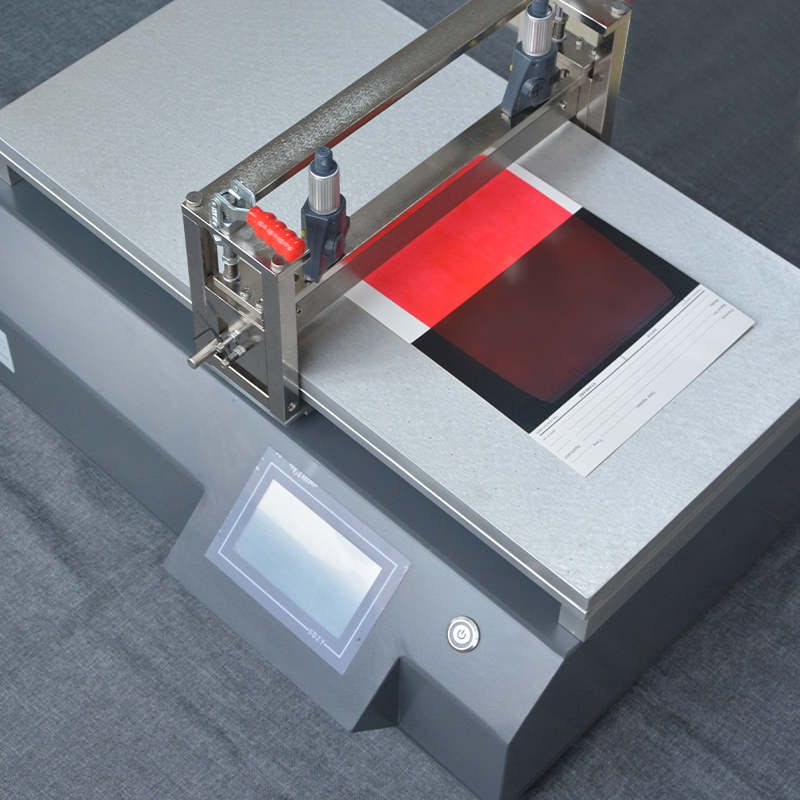

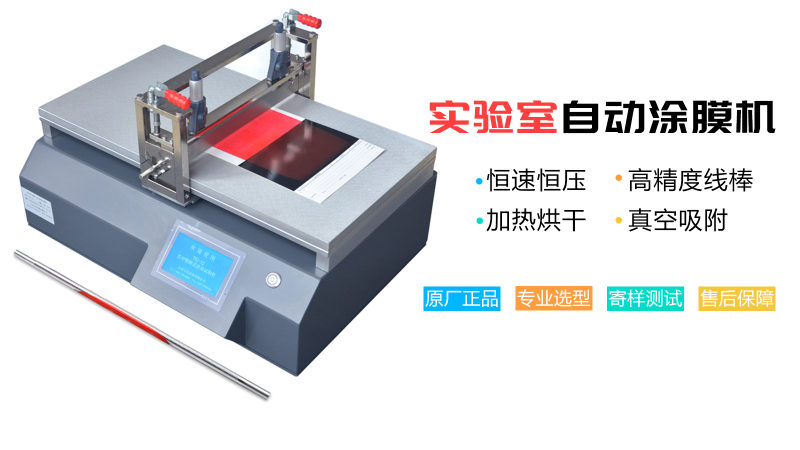

This is a small experimental coating machine with heating function, the bottom plate is made of aluminum alloy. Aluminum alloy? Why not stainless steel? We all know that many industrial products use various grades of stainless steel for better anti-corrosion effects, such as stainless steel Viscosity Cups, stainless steel fineness plates, stainless steel applicators, etc. But why does it become an aluminum plate when it comes to the heating coater?

This paper mainly analyzes this problem. This is due to the difference in properties between stainless steel and aluminum.

As a heating type film coating machine, the bottom heating wire is used to heat the bottom plate, and the temperature of the bottom plate is transferred to the sample. Therefore, the thermal conductivity of the base plate is very important. In addition, the melting points of different metals are different, and there must be a problem with heat deformation.

Stainless steel is relatively deformable, and its thermal conductivity is poorer than aluminum alloys. When we heat stainless steel, due to its slow heat transfer rate, the part that is heated first will generate thermal expansion first, and the adjacent area will not get the same amount of heat in time because of its slow heat transfer rate. , there will not be too much thermal expansion, which will cause the excess material in the previous thermal expansion area to have nowhere to extend and arch up and down, thereby driving the entire material to deform and twist. Aluminum has better thermal conductivity and will not deform.

In addition, from the perspective of cost, aluminum alloy is a little lower than stainless steel. Therefore, on the whole, the performance and cost performance of aluminum alloy are higher than that of stainless steel.