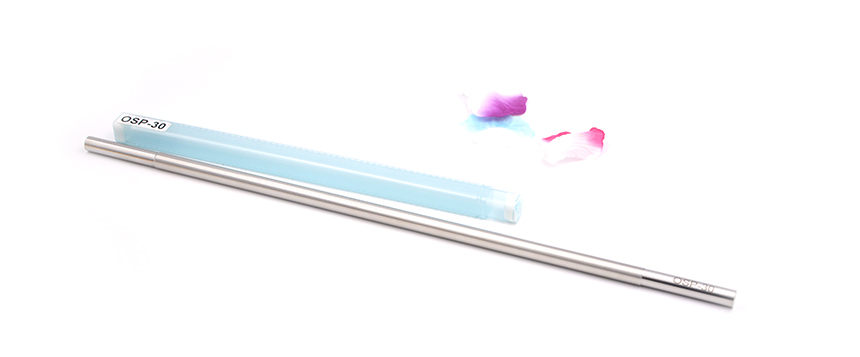

OSP wire Bar Coater is an extruded stainless steel coating wire bar. OSP-30/400 has a coating film thickness of 30μm and a coating width of 300mm. And it can be coated on an automatic film coating machine. Although many coating experiments require the same 30μm, but because different users have different perceptions and trusts in brands, different requirements for coating, and different requirements for grades, there are many types of wire Bar Coaters that need to be selected. Different brands and models are used for reference, and the model that meets the overall needs of users is selected.

This issue of the editor is mainly to share which other models in the industry can be replaced with OSP-30/400, and what are the specific differences.

At present, imported American RDS, British RK and domestic wire rods all have rod numbers that can scrape and coat 30μm film thickness, and have the following rod numbers.

| Membrane Proofing- Membrane | |

| OSP OSP-30/60 Wire Bar Coater L60 |

| Specification parameters: production process extrusion type, wet film thickness 30μm, diameter 10mm, total length 60mm, coating width 60mm, hand grip width 0, material 304 stainless steel | |

| OSP OSP-30/250 Coating Stick L250 |

| Specification parameters: production process extrusion type, wet film thickness 30μm, diameter 10mm, total length 250mm, coating width 250mm, hand grip width 0, material 304 stainless steel | |

| RDS 13# 1/4" coating stick 1/4" |

| Specification parameters: production process wire winding type, wet film thickness 29.7μm, diameter 6.35mm, total length 400mm, steel wire diameter 0.33mm, coating width 300mm, hand grip width 50mm, material stainless steel | |

| RDS 13# 3/8" coating stick 3/8" |

| Specification parameters: production process wire winding type, wet film thickness 29.7μm, diameter 9.52mm, total length 400mm, coating width 300mm, hand grip width 50+50mm, material stainless steel, steel wire diameter 0.33mm | |

| RDS 13# 1/4" Form Coating Stick 1/4" |

| Specification parameters: production process extrusion type, wet film thickness 29.7μm, diameter 6.35mm, total length 400mm, coating width 300mm, hand grip width 50+50mm, material stainless steel | |

| RDS 13# 3/8" Form Coating Rod 3/8" |

| Specification parameters: production process extrusion type, wet film thickness 29.7μm, diameter 9.52mm, total length 400mm, coating width 300mm, material stainless steel | |

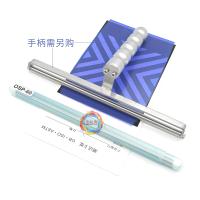

| Yongchao Technology D10-YC030-L400mm experimental coating metering rod |

| Specification parameters: production process extrusion type, wet film thickness 30μm, diameter 10mm, total length 400mm, coating width 310mm, hand grip width 45+45mm, material stainless steel 304, surface technology chrome plating | |

The film thickness of the above wire Bar Coaters is 30μm, but the length and process of the wire bar are different. For example, RDS has a wire-wound process, and OSP has two coating widths of 60mm and 250mm.